1 t/h fish & shrimp feed plant in bangladesh

Fish & Shrimp Feed Plant (Turnkey Project)

Production of expanded fish feed and shrimp feed

Feed Specifications:

2-8 mm fish feed and 0.5-2.5 mm shrimp feed

Raw Materials:

Corn, soybean meal, rice bran, wheat bran, mustard oil cake, sesame cake, fish meal, meat and bone meal, vegetable oil, and vitamin and mineral premixes…

Production Capacity:

1 ton per hour

Type:

Fish & Shrimp Feed Plant

bangladesh AQUACULTURE MARKET

As the world’s fifth-largest aquaculture country, Bangladesh has nearly 2 million hectares of water dedicated to aquaculture, primarily producing shrimp, crab, and fish. Around 60% of the country’s animal protein intake comes from fish, making aquaculture crucial to the country’s food security and nutritional. With rising populations and incomes, demand for tilapia, catfish, and shrimp has surged—driving commercial feed consumption.

Bangladesh’s feed market focuses mainly on fish feed. Tilapia feed has seen the fastest growth due to its fast growth rate and disease resistance. Common local favorites like catfish and carp maintain steady feed demand. While shrimp feed requires advanced technology, it remains highly profitable as a premium segment.

Despite strong prospects, Bangladesh’s aquaculture feed market faces numerous challenges.

The most significant issue is that feed raw materials (fishmeal, soybean meal, corn) are largely imported. The market also suffers from counterfeit and low-quality feeds. Furthermore, many small-scale aquaculture farmers lack scientific knowledge or funds to afford quality feed.

Bangladesh’s aquatic feed market has two future development directions.

It can focus on developing specialized extruded floating feeds tailored to different species and growth stages. This type of feed reduces waste and improves nutrient absorption. Functional feeds with added probiotics and immune enhancers are becoming a mainstream market trend, reducing disease risk for fish and shrimp. Furthermore, Local alternatives like insect protein/algae to replace imports, cutting costs while utilizing domestic resources.

CLIENT PROJECT DETAILS

This customer from southern Bangladesh has been working in the aquaculture feed industry for many years, holding management positions in several local feed companies. He deeply understands fish and shrimp feed formulations, market demand, and equipment performance.

As Bangladesh’s aquaculture industry continues to expand, he realized a shortage of high-quality feed locally. Thus, he decided to invest with several partners in building a fish and shrimp feed plant with an hourly production capacity of approximately one ton, aiming to supply quality extruded feed to nearby farmers.

Customers hope that their new aquatic feed processing factory can achieve the following goals:

- Producing both fish and shrimp feed on the same production line;

- Offering a wide range of pellet sizes, from 0.5mm to 8mm;

- Providing feed with good feed formation, strong water stability, and balanced nutrition;

- Having a stable and easy-to-operate production system, facilitating future expansion.

Bangladesh’s feed raw material supply system is relatively mature. And customers can easily obtain local common raw materials such as corn, soybean meal, rice bran, wheat bran, mustard oil cake, sesame cake, fish meal, meat and bone meal, and vegetable oil, and add vitamin and mineral premixes to supplement nutrition.

When designing the factory plan, RICHI considered the differences in protein levels and high oil content of these raw materials, and optimized the crushing and extrusion systems to make the density of feed pellets more controllable and the molding more stable.

CUSTOM-TAILORED SOLUTION

No two customers have exactly the same aquaculture feed production needs. In the aquaculture industry, different aquaculture species and fish growth stages have different requirements for feed pellet size and nutritional composition.

RICHI always puts the real needs of customers first. Before providing a feed production solution, we researched customers’ core pain points:

Do you have access to raw materials? What types are available?

Do you have planned production capacity estimates?

Should the production line support flexible switching switch between multiple recipes?

What is the desired timeline for installation and commissioning?

Based on this information, we design a more tailored solution for the customer, ensuring that fish & shrimp feed equipment configuration and process design are fully aligned with customers’ specific needs, helping them resolve operational challenges.

Our Bangladeshi customer built this fish & shrimp feed plant specifically to sell feed commercially. Although its his first time investing as factory owners, he had worked in aquatic feed industry for many years and was familiar with all aspects of feed production. So after discussing with his partners, they finally decided to arrange a full set of equipment for this 1t/h fish & shrimp feed plant.

The final fish & shrimp feed plant primarily includes the following parts:

Raw Materials Processing

Through screening and magnetic separation, remove corn cobs from corn, lumpy/hardened shells from soybean meal, and small bone fragments from fishmeal. Discard moldy particles to prevent equipment damage or feed safety risks.

Next, further group materials by hardness/density differences, with hard and light materials separately to avoid mixed feeds that could lead to uneven pellet size.

01

Crushing System

The classified raw materials are put into the ultrafine grinder in batches, where they are precisely ground into a uniformly sized fine powder.

Because each type of raw material is crushed independently, it can avoid cross-contamination and lay a foundation for the uniform fusion of nutrients in the mixing process.

02

Mixing System

According to the preset feed formula ratio, ground basic raw materials are put into the mixing equipment, and then functional additives such as vitamins, minerals, and probiotics are added.

The mechanical stirring of the feed mixer is used to achieve full fusion of the materials.

03

Extrusion System

Because the customers wanted to produce extruded feed, and for cost considerations, we equipped with a twin screw extruder here, which can process both fish and shrimp feed.

When customers want to change the feed pellet size, they simply replace the ring die.

04

Drying System

Feed pellets just out of the extruder contain high moisture content. They are evenly dried by the drying system, which can make the pellets have appropriate moisture content while maintaining the nutrients, avoiding caking and affecting the subsequent attachment of additives.

05

Spraying System

The spraying system is typically started after the drying process, mainly to deposit functional substances onto the surface of dried feed pellets.

High-pressure atomizing nozzles evenly spray oils, flavorings, enzymes, and probiotics onto the pellet surface. And combined with a drum stirring function, the sprayed substances are fully contacted with the pellets and uniformly attached.

06

Drying System

It processes dry, high-temperature feed pellets after spraying.

By circulating cold air, the pellet temperature is quickly lowered to near room temperature. This prevents hot pellets from entering the packaging process, potentially causing thermal deformation of the packaging material and seal failure.

07

Packaging System

The terminal is equipped with a fully automatic packaging machine. It can automatically complete the weighing, filling and sealing of finished fish/shrimp feed particles, and simultaneously labels the bags with the production date, specifications, and shelf life.

Once packaged, customers can directly arrange to load the car for sale or store it in the warehouse.

08

bangladesh FISH & shrimp FEED Plant CONFIGURATION

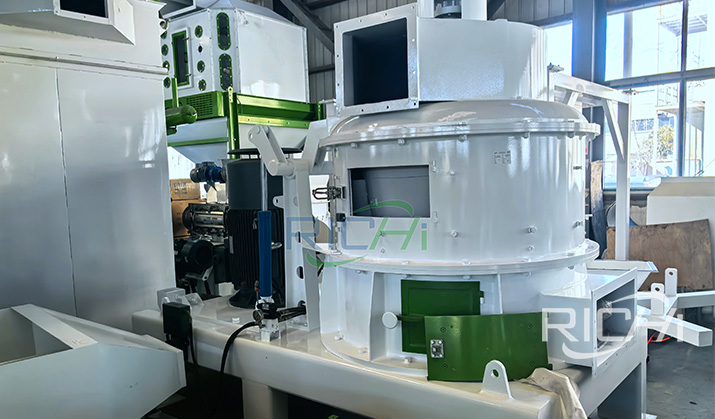

For the 1 ton/hour fish and shrimp feed plant construction project in Bangladesh, all equipment on this feed production line was independently developed and manufactured by RICHI Machinery. We offer quality guarantees and lifetime after-sales service.

The equipment used in this feed processing plant includes a cylindrical primary cleaner, an ultra-fine grinder, a twin shaft paddle mixer, a twin screw extruder, a mesh belt dryer, a vaccum sprayer, a counter-flow cooler and a fully automatic packaging machine. These machines for producing fish feed and shrimp feed were custom-designed to meet the production capacity of the plant.

01

Raw Materials Processing

cylindrical primary cleaner

02

Crushing System

Ultrafine Grinder

03

Mixing System

Twin Shaft Paddle Mixer

04

Extrusion System

twin screw extruder

04

Drying System

Mesh Belt Dryer

05

Spraying System

Vaccum Sprayer

07

Cooling System

Counter-flow Cooler

08

Packaging System

fully automatic packaging machine

Complete fish & shrimp feed plant delivery process

Machine Production

After the customer confirmed the plan and signed the contract, our factory immediately began production. All feed equipment used in this 1-ton/hour fish & shrimp feed plant is self-manufactured by RICHI, with some key components custom-made based on the customer’s raw material type and process needs.

During production, our engineers rigorously monitor every step—from material selection to assembly and commissioning—following unified quality standards to ensure reliable performance and stable operation.

At the same time, to let customers know the progress more, we regularly capture photos and videos of the equipment manufacturing process, showcasing key equipment and semi-finished products. In this way, customers can clearly see the whole process of step-by-step molding of the whole production line even if they are not on site.

Equipment Delivery

Once all fish & shrimp feed production equipment is fully manufactured and the necessary accessories for the fish & shrimp feed production line are prepared, we will arrange shipment according to the delivery schedule confirmed with you.

As a long-established manufacturer in the feed equipment industry, we have a mature global delivery system. Our feed production equipment has been successfully exported to over 140 countries and regions.

Whether your project is located in Côte d’Ivoire or elsewhere, we can ensure the safe and timely delivery of the equipment to the project site through standardized logistics solutions and end-to-end tracking services.

Installation, Commissioning, and Training

After the equipment arrives at the customer’s project site, we offer flexible installation support options: You can install it yourself or have our engineers assist on-site.

For this project, the customers chose self-installation. To ensure a smooth installation, we provided detailed installation drawings in advance and provided online guidance. If any problems arise during installation, our technical team will timely provide solutions to get the line running smoothly.

After the feed production line is installed and commissioned, we provide customers with training, either online or on-site. This training covers equipment operation, routine maintenance, and production process management, ensuring safe and skilled use of the entire feed production line.

In addition, the feed production machinery used in our designed feed production projects comes with a warranty period. After installation, our after-sales service team will proactively monitor equipment operation. Even after the warranty expires, customers can still reach out anytime for expert support, and we’ll promptly supply any needed spare parts.

Customer evaluation and project operation status

Six months after the fish and shrimp feed mill began operating, our after-sales team received a review from our Bangladeshi customer about the fish & shrimp feed plant we designed for them:

“This 1-ton-per-hour fish and shrimp feed production line is our first ever self-invested feed factory. Yeah, we’ve worked in the aquatic feed industry before, but building an entire factory from scratch? That’s a first for us.

RICHI team was super thorough right from the planning stage—they helped us go through all the details, like raw materials, production volume, and the types of feed we need to make. The whole production line they set up is really well-suited for us.

Once the equipment arrived, we organized the installation ourselves. But the RICHI engineers were there the whole time with online technical guidance and commissioning support. The whole process went really smoothly. Now the factory’s running steadily—we hit a good production volume every day, and the feed quality has also won over the fish farmers.”

Bangladesh Fish & Shrimp Feed Plant: Value and Trend

This fish/shrimp feed plant in Bangladesh effectively fills the local aquatic feed supply gap, helps improve fish and shrimp production and quality, and drives growth across related industrial chains while creating numerous jobs locally.

Currently, the pace of specialized and functionalized aquatic feed production in Bangladesh is accelerating. Future feed factories must integrate extrusion technology, precise nutritional formulas, and promote the use of local alternative raw materials, moving the industry from from traditional extensive production to an efficient, green, sustainable model.

Types of feed suitable for production in Bangladesh

Bangladesh is a major aquaculture and livestock farming country, and different farming species have varying feed nutritional requirements, pellet specifications, and raw material choices.

Combined with the abundant local grains, oilseed meal and fishery by-products, sorted out several kinds of feed types that are most suitable for production in Bangladesh, helping farmers and feed producers to quickly understand the key needs of the local market.

(1)Aquatic Feed

Bangladesh has rivers everywhere and ponds all over, creating perfect conditions for farming tilapia, catfish, shrimp, and other aquatic products.

Fish Feed

Tilapia, catfish and carp (expanded floating feed)

Shrimp Feed

Penaeus monodon/Penaeus vannamei (pellet size 0.8-2mm)

(2)Poultry Feed

Poultry products are a major source of animal protein in Bangladesh, and the market is stable and the demand continues to grow. Feed production needs to design reasonable formula according to different poultry varieties and growth stages.

Broiler Feed

Layer Feed

Duck Feed

Duck farming is popular in some parts of Bangladesh, especially in areas close to rivers, lakes and other waters. Ducks can not only provide duck meat and eggs, but also have certain economic value.

(3)Ruminant Feed

Bangladesh is rich in agricultural by-products, such as rice straw, wheat bran and sugarcane tips, which are ready-made roughage resources.

Cattle Feed

Sheep Feed

(4)Specialty Animal Feed

Pet Feed

Tip: At present, the penetration rate of family pets in urban areas of Bangladesh is still low, so it is necessary to avoid over-reliance on the high-end pet feed market.

Quail/Pigeon Feed

Designed for quails and pigeons raised domestically or commercially.

OUR PROJECTS IN OTHER COUNTRIES

The 1 t/h fish & shrimp feed plant in Bangladesh has been running smoothly until now. This case of stable operation is the embodiment of RICH’s strength in the field of aquatic feed equipment for many years. All along, we have been focusing on the research and development of aquatic feed production equipment and the whole line delivery, and our business map has covered many markets around the world, including Russia, Kyrgyzstan, Kazakhstan, Uzbekistan, Azerbaijan, Iran, India, Nigeria, and other countries and regions. With our reliable equipment quality and comprehensive service, we’ve earned long-term trust from global customers.

If you are planning a fish feed production line or a fish feed mill, choose RICHI as your trusted partner. We will tailor professional equipment solutions and full-process technical assistance to help you launch operations quickly and achieve steady profits.

5 tons/hour fish feed production line in Russia

This production line, which is built by our company and can produce floating feed pellets and sinking fish feed pellets, adopts advanced twin screw extrusion technology, and the produced feed pellets also have super water stability, which can be kept in water for 12 hours. This production line has made remarkable achievements since it was put into production.

2.5 Tons/Hour Fish Feed Production Line In Kyrgyzstan

This project successfully overcame the specific requirements of feed extrusion technology in high-altitude regions, providing a cost-effective, localized feed solution for salmon and trout farming. It can make good use of local common corn and soybean meal, as well as local protein ingredients like flaxseed meal. By precisely controlling conditioning temperature and pelleting parameters, it produces feed pellets for sinking fish such as grass carp and rainbow trout.

3-5 tons/hour fish feed factory in Kazakhstan

Designed by RICHI, this 3–5 tons/hour fish feed production line features a twin-screw extruder and multiple grading screens. The biggest highlight is that the production capacity can be flexibly switched according to the market demand—running at full capacity of 5 tons/hour during peak season and dropping to 3 tons/hour during off-season. This not only saves energy but also reduces costs. This line can produce feed for both coldwater and freshwater fish.

1 ton/hour floating fish feed production equipment in Uzbekistan

This production line is specifically designed based on the raw material availability in Uzbekistan, such as cottonseed meal and wheat bran, which can be easily bought locally. By adjusting the formula, the protein content of the feed is maintained within an appropriate range, meeting the nutritional needs of fish at different growth stages. has successfully filled the supply gap for high-end floating fish feed in the local market.

1-2 tons/hour fish feed processing plant in Azerbaijan

Tailored to the aquaculture demands along the Caspian Sea, this production line allows for easy switching between sturgeon feed and conventional fish feed. Considering the high sand content of some raw materials in Azerbaijan, we’ve also added an impurity removal device to the line, significantly reducing wear and and enhancing machinery durability.

2 Tons/hour fish feed production line in Nigeria

This production line features strong raw material adaptability and weather resistance, effectively tackling West Africa’s climatic challenges. It can make efficient use of cassava flour, palm kernel meal and other raw materials commonly used locally to produce high-quality feed that meets the needs of main varieties such as tilapia.

RICHI Guarantee

RICHI Machinery began as a professional manufacturer in feed pellet machine, and has now developed into a comprehensive solution partner for both feed pellet equipment and complete pellet plant systems. We take great pride in our team’s expertise and skills—from technical sales to process design engineers, every member is committed to supporting our customers. You can confidently choose RICHI to elevate your business.

In the field of aquatic feed pelletizing equipment and full aquatic feed pellet production lines, we leverage our team’s extensive experience to accurately understand your process engineering needs, deeply solve practical challenges, and tailor-made reliable solutions that meet international high standards for you.

Custom Design

Every customer’s production needs are unique, so we offer full custom design services. From production capacity and raw material type to product specifications, each production line is tailored to the customer’s actual conditions, ensuring efficient layout, optimized performance, and flexibility for future expansion.

Extensive Experience

Founded in 2013, our company has years of experience in the feed machinery industry. Whether it’s a stand-alone feed production machine or a turnkey feed production project, we can provide the perfect feed production solution.

Professional Service Team

From early consultation to solution design, equipment production, and after-sales service, we have a highly comprehensive and professional team whose members are fully committed to completing the project.

Competitive Advantage

We have a production facility covering over 60,000 square meters, and customers can visit our factory at any time. Our equipment has been exported to over 140 countries and regions worldwide, with very high customer satisfaction.

WHAT FEED PROCESSING SOLUTIONS CAN WE PROVIDE?

We can design and build complete feed pellet production lines and turnkey feed pellet machines with capacities from 1 to 100 tons per hour for all types of aquatic organisms and animals.

Aquatic Feed Production Line

Fish, shrimp, crab, shellfish and other conventional aquaculture species and special aquatic animals

Pet food production line

Cats, dogs, hamsters, turtles…

Poultry & Livestock feed production line

Chicken, duck, goose, pigeon, pig…

ruminant feed production line

Cattle, sheep, horses, deer, camels…

Multi-functional feed production line

Flexible switching between multiple categories