2 T/H shrimp feed pellet line in Indonesia

Shrimp Feed Pellet Line (Turnkey Project)

Production of shrimp feed

Feed Specifications:

0.6-8 mm

Raw Materials:

Fish meal, yeast powder, soybean lecithin, wheat bran, soybean meal..

Production Capacity:

2 tons per hour

Type:

Shrimp Feed Pellet Line

Indonesia AQUACULTURE MARKET

Indonesia is the largest archipelagic country in the world, with vast sea areas and extremely rich aquatic resources, which has laid a natural foundation for its developed aquaculture and fishing industry.

For this reason, Indonesia’s aquatic products market has formed a very distinct pattern, and the core categories are catfish, tilapia and various shrimps. Among them, Java Island and Sumatra Island are the two core aquaculture producing areas in Indonesia, while Bagan Siabia Fishing Ground on the east coast of Sumatra Island is a world-famous natural fishing ground, which delivers high-quality seafood to domestic and international markets all the year round.

In recent years, the Indonesian government has deliberately increased its investment in fishery development, and under the impetus of policies, the aquaculture industry has flourished all the way.

But the industry is on fire, and new demand is coming-now the market demand for high-quality aquatic feed is particularly large and urgent. Unfortunately, Indonesia’s local high-end feed production capacity can’t keep up, especially the shrimp feed and high-end puffed fish feed with the highest technical difficulty, and the gap is quite obvious.

This is a rare market opportunity for feed enterprises with advanced technology and production or investors who invest in the feed industry.

For these individuals, it is undoubtedly the key to seize the blue economic opportunity in Southeast Asia to deeply participate in the Indonesian aquatic product market, especially to make a strategic layout in the field of high-tech and high value-added aquatic feed.

CLIENT PROJECT DETAILS

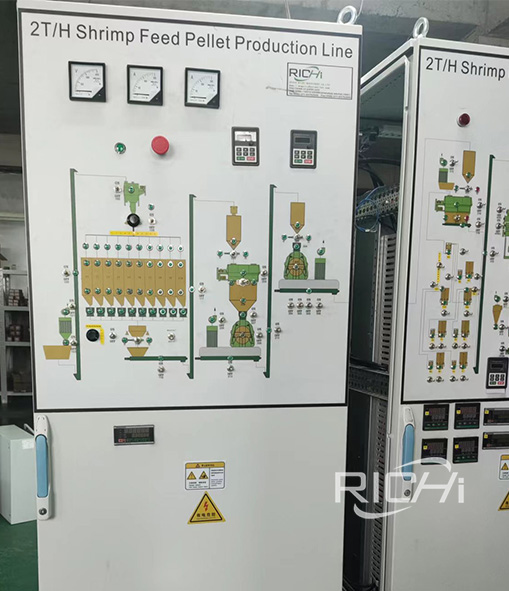

This shrimp feed pellet production project is located in Indonesia. It is mainly used to produce shrimp feed (sinking feed). It is shrimp feed production line with a relatively high degree of automation.

After the customer decided to invest in building a fish feed This customer is located in the eastern part of Indonesia. Seeing the huge market and potential in the shrimp feed field in the region, he decided to invest in building a shrimp feed pellet mill.

But for the customer, this is a relatively large project and a turnkey project, so the customer is more cautious when choosing a manufacturer. Before looking for shrimp feed pellet machine manufacturers, the customers already had a comprehensive plan and program, and clearly knew what kind of manufacturer they needed.

Therefore, when looking for shrimp feed pellet machine manufacturers, the scope was relatively narrow, and they quickly found us. They thought that we were a more professional shrimp feed pellet machine manufacturer and could complete their investment and factory construction plan, so they quickly chose us.

The customer hopes to improve the local shrimp feed farming situation through this shrimp feed pellet line, so he attached great importance to this project and communicated with our designers and engineers many times before finalizing the production plan.

At present, the shrimp feed pellet mill has been officially put into operation and has achieved very good results locally.

CUSTOM-TAILORED SOLUTION

The main raw materials used in this shrimp feed pellet line are fish meal, yeast powder, soybean lecithin, wheat bran, soybean meal, etc. In addition, there are vitamins, oils, premixes and other substances that need to be added to the feed.

These raw materials can be used to produce shrimp feed pellet of different lengths from 0.6 to 8 mm through this shrimp feed pellet line to meet the growth and development of shrimp feed of different species and growth stages.

This production line is a shrimp feed pellet line with a relatively high degree of automation. The entire production process includes batching system, crushing system, mixing system, pelleting system, cooling system and packing system. The machine in each section is relatively complete, and it is a relatively complete shrimp feed pellet line.

Batching System

The customer initially planned to use manual batching, but considering that there are many types of raw materials for shrimp feed production and manual batching requires more workers, the final solution was to use automatic batching. We designed 10 raw material warehouses for the customer.

01

Crushing System

Since the raw materials for shrimp feed production are mostly high in fat, high in protein and low in starch, it is difficult to crush them. In addition, the crushing particle size of the raw materials for shrimp feed production is relatively high, so it is crushed twice. The hammer mill is used for both crushing operations.

02

Mixing System

The whole production process requires two mixings. The first is after the batching is completed, using mixer to mix the materials; the second is after the two crushings are completed, vitamins, additives and other materials need to be put into the mixer through the small material feeding port and mixed with the crushed materials.

03

Pelleting System

The production line is equipped with shrimp feed pelletizer with three-layer modulator. Both feed extruders and feed pelletizers can be used to produce shrimp feed, but from an economic perspective, the cost of shrimp feed pelletizers will be lower, so the customer decided to use shrimp feed pelletizers after comprehensive consideration.

04

Cooling System

The feed pellets coming out of the pellet mill are at high temperature. If you want to quickly cool them to room temperature, you need to use feed cooler.

Below this feed cooler is crumbler, and the crushed small feed pellets can be used to feed shrimps. The crumbler used for shrimp feed is fine-size crumbler that can crush pellets to about 0.6mm.

05

Packing System

After the cooled shrimp feed pellets are screened, the qualified shrimp feed pellets are sent to the packing machine for packing.

Shrimp feed pellets can be packed into 10-50 kg/bags of shrimp feed through the packing system, which is easy to store and transport and can meet different sales needs.

06

INDONESIA SHRIMP FEED PELLET LINE CONFIGURATION

For the 2 t/h shrimp feed pellet line in Indonesia, all equipment on this mill was independently developed and manufactured by RICHI Machinery. We offer quality guarantees and lifetime after-sales service.

The equipment used in this project includes a crusher, a mixer, a shrimp feed pellet machine, a counter-current cooler, and a ton bag scale. These feed production equipment were custom-designed to meet the production capacity of the 2 T/H shrimp feed pellet line.

01

Batching System

Batching Scale

02

Crushing System

Hammer Crusher

03

Mixing System

Single Shaft Paddle Mixer

04

Pelleting System

Shrimp Feed Pellet Machine

05

Cooling System

Stainless Steel Cooler

06

Packing System

Ton Bag Scale

Complete SHRIMP feed pELLET line delivery process

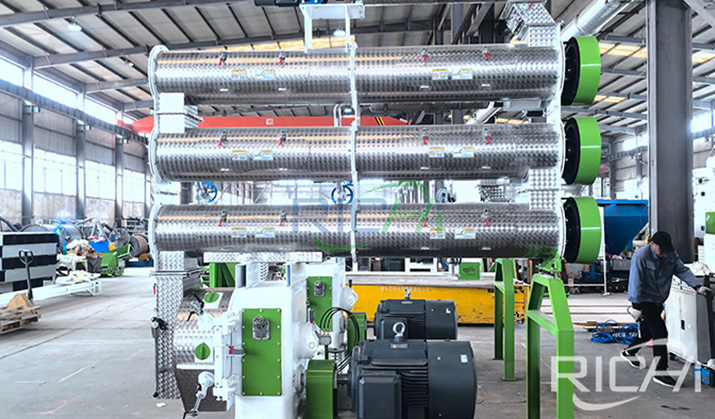

Machine Production

This is customized shrimp feed pellet line. All the machine used in the shrimp feed pellet line, such as shrimp feed pelletizer, crumbler, etc., are customized according to customer needs.

So when the plan of the shrimp feed pellet line is determined and the contract is signed, our factory begins to arrange the production plan for all the equipment needed for this shrimp feed pellet line.

The production cycle of this shrimp feed pellet line is 60 days, which is two months. During the two-month production period, we will regularly send customers pictures and videos of the equipment that has been produced or some semi-finished products of the equipment, so that customers can understand the entire production process of the equipment they purchased.

Equipment Delivery

Once all shrimp feed pellet production equipment is fully manufactured and the necessary accessories for the shrimp feed pellet are prepared, we will arrange shipment according to the delivery schedule confirmed with you.

As a long-established manufacturer in the feed equipment industry, we have a mature global delivery system. Our feed production equipment has been successfully exported to over 140 countries and regions.

Whether your project is located in Indonesia or elsewhere, we can ensure the safe and timely delivery of the equipment to the project site through standardized logistics solutions and end-to-end tracking services.

Installation, Commissioning, and Training

After the equipment arrives at the customer’s project site, we offer flexible installation support options: You can install it yourself or have our engineers assist on-site.

For this project, the customer chose to have our installation team provide on-site guidance for the installation out of caution.

After installation, our engineers commissioned the entire shrimp feed pellet line. They then provided basic training to the customer’s staff on equipment operation, routine maintenance, and production process management.

In addition, the feed production machinery used in our designed feed production projects comes with a warranty period. After installation, our after-sales service team will proactively monitor equipment operation. Even after the warranty expires, customers can still reach out anytime for expert support, and we’ll promptly supply any needed spare parts.

Customer evaluation and project operation status

From installation to production, this Indonesian customer witnessed the performance of RICHI shrimp feed pellet equipment all the way:

“We’re a local shrimp feed company in Sumatra, mainly supplying shrimp farms in North Sumatra and the Riau Islands. Last year, we brought in that 2-ton-per-hour shrimp feed pellet production line you designed—and honestly, this set of shrimp feed pelleting equipment has been such a nice surprise for us!

Right from the start of installing this 2-ton/hour shrimp feed pellet line, we could tell it was different. Your engineers were so thoughtful: they looked into the quality of the palm kernel meal and fish meal we use here ahead of time, and even worked out a voltage stabilization plan based on our factory’s power supply. What’s even more considerate is that the control cabinet has a moisture-proof seal—you know, our workshop gets pretty humid, so with this design, we never have to worry about short circuits anymore.

Now this shrimp feed pellet line has been running steadily for over ten months. We run two shifts a day, and it basically hits full production capacity. Plus, the shrimp feed pellets it makes are super even, with neat cuts, and they hold up really well in water. The shrimp farmers all say that when they feed their shrimp with our feed, the shrimp eat well, and their survival rate has gone up a lot too.

We really want to thank you for helping us make good shrimp feed right here in Indonesia!”

Indonesia Shrimp Feed Pellet Line: Value and Trend

In Indonesia, modern shrimp feed pellet lines do more than just cut waste and ensure consistency—they’re essential for intensive shrimp farming. As BFT systems spread and export standards rise, locally made traceable feeds with specific functions have become mandatory. In the future, producers offering flexible capacity, stable quality, and fast response will win farmer trust and dominate this high-potential market.

Types of feed suitable for production in Indonesia

As an archipelagic nation with vast waters and rapid population growth, Indonesia centers its feed sector on aquaculture feed and poultry feed. While smaller in scale, ruminant feed also offers growth opportunities.

(1)Aquaculture Feed

This is Indonesia’s most critical, fastest-growing, and profitable segment.

Shrimp Feed

Indonesia ranks among the world’s top shrimp producers. High-quality sinking pellets for Litopenaeus vannamei are an absolute necessity and highly competitive.

Tilapia/Catfish Feed

These fish provide mainstream protein for local consumers—demand is massive. Sinking or slow-sinking expanded pellets dominate production volume here.

Grouper/Sea Bass Feed

Rising demand for high-value marine species follows offshore cage culture expansion; expanded pellets lead this trend.

Channa striata Feed

A prized local predatory fish—developing dedicated feed could tap into unmet market potential.

(2)Poultry Feed

Indonesia’s most mature livestock sector demands consistent quality at scale.

Broiler Feed

Requires phase-specific formulations (starter, grower, finisher), primarily based on corn & soybean meal.

Layer Feed

Split into grower and layer phases; precise mineral (Ca, P) and amino acid balance is essential.

(3)Ruminant Feed

Poultry industry is the most mature animal husbandry industry in Iran, and the demand for feed has been great and stable.

Beef Cattle Supplement feed

Concentrates paired with palm kernel cake/cassava residue accelerate weight gain on large-scale lots.

Dairy Cow Concentrate Feed

Target dairy farms near cities to boost milk yields.

Palm Byproduct-Based Feed

Leveraging Indonesia’s status as the world’s largest palm oil producer—cost-effective roughage from palm press fiber holds huge potential.

OUR PROJECTS IN OTHER COUNTRIES

The 1.5-2 t/h extruding fish & shrimp feed production line in Iran has been running smoothly. This case of stable operation is the embodiment of RICH’s strength in the field of aquatic feed equipment for many years. All along, we have been focusing on the research and development of aquatic feed production equipment and the whole line delivery, and our business map has covered many markets around the world, including Russia, Kyrgyzstan, Kazakhstan, Azerbaijan, Bangladesh, Iran, India, Nigeria, and other countries and regions. With our reliable equipment quality and comprehensive service, we’ve earned long-term trust from global customers.

If you are planning a fish feed production line project, choose RICHI as your trusted partner. We will tailor professional equipment solutions and full-process technical assistance to help you launch operations quickly and achieve steady profits.

2.5 Tons/Hour Fish Feed Production Line In Kyrgyzstan

This project successfully overcame the specific requirements of feed extrusion technology in high-altitude regions, providing a cost-effective, localized feed solution for salmon and trout farming. It can make good use of local common corn and soybean meal, as well as local protein ingredients like flaxseed meal. By precisely controlling conditioning temperature and pelleting parameters, it produces feed pellets for sinking fish such as grass carp and rainbow trout.

3-5 tons/hour fish feed factory in Kazakhstan

Designed by RICHI, this 3–5 tons/hour fish feed production line features a twin-screw extruder and multiple grading screens. The biggest highlight is that the production capacity can be flexibly switched according to the market demand—running at full capacity of 5 tons/hour during peak season and dropping to 3 tons/hour during off-season. This not only saves energy but also reduces costs. This line can produce feed for both coldwater and freshwater fish.

5 tons/hour fish feed production line in Russia

This production line, which is built by our company and can produce floating feed pellets and sinking fish feed pellets, adopts advanced twin screw extrusion technology, and the produced feed pellets also have super water stability, which can be kept in water for 12 hours. This production line has made remarkable achievements since it was put into production.

1-2 tons/hour fish feed processing plant in Azerbaijan

Tailored to the aquaculture demands along the Caspian Sea, this production line allows for easy switching between sturgeon feed and conventional fish feed. Considering the high sand content of some raw materials in Azerbaijan, we’ve also added an impurity removal device to the line, significantly reducing wear and and enhancing machinery durability.

2 ton/hour Shrimp Feed Plant in Bangladesh

Bangladesh is a major shrimp exporter in South Asia, and the requirements for the pellet uniformity and water resistance stability of shrimp feed are strict. RICHI designed a 2 ton/hour shrimp feed plant for a local customer. This line adopted ultra-fine grinding technology and a double-layer conditioner to ensure uniform nutrition in feed particles and long water resistance, and to avoid the shrimp pond from being polluted by feed collapse when shrimps eat.

2 tons/hour fish feed processing Plant in Nigeria

This processing palnt features strong raw material adaptability and weather resistance, effectively tackling West Africa’s climatic challenges. It can make efficient use of cassava flour, palm kernel meal and other raw materials commonly used locally to produce high-quality feed that meets the needs of main varieties such as tilapia.

RICHI Guarantee

RICHI Machinery began as a professional manufacturer in feed pellet machine, and has now developed into a comprehensive solution partner for both feed pellet equipment and complete pellet plant systems. We take great pride in our team’s expertise and skills—from technical sales to process design engineers, every member is committed to supporting our customers. You can confidently choose RICHI to elevate your business.

In the field of aquatic feed pelletizing equipment and full aquatic feed pellet production lines, we leverage our team’s extensive experience to accurately understand your process engineering needs, deeply solve practical challenges, and tailor-made reliable solutions that meet international high standards for you.

Custom Design

Every customer’s production needs are unique, so we offer full custom design services. From production capacity and raw material type to product specifications, each production line is tailored to the customer’s actual conditions, ensuring efficient layout, optimized performance, and flexibility for future expansion.

Extensive Experience

Founded in 2013, our company has years of experience in the feed machinery industry. Whether it’s a stand-alone feed production machine or a turnkey feed production project, we can provide the perfect feed production solution.

Professional Service Team

From early consultation to solution design, equipment production, and after-sales service, we have a highly comprehensive and professional team whose members are fully committed to completing the project.

Competitive Advantage

We have a production facility covering over 60,000 square meters, and customers can visit our factory at any time. Our equipment has been exported to over 140 countries and regions worldwide, with very high customer satisfaction.

WHAT FEED PROCESSING SOLUTIONS CAN WE PROVIDE?

We can design and build complete feed pellet production lines and turnkey feed pellet machines with capacities from 1 to 100 tons per hour for all types of aquatic organisms and animals.

Aquatic Feed Production Line

Fish, shrimp, crab, shellfish and other conventional aquaculture species and special aquatic animals

Cats, dogs, hamsters, turtles…

Poultry & Livestock feed production line

Chicken, duck, goose, pigeon, pig…

ruminant feed production line

Cattle, sheep, horses, deer, camels…

Multi-functional feed production line

Flexible switching between multiple categories