10 T/H Salmon & Trout Feed Production Line in Norway

Fully Automated Fish Feed Production Line (Customized Project)

Application:

Producing floating fish feed

Feed Specifications:

3-6 mm

Raw Materials:

Fish meal, fish oil, seaweed, barley, oats, soybeans, rapeseed meal

Production Capacity:

10 tons per hour

Type:

Salmon & Trout Feed Production Line

norway AQUACULTURE MARKET

Norway ranks among the world’s leading salmon farming nations, with its expanding aquaculture sector fueling continuous demand for fish feed. A handful of major producers dominate this market, focusing on premium species such as salmon and trout. Due to the government’s ongoing promotion of efficient and sustainable aquaculture practices, the entire feed market has grown steadily in size while increasingly relying on technological innovation to maintain competitive edges.

Yet Norway’s feed production remains heavily dependent on imported ingredients like fishmeal, fish oil, and soybean meal. Price volatility in these commodities directly affects production costs.

Meanwhile, stricter environmental standards require feed companies to reduce emissions and alleviate pressure on marine ecosystems, posing real challenges.

Although the industry is experimenting with new ingredients like insect meal and microalgae protein, their limited availability and high cost make them difficult to fully replace traditional formulations in the short term.

Going forward, three trends will likely shape Norway’s feed market:

Greater use of alternative proteins to cut import dependency; increased incorporation of locally sourced materials within circular economy frameworks; and development of precision nutrition strategies that improve feed efficiency, nutritional value, and eco-friendliness.

CLIENT PROJECT DETAILS

This project is initiated by a seasoned professional with over ten years of experience in the Nordic feed industry. He has worked for several international feed companies, deeply involved in nutritional formulation development and production management for salmon and trout, giving him mature insights into Norway’s aquafeed market.

As the industry evolves, he noticed that despite Norway being a global leader in salmon production, there remains significant market potential for small to medium-sized feed mills, especially in customized feed solutions, localized supply chains, and sustainable ingredient applications.

Based on this observation, he co-founded a new aquafeed company with three partners. Their vision is to build a modern, high-efficiency, eco-friendly, and smartly automated factory that meets the growing demand for premium floating feed in the region.

The plan involves constructing a 10-ton-per-hour fully automatic production line for salmon and trout feed in western Norway’s aquaculture hub. This line will specialize in high-performance floating feed suitable for major grow-out stages.

Formulations will center around high-protein sources like fishmeal, fish oil, and seaweed, combined with regionally available agricultural by-products such as barley, oats, soy, and rapeseed meal—striking a balance between nutrition and sustainability.

The entire system features sealed, modular, and customizable design, complying with stringent EU and Norwegian food safety and environmental standards, including GMP+, NS 9402, and REACH. It also allows future integration of carbon footprint tracking systems.

From raw material intake to extrusion, drying, coating, and packaging, every step is automatically controlled, ensuring consistent floating performance, nutrient retention, and batch-to-batch uniformity.

CUSTOM-TAILORED SOLUTION

RICHI always puts the real needs of customers first. Before providing a feed production solution, our engineers conducted a detailed consultation with the client:

What is the target fat/oil content of the finished pellets?

Does the finished product cooling equipment need special design to adapt to Norway’s cold and humid environment?

Do we need to consider the location of outdoor oil storage tanks and fishmeal silos?

Are there any special requirements regarding energy consumption?

Based on this information, we design a more tailored solution for the client, ensuring that salmon and trout feed pellet equipment configuration and process design are fully aligned with clients’ specific needs, helping them resolve operational challenges.

As requested by the clients from Norway, the equipment configuration of this 10 ton/hour salmon & trout feed production line is very complete.

The finalized salmon & trout feed production line primarily includes the following sections:

Pre-processing System

Before raw materials enter the production line, they first pass through a drum pre-cleaner to remove impurities like rope fragments, stones, and lumps.

This step is an essential basic stage for high-capacity fish feed lines.

01

Crushing System

The 10T/H salmon feed requires high grinding precision, so a two-stage process is used:

① Coarse Grinding: A hammer mill grinds bulk plant-based ingredients (barley, oats, rapeseed meal, soybeans, etc.) to medium fineness, preparing them for further processing.

② Fine Grinding: Salmon and trout feed formulas contain high-protein materials like fishmeal and seaweed powder, which require finer particles to improve pellet stability. This is done by a fine grinder.

02

Mixing System

Twin shaft paddle mixer ensures high mixing accuracy and speed, thoroughly blending protein sources, grains, and micro-ingredients.

Some liquid additives can be added at this stage (though high-fat components are typically handled in the coating system).

03

Extrusion System

High-fat, high-protein salmon and trout feed requires a twin screw extruder to enhance cooking, expansion, and overall pellet stability.

Twin screws allow better control over density and shape.

04

Drying System

Extruded pellets immediately enter a multi-layer belt dryer to reduce moisture content to a safe level. Temperature zones are controlled separately to protect nutrients in sensitive ingredients like fish oil and seaweed.

05

Spraying System

This is a crucial stage in premium fish feed production.

Vacuum coating evenly absorbs large amounts of fish oil or algal oil into the pellet core, making the feed more energy-dense, non-leaking, and non-sticky.

It’s key to achieving high-fat, high-energy formulations for salmon and trout.

06

Cooling & Screening System

After coating, pellets remain slightly warm. Counter-flow air cooling gently lowers temperature, hardening the pellets and reducing breakage.

Cooled pellets then pass through sieves to separate qualified products from oversized pieces and dust. Fines can be returned for re-pelletizing, improving material utilization.

07

Packaging System

Final products move via conveyor to fully automatic packaging machines for weighing, filling, and sealing.

Pack sizes can be customized for Norwegian market needs, such as 20kg, 25kg, or large 1-ton bags.

Automated packaging reduces labor costs and keeps the entire 10T/H line running continuously and efficiently.

08

Norway salmon & trout FEED Production LINE CONFIGURATION

For the 10t/h salmon & trout feed production line in Norway, all fish feed equipment on the line was independently developed and manufactured by RICHI Machinery. We offer quality guarantees and lifetime after-sales service.

01

Pre-processing System

Cylindrical Primary Cleaner

02

Crushing System

Hammer Mill

03

Mixing System

Ultrafine Grinder

04

Mixing System

Twin Shaft Paddle Mixer

05

Extrusion System

Twin Screw Extruder

06

Drying System

Mesh Belt Dryer

07

Cooling & Screening System

Counter-flow Cooler & Screener

08

Packaging System

Ton Bag Scale

Complete Floating & sinking fish feed production line delivery process

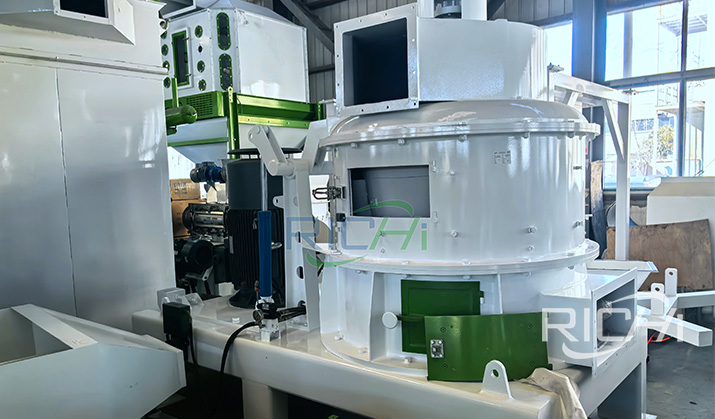

Machine Production

After the client confirmed the plan and signed the contract, our factory immediately began production. All feed equipment used in this 10 ton/hour salmon & trout feed production line in Norway is self-manufactured by RICHI, with some key components custom-made based on the customer’s raw material type and process needs.

During production, our engineers rigorously monitor every step—from material selection to assembly and commissioning—following unified quality standards to ensure reliable performance and stable operation.

At the same time, to let customers know the progress more, we regularly capture photos and videos of the equipment manufacturing process, showcasing key equipment and semi-finished products. In this way, customers can clearly see the whole process of step-by-step molding of the whole production line even if they are not on site.

Equipment Delivery

Once all salmom and trout feed equipment is fully manufactured and the necessary accessories for the fish feed production line are prepared, we will arrange shipment according to the delivery schedule confirmed with you.

Whether your project is located in Norway or elsewhere, we can ensure the safe and timely delivery of the equipment to the project site through standardized logistics solutions and end-to-end tracking services.

Installation, Commissioning, and Training

After the equipment arrives at the customer’s project site, we offer flexible installation support options: You can install it yourself or have our engineers assist on-site.

For this project, the client chose to have our engineers assist with the installation and commissioning on-site. After the feed production line was installed, our engineers provided systematic training for their staff, covering equipment operation, daily maintenance, and process management.

The feed production machinery used in our designed feed production projects comes with a warranty period. After installation, our after-sales service team will proactively monitor equipment operation. Even after the warranty expires, clients can still reach out anytime for expert support, and we’ll promptly supply any needed spare parts.

CLIENT evaluation and project fUTURE

“We brought in a salmon and trout feed production line from RICHI last year. To be honest, we hesitated a lot before making this decision—it was no small investment, after all, and we’d been using equipment from well-established European manufacturers all along. But the end result has been totally satisfying.

Once, when we were making high-fat feed, there was a little glitch with the oil injection system, which made the oil distribution in that batch of feed uneven. We were pretty stressed about it and contacted them right away. To our surprise, they responded super quickly—they diagnosed and fixed the problem in no time through a video call, and later even updated the operation manual specifically for us.

This incident actually put our minds at ease even more. Because reliable after-sales service beats any sales pitch hands down. It’s been a partnership that’s well beyond our expectations.”

Norway Salmon & Trout Feed Production Line: Value and Trend

Localized salmon and trout feed production lines ensure more stable and flexible supply, reducing reliance on imports and long queues at large factories.

More Norwegian feed producers are now seeking production solutions that save energy, use diverse raw materials flexibly, and require simpler maintenance.

Types of feed suitable for production in norway

Norway’s farming structure is very distinct, so the types of feed suitable for production are also clear. It primarily focuses on marine fish feed, followed by livestock feed.

(1)Aquaculture Feed

Norway’s aquaculture is a world-class industry, making aquatic feed the most important and in-demand category locally.

Salmon Feed

Norway is the world’s largest salmon producer, with long-term, stable demand for salmon feed.

Trout Feed

Trout is one of Norway’s main freshwater farmed species.

Cod & Halibut Feed

This type of feed represents an emerging growth direction for Norway.

(2)Livestock & Poultry Feed

Although not as large-scale as aquatic feed, Norway still has stable local demand from its livestock sector, suitable for producing conventional pellet feed.

Cattle and Sheep Feed

Norway has abundant grassland resources, with cattle and sheep farming distributed nationwide.

Chicken Feed

(3)Fur Animal Feed – Unique To Norway

Norway was historically one of the world’s major fur animal producers. Although the industry’s scale has decreased, there are still a number of mink and fox farms.

OUR PROJECTS IN OTHER COUNTRIES

For 30 years, RICHI has specialized in fish feed production machinery, driven by tech and backed by service. We create flexible solutions deployed successfully worldwide – from Russia, Ukraine through Central Asia ( Uzbekistan, Azerbaijan) to United States, Malaysia, Philippines, India, Iran, Ecuador – adapting to various climates, ingredients, and aquaculture requirements.

1-2 tons/hour fish feed processing plant in Azerbaijan

Tailored to the aquaculture demands along the Caspian Sea, this production line allows for easy switching between sturgeon feed and conventional fish feed. Considering the high sand content of some raw materials in Azerbaijan, we’ve also added an impurity removal device to the line, significantly reducing wear and and enhancing machinery durability.

RICHI Guarantee

RICHI Machinery began as a professional manufacturer in feed pellet machine, and has now developed into a comprehensive solution partner for both feed pellet equipment and complete pellet plant systems. We take great pride in our team’s expertise and skills—from technical sales to process design engineers, every member is committed to supporting our customers. You can confidently choose RICHI to elevate your business.

Custom Design

Extensive Experience

Professional Service Team

Competitive Advantage

WHAT FEED PROCESSING SOLUTIONS CAN WE PROVIDE?

Fish, shrimp, crab, shellfish and other conventional aquaculture species and special aquatic animals

Poultry & Livestock feed production line

Chicken, duck, goose, pigeon, pig…

ruminant feed production line

Cattle, sheep, horses, deer, camels…

Multi-functional feed production line

Flexible switching between multiple categories