3 t/h Fish & Shrimp Feed and 1t/h Chicken & Duck Feed Factory in Malaysia

Multifunctional Feed Factory For Fish, Shrimp & Poultry (Customized Design)

Production feed for tilapia, catfish, grouper, shrimp, as well as chicken and duck

Feed Specifications:

1-8 mm fish/shrimp feed & 1-5 mm chicken/duck feed

Raw Materials:

Fish meal, soybean meal, palm kernel meal, tapioca flour, shrimp shell meal, rice bran, palm oil, corn, wheat, premix…

Production Capacity:

1-3 tons/hour

Type:

Fish/Shrimp Feed & Chicken/Duck Feed Factory

MALAYSIA AQUACULTURE MARKET

Malaysia’s aquaculture is rapidly advancing, with growing demand for aquatic feed as farming capacity rises. Shrimp, tilapia, and bass are key farmed species, driving market expansion. Aquatic feed makes up about 25% of the compound feed market, with increasing segmentation—extruded pellets for freshwater fish like tilapia and catfish, and specialized formulas for premium shrimp.

Yet, challenges persist, especially in feed.

Intensive farming risks water quality and disease, requiring high-quality feed. Costs fluctuate with fishmeal and fish oil prices, and scattered small-scale farmers complicate supply, nutrition, and quality control.

Looking ahead, large-scale, modernized aquaculture will boost feed demand.

High-performance, eco-friendly feed—using plant proteins to replace some fishmeal—will dominate, balancing cost and sustainability. Multifunctional feed lines and smart equipment enable easy switching between feed types, enhancing efficiency and convenience.

CLIENT PROJECT DETAILS

The client for this project is an emerging feed company in Malaysia. Initially, they planned to build a factory focusing on aquatic feed, mainly serving tilapia, catfish, grouper, and shrimp farmers. Preliminary research showed that there was a shortage of high-quality aquatic feed locally, so the client decided to invest in a fish and shrimp feed production line with a capacity of 3 tons per hour.

Although aquatic feed was their core business, Malaysia’s poultry farming industry (especially broiler chickens and egg-laying ducks) was also large, with a strong demand for cost-effective, nutritionally balanced pelleted feed. Our engineers promptly suggested that, based on the same core pelletizing system, we could use modular design to flexibly produce 1-5mm chicken and duck feed without needing additional separate production lines.

Our sales manager also shared successful cases of multifunctional production lines we had delivered in Southeast Asia and other regions (such as Uzbekistan and Argentina), showing the client practical results.

After comprehensive evaluation of return on investment, market potential, and equipment flexibility, the client ultimately adopted our suggestion. They added a dedicated set of poultry feed pelletizing equipment to their original aquatic feed production line, forming a composite, multifunctional feed production line.

This multifunctional feed production line can meet both aquatic and poultry feed production needs: aquatic feed pellets range from 1-8mm, available in sinking or floating types, suitable for tilapia, catfish, grouper, and shrimp; poultry feed pellets are 1-5mm, designed with high density to meet the nutritional requirements of broiler chickens and egg-laying ducks at different growth stages.

Project Highlights:

One Factory, Dual Use, More Cost-Effective Investment

Quick Switch, Market-Responsive Flexibility

Significant Local Advantage

Future Expansion Potential

CUSTOM-TAILORED SOLUTION

No two clients have exactly the same aquaculture feed production needs. In the aquaculture industry, different aquaculture species and fish growth stages have different requirements for feed pellet size and nutritional composition.

RICHI always puts the real needs of customers first. Before providing a feed production solution, our engineers conducted a detailed consultation with the client:

Besides tilapia, catfish, grouper, and shrimp, do you have plans to produce other aquatic species?

Are there any special requirements for poultry feed pellet density, size, or formula (e.g., 1–5mm, high-density, etc.)?

What raw materials are you mainly planning to use? Do you have a preference for localized ingredients, such as making full use of palm by-products or local grains?

Are there any specific restrictions on the factory’s land area, energy consumption, or equipment layout?

Based on this information, we design a more tailored solution for the client, ensuring that aquatic feed pellet and poultry feed pellet equipment configuration and process design are fully aligned with clients’ specific needs, helping them resolve operational challenges.

As requested by this customer from Malaysia, the equipment configuration of this 3 ton/hour fish/shrimp feed factory and 1 ton/hour chicken/duck feed factory is very complete.

The final fish and shrimp feed mill includes the following sections:

Pre-processing System

Raw materials are received, cleaned, de-contaminated, and pre-sorted to ensure they enter the next stage free of impurities, metal contaminants, or clumps.

The system is equipped with magnetic separators, vibrating screens, and temporary storage bins, enabling simultaneous handling of multiple ingredients.

01

Crushing System

High-efficiency hammer mills grind coarse materials into the desired fineness, while a pulse-dust removal device controls dust emissions for eco-friendly and safe operation.

02

Mixing System

Main ingredients, additives, and premixes (e.g., vitamins, minerals, enzymes) are thoroughly blended here. Batch accuracy is tightly controlled, and formula switches can be completed rapidly.

03

Extrusion System

The core process uses a twin-screw extruder for aquatic feed, applying high temperature, pressure, and shear forces to cook, gelatinize, and shape the material.

A quick-change die head allows fast adjustment of pellet specifications.

04

Drying System

Hot air gently and uniformly dries the extruded moist pellets, preventing cracking or nutrient loss.

Zone-controlled temperature and airflow ensure energy efficiency while meeting low-moisture storage standards for aquatic feed.

05

Spraying System

Oils, antioxidants, or flavorings are evenly sprayed onto dried pellets to boost energy density, palatability, and stability.

Metering pumps and atomizing nozzles deliver precise, waste-minimized coating.

06

Cooling System

Pellets are rapidly cooled to near-ambient temperature to prevent oil oxidation, mold, or breakage.

Cooling duration and air volume are adjustable.

07

Packaging System

Fully automated packaging integrates weighing, sewing, and palletizing. Supports standard bags (25kg, 40kg) or ton bags.

Includes electronic scales, auto-sewing machines, metal detectors, and coding devices to ensure traceability, contamination prevention, and compliance with Malaysian feed labeling regulations.

08

To produce chicken and duck feed, we just added a channel beside the extruder—connected to the mixing system at the front and the drying system at the back. This allows for a seamless process from raw material handling, pelletizing, drying, cooling, screening, and packaging.

The chicken and duck feed factory includes the following sections:

Pre-processing System

Crushing System

Mixing System

Pelletizing System

Drying System

Cooling System

Packaging System

Pelletizing System

The mixed raw materials are heated, compressed, and shaped into pellets of different specifications.

This process determines the shape and density of the pellets, while also ensuring even distribution of nutrients.

04

malaysia FISH/shrimp FEED & chicken/duck feed factory CONFIGURATION

Since it is a multifunctional production line, no separate additional production lines need to be built for producing chicken and duck feed. In the pelletizing section, we have reserved dedicated channels and connected them to an animal feed pelletizer. When there’s a need to switch between different types of feed, this can be done simply by using a switch.

01

Pre-processing System

cylindrical primary cleaner

02

Crushing System

Hammer Mill

03

Mixing System

single shaft paddle mixer

04

Extrusion System

Twin Screw Extruder

04

Pelletizing System

animal feed pellet machine

05

Drying System

Mesh Belt Dryer

06

Spraying System

Vaccum Sprayer

07

Cooling System

Counter-flow Cooler

08

Packaging System

ton bag scale

Complete fish/shrimp feed & chicken/duck feed factory delivery process

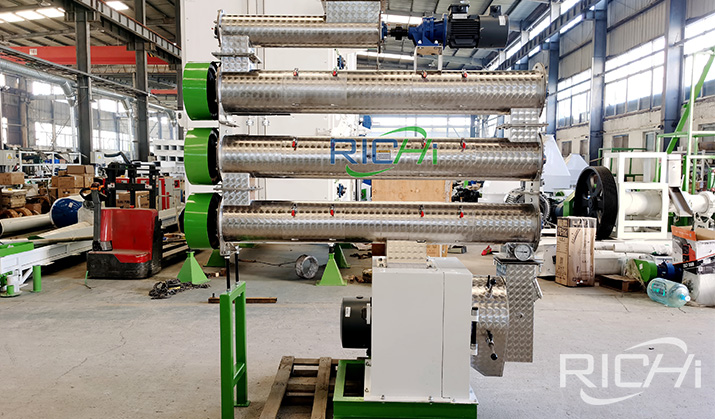

Machine Production

During production, our engineers rigorously monitor every step—from material selection to assembly and commissioning—following unified quality standards to ensure reliable performance and stable operation.

At the same time, to let customers know the progress more, we regularly capture photos and videos of the equipment manufacturing process, showcasing key equipment and semi-finished products. In this way, customers can clearly see the whole process of step-by-step molding of the whole production line even if they are not on site.

Equipment Delivery

Once all fish/shrimp feed & chicken/duck feed production equipment is fully manufactured and the necessary accessories for the multifunctional feed factory are prepared, we will arrange shipment according to the delivery schedule confirmed with you.

Whether your project is located in Malaysia or elsewhere, we can ensure the safe and timely delivery of the equipment to the project site through standardized logistics solutions and end-to-end tracking services.

Installation, Commissioning, and Training

For this project, the customers chose self-installation. To ensure a smooth installation, we provided detailed installation drawings in advance and provided online guidance. If any problems arise during installation, our technical team will timely provide solutions to get the line running smoothly.

After the feed production line is installed and commissioned, we provide clients with training, either online or on-site. This training covers equipment operation, routine maintenance, and production process management, ensuring safe and skilled use of the entire feed production line.

Customer evaluation and project operation status

Recently, our after-sales department received Malaysian client’s feedback:

Our factory runs runs like a dream. It’s stable even when running all day, with no major hiccups. Switching between aquatic and poultry feed is a breeze—simple to operate, and we barely have to stop the machine.

The whole line’s efficiency is way better than we expected. Production, drying, cooling, and packaging all flow smoothly, giving us impressive daily output. Cost control is excellent too, thanks to high raw material utilization and consistent feed quality.

Overall, we’re thrilled with how it’s performing. Not only is it easy to use, but it’s also helped us tap into both the aquaculture and poultry markets at once—delivering results that exceeded our expectations.

Types of feed suitable for production in MALAYSIA

Malaysia’s feed production has distinctive regional characteristics.

Unlike major grain-producing countries such as Argentina, Malaysia’s strengths lie in mature aquatic feed processing technology and an endless supply of internationally competitive palm oil by-products.

(1) Aquatic Feed

Malaysia is a typical strong player in aquaculture.

Fish Feed

Tilapia, Catfish, Grouper, Sea Bream

Shrimp Feed

Whiteleg Shrimp, Marine Shrimp

(2) Poultry Feed

Malaysia’s consumption of poultry meat and eggs relies heavily on domestic production, making poultry feed a massive basic industry in the country.

Chicken Feed

Duck Feed

(3) Pet Feed

Most pet food products from Malaysia target the mid-to-high-end market, emphasizing selling points like “natural formula,” “grain-free formula,” “functional nutrition,” and “Halal certification.” This makes Malaysia highly suitable as a destination for high-quality, differentiated pet brands seeking production and R&D partners.

Dry Dog/Cat Food

Small Pet Feed (Rabbits, Hamsters)

OUR PROJECTS IN OTHER COUNTRIES

For 30 years, RICHI has specialized in fish feed production machinery, driven by tech and backed by service. We create flexible solutions deployed successfully worldwide – from Russia, Ukraine through Central Asia ( Uzbekistan, Azerbaijan) to Algeria, Iran, India, Ecuador, the Philippines – adapting to various climates, ingredients, and aquaculture requirements.

1-2 tons/hour fish feed processing plant in Azerbaijan

RICHI Guarantee

In the field of aquatic feed pelletizing equipment and full aquatic feed pellet production lines, we leverage our team’s extensive experience to accurately understand your process engineering needs, deeply solve practical challenges, and tailor-made reliable solutions that meet international high standards for you.

Custom Design

Extensive Experience

Professional Service Team

Competitive Advantage

WHAT FEED PROCESSING SOLUTIONS CAN WE PROVIDE?

We can design and build complete feed pellet production lines and turnkey feed pellet machines with capacities from 1 to 100 tons per hour for all types of aquatic organisms and animals.

Fish, shrimp, crab…

Poultry & Livestock feed production line

Chicken, duck, goose, pigeon, pig…

ruminant feed production line

Cattle, sheep, horses, deer, camels…

Multi-functional feed production line

Flexible switching between multiple categories