3-5 t/h fish feed plant

Customized 3-5 tons per hour fish feed factory turnkey project for sale, including fish feed factory process design, fish feed production plan design, and a full set of fish feed production equipment.

What is 3-5 t/h fish feed plant?

A 3-5 ton/hour fish feed plant is

a complete production system capable of stably producing 3–5 tons of aquatic feed pellets per hour.

It’s suitable for the large-scale production of floating fish feed, sinking fish feed, and some shrimp feed.

It’s not just a simple combination of equipment, but a comprehensive engineering solution covering raw material handling, extrusion pelletizing, drying and cooling, oil spraying/coating, and sieving & packaging. This allows for high-output, continuous production at lower operating costs.

Production capacity

(tons/hour)

3-5

Pellet size

(mm)

0.5-12

As a leading global manufacturer of feed machinery and equipment, we have been deeply involved in the production of floating fish feed for nearly 30 years. We can provide you with a complete set of equipment

What are its key features?

Customizable pellet size and shape

(e.g., 1mm shrimp feed pellets, 2mm fish feed pellets) to meet different fish/shrimp feeding needs.

Equipped with a post-pelleting oil coating system,

which can increase the fat content of pelleted feed, meeting the demand for high-fat content in most pelleted fish feed.

Features an ultra-fine grinder with high grinding fineness,

effectively improving the quality of both fish and shrimp feed.

An automatic batching system

improves efficiency and increases precision requirements for ingredients in feed formulas.

The entire fish feed production line can

work continuously and efficiently, achieving the goal of factory-scale pellet production.

The feed production line has

a reasonable design, and each production section can be added or removed based on customer needs.

What Can a 3–5 T/H Fish Feed Plant Produce?

A 3–5 ton/hour fish feed plant falls into the medium-capacity range and can accommodate the production of various types of aquatic feeds and some pet foods. Depending on the process configuration, it can stably produce the following common feed types:

Floating Fish Feed

Floating pellets are currently the fastest-growing market segment. Using advanced extrusion technology, high-fat fish feed pellets can be produced, which stay suspended in water for longer periods.

Target species: Tilapia, carp, catfish, ornamental fish, etc.

Pelletizer type: Extruders (dry type extruder, wet type extruder, twin screw extruder)

Sinking Fish Feed

Conventional sinking fish feed is usually produced using pelletizing technology. However, with advancements in feed production technology, fish feed plants now also use extrusion to produce sinking fish feed, overcoming the shortcomings of traditional pelletized sinking feed.

Target species: Sturgeon, grouper, marine fish, shrimp

Pelletizer type: Pellet mill, extruder

Slow-Sinking Feed

There is also considerable market demand for slow-sinking fish feed, which consists of pellets that fall between floating and sinking types, suitable for mid-to-bottom-feeding species.

Target species: Catfish, yellow catfish, snakehead fish, seabass, turbot

Pelletizer type: Single/Twin screw extruder

Custom Aquatic & Pet Feeds

A 3–5 ton/hour fish feed plant isn’t limited to just fish feed; it’s a versatile production line capable of handling fish feed, shrimp feed, and even pet food.

Types: Shrimp, crab feed, specialty aquatic feed, mid-to-high-end pet food

Pelletizer type: Extruders, often twin screw extruders

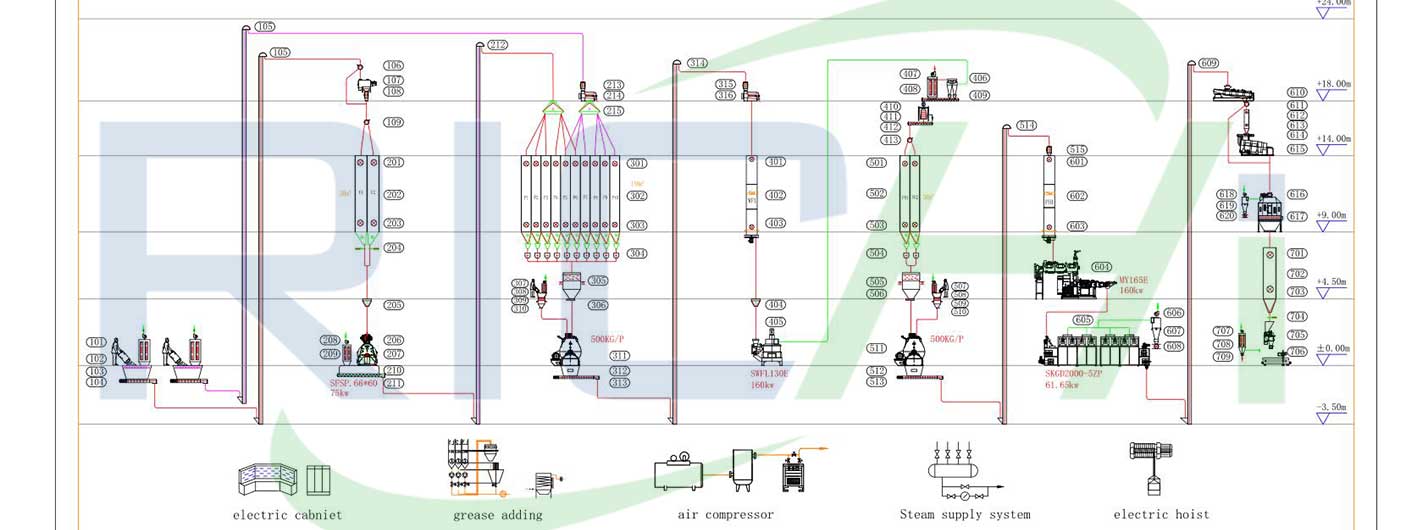

composition of A 3-5 t/h fish feed plant

To build a 3–5 ton/hour fish feed plant, beyond basic requirements like factory layout and process design, the most crucial step is selecting a stable and efficient, complete fish feed production line.

A mature fish feed production line enables automated and continuous operation from raw material reception to finished pellet packaging, thereby increasing the efficiency of fish feed pellet production.

With years of experience in building fish feed plants, RICHI has successfully created hundreds of proven fish feed production solutions for clients worldwide.

Here is the typical production process we designed for a 3-5 ton/hour fish feed production line:

●

Raw material processing

Raw materials first undergo cleaning, impurity removal, and weighing. This ensures that the materials entering the production line are clean, consistent, and free of contaminants, laying a solid foundation for subsequent grinding and formula control.

●

Crushing of raw materials

A grinder processes materials like corn, soybean meal, and fishmeal down to the required fineness. The more uniform the grind, the better the stability of the feed’s floatability, binding properties, and digestibility.

●

Automatic batching and mixing

All ingredients are thoroughly mixed according to the formula ratio. This critical step ensures every batch has uniform nutrition and no separation, guaranteeing feed quality.

●

Pelleting/Extrusion

Pellet formation takes place in a pellet mill or an extruder. An extruder can also control the expansion level, density, and floating/sinking properties, which determine the final quality of the product.

●

Drying

Freshly made wet pellets are quickly and evenly dried to reduce their moisture content to a safe level, preventing mold and extending shelf life.

●

Spraying

Sensitive nutrients like fats, probiotics, and attractants are added evenly at low temperatures. This enhances the energy value, palatability, and market appeal of the product.

●

Cooling & Screening

Hot pellets are cooled to set their shape. At the same time, powder and broken pellets are sifted out, ensuring the finished pellets have a uniform size, a cleaner appearance, and greater stability for packaging.

●

Packaging

The line automatically weighs, bags (typically in 50kg or larger sizes), and seals the final products, creating packaged feed ready for sale.

Main equipment used in A 3-5 t/h feed

production line

A complete feed production line requires many pieces of equipment, including main machines like grinders, mixers, extruders, and belt dryers, as well as many auxiliary devices such as conveyors, silos, and cleaning equipment.

RICHI can provide all the necessary feed production equipment, and we manufacture these machines ourselves. With a production workshop of over 60,000 square meters, modern manufacturing facilities, and a professional team, we can guarantee the quality of every piece of feed machinery.

Our factory welcomes every customer to visit at any time. We also invite you to come to our company to discuss your ideas.

Six Major Plant Types: Which 3–5 Ton/Hr Production Line to Choose?

3-5 Ton/Hr Fish Feed Pellet Mill

A medium-capacity line that can stably produce floating, sinking, and various other types of aquatic feed.

It features a mature, highly adaptable process, suitable for factories with multiple formulas or those serving various farmed species.

Can be configured with single-screw, wet, or twin-screw extrusion systems to meet different density and quality requirements.

3-5 Ton/Hr Floating Fish Feed Pellet Mill

This production line specializes in high-expansion, strongly-floating fish feed pellets, often used for markets like tilapia, grass carp, carp, and perch.

Its core equipment is an extruder, which allows for stable control of cooking level, pellet density, and expansion rate.

It’s ideal for clients looking to create brand-oriented, differentiated floating feeds.

3-5 Ton/Hr Sinking Fish Feed Pellet Mill

Meets the production needs for conventional or premium sinking fish feed, offering a choice between a ring die pellet mill or an extruder.

Ring die is suitable for high-volume, cost-sensitive products; extrusion is better for high-protein, high-fat, and more palatable formulas.

The entire line can support the large-scale production of sinking feed for species like tilapia, catfish, blunt-snout bream, and marine fish.

3-5 Ton/Hr Shrimp Feed Pellet Mill

Specialized in producing high-density, water-stable shrimp feed pellets (semi-floating or sinking).

The line typically includes a twin-screw extruder or a ring die pellet mill, allowing for precise control over pellet hardness, shape, and micro-level size.

It’s designed for the shrimp farming market, including species like Pacific white leg shrimp, giant freshwater prawn, and tiger shrimp.

3-5 Ton/Hr Pet Food Pellet Pellet Mill

Used for producing pet food pellets like dog and cat food.

It comes equipped with a twin-screw extruder, a precision coating system, and controlled drying/aging processes to meet the demands for high-fat, high-palatability, and high-expansion products.

It can manufacture various types of pet food, such as complete diets, grain-free kibble, high-protein foods, and puffed snacks, making it a mainstream capacity for entering the pet food market.

3-5 Ton/Hr Multi-functional Feed Pellet Mill

This is a hybrid production line compatible with both aquatic and livestock/poultry feed.

It’s suitable for the large-scale production of aquatic feeds (for fish, shrimp, crab) as well as common animal pellets (for chicken, duck, goose, cattle, sheep).

The line uses a modular design: the aquatic feed section can use an extruder, while the livestock/poultry section uses a ring die pellet mill. This setup allows for switching between different product lines based on orders.

Who is suitable to invest in a 3-5 t/h fish feed plant?

The 3–5 ton/hour capacity is considered medium-scale for fish feed production. It offers high flexibility and a moderate investment, making it the most popular output range globally. Generally, the following clients are best suited for this capacity:

① Small and Medium-sized Feed Processing Plants (Expanding/Upgrading)

For processing plants that already have a market presence but face clear production bottlenecks, a 3–5 ton/hour line is the most cost-effective solution for expansion. It provides continuous, stable, medium-scale output while being compatible with floating, sinking, and even some shrimp feed production. This allows you to quickly increase sales without the high costs associated with a large-scale factory.

② Traders/Distributors with Formulas & Channels (Transitioning to Private Label)

If you already have established sales channels and a loyal customer base but rely on third-party manufacturers, this production line can help you capture the profits for yourself. The 3–5 ton/hour capacity is sufficient to supply a regional market. Combined with an extruder’s flexible product adjustment capabilities, it makes it easy for you to create differentiated, own-brand products.

③ Large-scale Aquaculture Farms (Looking to Reduce Feed Costs)

For farms with high annual feed consumption where feed expenses are a major cost, investing in a 3–5 ton/hour line can significantly lower your feed costs. You can fully customize the formula according to your specific fish species, size, and feeding strategy. This results in more palatable pellets, better floatability, and more stable survival and conversion rates.

④ Entrepreneurs Wanting to Produce Fish Feed + Some Pet Food

With its strong compatibility, a 3–5 ton/hour line is one of the most common choices for small, multi-product feed factories. By selecting the right extruder model, you can produce floating fish feed, sinking fish feed, and even expand into entry-level pet food on the same system. This helps you reach a broader market, increasing the line’s utilization rate and profit margins.

Investment Cost and Return Period for

a 3–5 Ton/Hour Fish Feed Plant

For clients planning to build a fish feed plant, the most critical question is always: “How much does it cost to build a 3–5 ton/hour fish feed production line?”

In reality, the investment cost for a fish feed plant is not a fixed number. It’s determined by several factors, including process configuration, capacity requirements, and automation level.

(1) Key Factors Affecting the Investment Cost of a 3–5 Ton/Hr Fish Feed Plant

① Pelleting Method: Dry / Wet / Twin Screw Extrusion

The type of extruder directly determines the cost of the entire production line and the product’s positioning.

A dry type extruder is suitable for conventional floating fish feed, with low investment and energy consumption.

A wet type extruder is ideal for sinking and slow-sinking fish feed, offering better stability and density control.

A twin screw extruder is used for high-end fish feed, shrimp feed, and pet food, allowing for more complex formulas. Factories focused on high quality typically choose this option.

② Level of Automation (Semi-Automatic / Standard Automatic / Fully Automatic)

A semi-automatic system requires more manual labor and has a lower investment, making it suitable for clients with a tight budget.

A standard automatic production line automates feeding, extrusion, and drying, balancing efficiency and cost. This is the most common configuration.

A fully automatic system features intelligent monitoring, automated formula management, and automatic packaging, achieving the highest capacity utilization but with a correspondingly higher investment.

③ Completeness of the Production Line Configuration

Typical elements affecting the price include:

Whether a secondary grinding system is needed (essential for producing sinking feed).

Whether a coating/spraying system is needed (essential for high-protein or high-fat feed).

The size of the dryer (a core piece of equipment that significantly impacts the cost of a fish feed line).

The more complete the configuration, the higher the investment, but the product quality will also be more stable.

(2) Typical Investment Costs for a 3–5 Ton/Hr Fish Feed Plant

Based on our experience from hundreds of projects in Southeast Asia, Africa, the Middle East, Latin America, etc.:

| Type | Investment Range (USD) | Suitable For |

| Economy | $150,000 – $300,000 | Small-to-medium factories needing to control their budget |

| Standard (Most Popular) | $300,000 – $550,000 | Clients producing stable-quality, conventional floating/sinking feed. |

| High-End (Twin-Screw / Fully Auto) | $600,000 – $1,000,000+ | Enterprises doing multi-product, high-value-added production. |

(3) Construction Period: Can Be Operational in as Little as 40 Days

The construction period for a 3–5 ton/hour fish feed production line typically has two main phases.

The first phase, lasting 40–60 days, includes equipment arrival, basic installation, connecting the entire line, electrical and control system integration, and comprehensive commissioning. The second phase, taking another 60–90 days, covers operator training, production parameter optimization, formula validation, and stabilizing full-capacity operation.

If the client needs a new factory building, the overall timeline will be longer due to the additional time required for civil design, construction, and inspection. We provide complete process designs, factory layouts, equipment foundation drawings, and installation guides early in the project to ensure the client can plan quickly and get the line operational as soon as possible.

(4) Return on Investment (ROI): Fastest Payback in 6 Months

The profitability of a 3–5 ton/hour fish feed plant is very strong, especially in countries with high demand for fish feed. Based on data from the projects we have helped build, the return on investment period is typically 6–12 months.

If local fish feed prices are higher, the payback period can be even shorter. Additionally, if you also produce high-value-added pellets like shrimp feed or pet food, the project’s overall profit margin will increase further.

Core factors influencing the speed of return include:

- Local selling price of fish feed. For example, in some countries, floating fish feed can sell for $600–$900 per ton, creating a large profit margin.

- Raw material costs. Prices for ingredients like soybean meal, corn, and fishmeal account for over 70% of the feed’s cost. If local raw materials are abundant, profitability will naturally be stronger.

- Factory automation level. Higher automation saves on labor. For factories running day and night, automation directly reduces operating costs.

- Daily operating hours. Most clients run the line for 10–16 hours/day. A 5-ton/hour line can produce 50–80 tons per day. The higher the output, the faster the return.

- Product diversity. A factory producing floating, sinking, shrimp, and marine fish feed has broader market coverage and is less affected by seasonal changes.

Example:

If a 5-ton/hour line produces an average of 60 tons of feed per day, with a net profit of $20–$50 per ton, the daily profit would be: $1,200–$3,000/day, which amounts to $36,000–$90,000 per month. At this rate, a standard fish feed line with an investment of $300,000–$500,000 can achieve a return on investment in 6–12 months.

Can’t Find Fish Feed Plant You Want?

Contact Us To Customize For You

What capacity fish feed plants have we built?

In our 30 years of building feed plant projects, RICHI has constructed numerous feed mills and pellet production plants in over 140 countries worldwide.

Why Build a Fish Feed Plant?

Building a fish feed plant means turning the growing demand from aquaculture into long-term, controllable profits for yourself.

Right now, farming scales for both freshwater and saltwater fish are expanding, and so is the need for feed. This creates a big opportunity, especially in areas that rely on imported feed. Imports can be expensive, slow to arrive, and have unstable quality.

By building a local factory, you can fill this market gap, secure local customers, and offer more competitive prices.

From an investment perspective, fish feed is a typical fast-moving consumer good with quick sales and fast returns. For a small-to-medium-sized production line, many clients can see their initial investment paid back in just 1–3 years. More importantly, once you own the factory, you have full control. You can adjust pellet density, protein levels, and whether the feed floats or sinks, allowing you to create formulas perfectly suited to the needs of local fish species. This results in feed that saves costs, improves yields, and is more popular with farmers.

Modern extrusion technology adds even more flexibility. A single fish feed production line can produce not only floating fish feed but also sinking fish feed, shrimp feed, and even pet food. This maximizes your production line’s utilization and creates more profit streams. Furthermore, in many countries, raw materials like soybean meal, corn, wheat, and fishmeal are abundant and locally available. This makes locally produced feed significantly cheaper than buying it pre-made.

Compared to other food and farming industries, the barrier to entry for a feed mill isn’t very high. The processes are standardized, automation is mature, and it’s easy to expand production. For fish farmers, traders, and agricultural investors, this is an excellent project to “move upstream” in the supply chain.

In short, stable markets, high demand, controllable profits, and plenty of room for expansion are why an increasing number of countries and investors are choosing to build fish feed plants.

How to Build a Feed Plant? What Key Points Must Be Considered Beforehand?

Building a feed plant isn’t as simple as just buying a few machines. It’s more like a systems engineering project that requires clear planning step-by-step, covering “Land—Process—Equipment—Personnel—Operation.”

A

define your goal

B

site selection and factory design

C

equipment selection

D

consider infrastructure in advance

E

management

First, you need to define your goal: What kind of feed will you produce?

Floating fish feed, sinking fish feed, shrimp feed, or do you plan to expand into pet food in the future? The product type determines the process, the equipment you buy, and how the factory is laid out.

Next comes site selection and factory design.

The site needs to be large enough with convenient transportation for raw materials to enter and finished products to exit. A rational factory layout is crucial; otherwise, issues like dust cross-contamination, inefficient logistics, and difficult equipment maintenance will constantly reduce efficiency. Then there’s the process design—this step is critical. A mature production line, from raw material receiving, grinding, mixing, pelleting/extrusion, drying, coating, cooling & sieving, to packaging, must be matched to your output targets and budget at every stage.

The third key point is equipment selection.

More expensive doesn’t always mean better; the equipment should match your market and expectations. If your budget is limited, you can start with an economy-level configuration. But if you need to consistently produce 3–5 tons per hour, you must choose durable, easy-to-maintain core equipment, especially the grinder, extruder, and dryer, as these three have the biggest impact on output and pellet quality.

In addition, you must consider infrastructure in advance.

Such as power, water, steam (if using wet extrusion or conditioning), ventilation/dust collection, and storage space. If these supporting facilities are not planned well, later modification costs will be very high.

Finally, there’s staffing, operator training, quality control systems, and post-commissioning operations management.

All of which will determine whether the factory can run smoothly and efficiently in the future.

Other Fish Feed Production Line Capacities

We have compiled fish feed production line solutions with different capacities below. If there is a configuration that matches your needs, you can click to view the details directly. If no suitable option is available, feel free to click the “Customize” button and fill in your requirements. Our team will contact you as soon as possible.

Why Choose RICHI to Help You Build Your Fish Feed Plant?

As a leading manufacturer of feed production equipment, RICHI provides high-quality machinery and professional services for the agriculture and aquaculture industries. Since our founding in 1995, we have continuously innovated and updated our feed equipment to stay ahead of the times. With advanced processing technology, superb craftsmanship, and strict quality inspection systems, we strive to provide our customers with excellent products.

30

RICHI Machinery

has been around for 30 years

We can offer clients turnkey projects for 1-100 ton/hour general feed plants and 1-50 ton/hour fish feed plants. Our comprehensive service includes factory layout design, manufacturing of the complete set of equipment, on-site installation, and staff training. Choosing the right partner can help you start your aquatic pellet feed production business more smoothly.

300+

We have helped build hundreds of

fish/shrimp feed

production lines from scratch.

International Certification

All our equipment has passed ISO9001:2008, CE,

CU-TR

and other certifications.

140+

Our feed pelletizing equipment has been sold to

more than 140 of the

more than 200 countries and regions in the world

1000+

We now offer our

related services to so many feed

producers worldwide.

CUSTOMER VISIT

We warmly welcome every customer who comes from afar. Face-to-face talks bring us closer as partners and build stronger trust.