5 Ton-Per-Hour Fish Feed Mill in Uzbekistan

Fish Feed Production Line (Turnkey Project)

Production of freshwater fish feed

Feed Specifications:

2-6 mm

Raw Materials:

Vegetable oil meal represented by cottonseed meal; and grains (corn, wheat, etc.) and their processing by-products (bran)

Production Capacity:

5 tons/hour

Type:

Fish Feed Mill

Uzbekistan AQUACULTURE MARKET

As a typical landlocked country, Uzbekistan’s aquaculture mainly relies on fresh water resources such as rivers and lakes. In recent years, aquaculture has developed very well because of the progress of science and technology and the support of the government. The scale and output of aquaculture have been increasing, so the demand for aquatic feed has been increasing.

At present, Uzbekistan can produce very few professional aquatic feeds, especially those high-end and efficient compound feeds.

Most of them need to be imported from Russia, China, Turkey and the European Union. As a result, the cost of feed will become higher, after all, it is necessary to count tariffs and logistics fees, and the supply is still unstable, which is easily affected by changes in the international situation and trade policies.

In order to reduce the cost and ensure the feed supply, Uzbekistan’s aquatic feed market is in a critical transition stage.

The market should shift from “dependence on imports” to “local manufacturing”. Therefore, whether it is local capital or foreign capital, it will be the main direction in the future to invest in the construction of aquatic feed processing plants here, and there are great business investment opportunities hidden in this market.

CLIENT PROJECT DETAILS

This fish feed mill project is a benchmark investment in the modernization of aquaculture in Uzbekistan. Now the Uzbek government is pushing aquaculture, but the local professional aquatic feed is simply not enough, and most of them have to be imported, and the price is not cheap. The customer sees this market opportunity and plans to invest in building a modern fish feed factory.

Customers first know our brand through a long-term cooperative partner. This partner often deals with aquatic equipment suppliers in China, and has purchased equipment from China many times before, which is especially recognized for our company’s technical strength, equipment stability and after-sales system. As soon as I heard that the customer was going to build a factory, I didn’t hesitate to recommend us.

In order to truly understand our production capacity and technical level, this customer from Uzbekistan also specially visited our factory. After seeing our modern production workshop, the processing flow of core equipment and the finished product testing line, we are full of praise for our manufacturing technology, quality control system and the professional ability of the engineering team.

After that, we talked about the technical details and discussed the cooperation scheme. Finally, the customer decided to cooperate with us and entrusted us to tailor an efficient and stable automatic fish feed production line for him.

This fish feed factory with an hourly production capacity of 5 tons for our customer is using local soybean meal, bran, rice bran and some imported core raw materials (such as fish meal) in Uzbekistan. The goal is to produce high-quality, cost-effective localized feed that reduces reliance on imports and helps seize market opportunities in the region.

The production line specializes in making fish feed pellets with diameters ranging from 0.6 mm to 6 mm. It meets nutritional needs for all stages—from fry , grown fish, to broodstock (parent fish). The feed is mainly supplied to local farmers raising common species like carp, grass carp, silver carp, bighead carp, and high-value fish such as bass and catfish.

CUSTOM-TAILORED SOLUTION

During the initial customer consultation phase, through detailed needs research and in-depth discussions, we accurately grasped the customers’ emphasis on production process automation. Based on these customer requirements, RICHI team designed and customized a fully automated freshwater fish feed mill solution, taking into account the customer’s freshwater fish feed production scale, raw material characteristics, and finished product specifications.

During the conversation, the customer clearly stated:

Automate processes to cut human errors, ensuring precision and feed quality.

Target steady production runs with uniform batch quality.

The final fish feed mill primarily includes the following parts:

Crushing System

The raw materials need to be crushed before entering the feed pellet mill. In order to meet the production requirements of fish feed pellet, the fish feed production line performs two crushing operations.

The first crushing uses hammer mill, and the second crushing uses ultrafine grinder.

01

Mixing System

Mixing is required after the first crushing. The crushed materials are mixed evenly to improve the efficiency of the second crushing.

After the second crushing and before pelleting, it is necessary to mix again. Through this mixing, vitamins, additives, premixes, etc. can be added to the raw materials.

02

Pelleting System

Because the customer is producing sinking fish feed, from economic perspective, he chose to use one sinking fish feed pelletizer.

After the mixed raw materials enter the feed pelletizer, they are modulated, pelletized and sheared to form fish feed pellets of different lengths with a size between 2-6 mm. The degree of maturation of fish feed pellets is relatively high.

03

Cooling System

The temperature of the feed pellets after pelleting is relatively high, generally between 80℃ and 90℃, and cannot be quickly cooled to room temperature. Therefore, a cooler is required to quickly cool them to room temperature so that the feed pellets can enter the next packaging stage normally.

After the feed pellets are cooled to room temperature in the cooler, their hardness increases and they are not easy to break during subsequent processing.

04

Packaging System

The customer has high requirements for automation, so fully automatic packing equipment is selected in the packing section. No manual packing processing is required throughout the process, and the entire packaging process can be controlled by operating instructions.

The fully automatic packing equipment greatly saves time and manpower, and improves the working efficiency of the entire fish feed production line.

05

Uzbekistan FISH FEED Mill CONFIGURATION

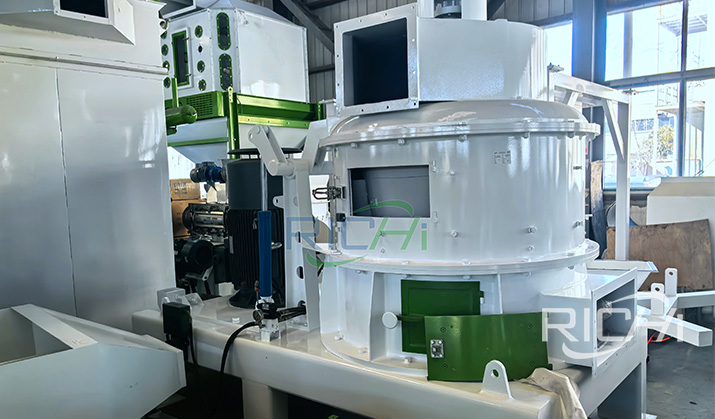

For the Uzbekistan-based 5 t/h fish feed mill project, all equipment on this mill was independently developed and manufactured by RICHI Machinery. We offer quality guarantees and lifetime after-sales service.

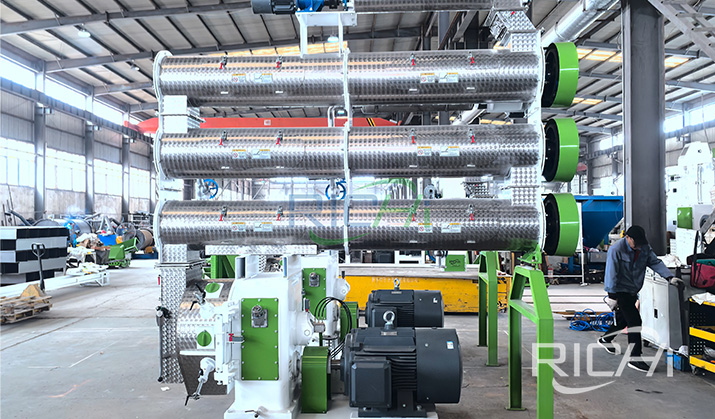

The equipment used in this project includes a hammer crusher, a ultrafine grinder, a twin shaft paddle mixer, a sinking fish feed pellet machine, a counter-flow cooler, and a ton bag scale. These fish feed making machines were custom-designed to meet the production capacity of the 5 tons/hour fish feed mill.

01

Crushing System

Hammer Crusher

02

Second Crushing System

Ultrafine Grinder

02

Mixing System

Twin Shaft Paddle Mixer

03

Pelleting System

Sinking Fish Feed Pellet Machine

04

Cooling System

Counter-flow Cooler

05

Packaging System

Ton Bag Scale

Complete fish feed MILL delivery process

Machine Production

This is a customized fish feed production line, and the customer built the fish feed mill according to our design plan, so all the fish feed production equipment needed for the fish feed production line needs to be customized..

After the design plan of the fish feed production line and the construction plan of the factory were determined, the customer signed a contract with us, and then our factory manager began to make a production plan for this fish feed production line.

The production cycle of this sinking fish feed mill is 90 days, which is 3 months. During these four months, we will regularly send customers pictures and videos of the feed pellet production equipment that has been produced or some semi-finished products of the equipment, so that customers can understand the entire production process of the fish feed production equipment they purchased.

Equipment Delivery

Within 3 months, after all these fish feed production equipment on this fish feed mill is completed and the auxiliary equipment is fully prepared, we will ship the goods according to the delivery time communicated with the customer in advance.

Shipping is a very important link. We have a complete delivery process, and our equipment has been exported to more than 100 countries and regions in the world. So no matter where your project is built, we can ensure that the equipment is delivered to your project location.

Installation, Commissioning, and Training

After the goods were delivered, we sent two engineers to the site to provide installation guidance. After the installation was completed, we provided training and guidance to the staff of the fish feed mill. We have a complete installation process, installation drawings, and detailed operating specifications, so the installation process for this customer was relatively smooth.

After the installation is completed, our after-sales team will connect with the customer to communicate and solve problems related to the operation of the fish feed production line.

One year is the warranty period for the feed production equipment we sell, but we provide permanent online service for all customers. Therefore, customers can find our after-sales staff at any time to help them solve the problems encountered in the fish feed production process and provide the accessories needed for the feed production equipment on the fish feed mill.

Customer evaluation and project operation status

Six months after stable operation of this 5 t/h fish feed mill, our customer shared his evaluation:

“This wasn’t just buying equipment—it was a strategic partnership that upgraded our entire business.”

“At first, we were cautious about such a big investment. But instead of rushing to sell, your engineers spent time discussing raw materials, target product specs, even considering Uzbekistan’s power grid and climate. Their process flowcharts and factory layout plans saved us tons of prep work—and they anticipated future expansion into other animal feeds!

Honestly, we worried cross-border communication/after-sales would be tough. Yet you assigned Russian-speaking staff and created a dedicated WhatsApp tech group. During installation, your engineers were both professional and patient—not only finishing efficiently but training our local team hands-on.

This 5 T/H fully automated fish feed production line runs smoothly from grinding to packaging. What mattered most to us was feed stability in water—our edge over local competitors. Your designed sinking pellets hold shape for over 4 hours underwater, cutting nutrient loss dramatically. Local farmers report faster growth rates and healthier fish since switching to our feed. This has earned us an excellent market reputation.”

Uzbekistan Fish Feed Mill: Value

Since full operation began, this fish feed miil has fully met its designed capacity targets, with consistently stable product quality. We now reliably supply several large sturgeon and trout farms in Samarkand and the Fergana Valley. Thanks to local manufacturing (lower costs), this investment is already delivering rapid returns.

Types of feed suitable for production in Uzbekistan

Considering Uzbekistan’s unique breeding practices and demands, locally produced feeds are highly practical, varied, and well-suited to its agricultural model. They focus on two core types: freshwater fish pellets and complete animal feed mixes, aligned with the nation’s primary farmed animals.

(1)Freshwater Fish Feed

Uzbekistan focuses on freshwater aquaculture, mainly cultivating Cyprinid fish and some predatory species. Mostly uses pelleted compound feeds categorized as follows:

Bottom fish feed (carp, crucian carp…)

Submerged pellet feed with the largest demand and the most mainstream in Uzbekistan.

Filter-feeding fish feed (silver carp, bighead carp…)

Silver Carp primarily consume plankton plants; Bighead Carp target zooplankton.

Herbivorous fish feed (grass carp, bream…)

Suitable for semi-floating or slow-sinking pellets.

Carnivorous fish feed (perch, catfish, etc.)

High-protein sinking pellets seeing rapid demand growth due to rising high-value farming.

(2)Poultry Feed

The scale of poultry breeding in Uzbekistan is huge, including broilers, laying hens, ducks, geese, etc., and the feed is mainly full-price compound feed.

Broiler Feed

Made from corn, soybean meal, fish meal and premix.

Layer Feed

Divided into different stages, including brooding, early laying and peak laying.

Waterfowl Feed (Ducks and Geese)

Tolerates coarse ingredients like wheat bran, rice husk and green forage additions.

(3)Ruminant Feed

Mainly for cows, beef cattle, sheep and goats. Feed forms are diverse.

Dairy Cow Concentrate supplement

The raw materials are corn, soybean meal, cottonseed meal, bran and premix.

Beef Feed

High-starch, moderate-protein formula for rapid weight gain.

Sheep/goat concentrated feed

Offered as pellets or mineral blocks; supplements protein/minerals during winter or poor grazing seasons.

(4)Swine Feed

Swine farming is also common in Uzbekistan, and the demand for feed is stable.

Starter Feed

Crushed or granular materials

Grower-Finisher Feed

Pelleted feed

Sow Feed

Phased nutrition

(5)Specialty Feeds

With the diversification of aquaculture, the demand for special feed is gradually emerging.

Shrimp feed

Like Penaeus vannamei, extruded floating pellets are used.

Rabbit feed

High fiber and low protein pellets

Pet feed

Small but growing market driven by urbanization trends.

OUR PROJECTS IN OTHER COUNTRIES

The 5 ton/hour fish feed mill project in Uzbekistan has been running smoothly. This case of stable operation is the embodiment of RICH’s strength in the field of aquatic feed equipment for many years. All along, we have been focusing on the research and development of aquatic feed production equipment and the whole aquatic feed production line delivery, and our business map has covered many markets around the world, including Russia, Kyrgyzstan, Kazakhstan, Azerbaijan, Bangladesh, Iran, India, Nigeria, and other countries and regions. With our reliable equipment quality and comprehensive service, we’ve earned long-term trust from global customers.

If you are planning a fish feed production line or a fish feed mill project, choose RICHI as your trusted partner. We will tailor professional fish feed production equipment solutions and full-process technical assistance to help you launch operations quickly and achieve steady profits.

2.5 Tons/Hour Fish Feed Production Line In Kyrgyzstan

This project successfully overcame the specific requirements of feed extrusion technology in high-altitude regions, providing a cost-effective, localized feed solution for salmon and trout farming. It can make good use of local common corn and soybean meal, as well as local protein ingredients like flaxseed meal. By precisely controlling conditioning temperature and pelleting parameters, it produces feed pellets for sinking fish such as grass carp and rainbow trout.

3-5 tons/hour fish feed factory in Kazakhstan

Designed by RICHI, this 3–5 tons/hour fish feed production line features a twin-screw extruder and multiple grading screens. The biggest highlight is that the production capacity can be flexibly switched according to the market demand—running at full capacity of 5 tons/hour during peak season and dropping to 3 tons/hour during off-season. This not only saves energy but also reduces costs. This line can produce feed for both coldwater and freshwater fish.

5 tons/hour fish feed production line in Russia

This production line, which is built by our company and can produce floating feed pellets and sinking fish feed pellets, adopts advanced twin screw extrusion technology, and the produced feed pellets also have super water stability, which can be kept in water for 12 hours. This production line has made remarkable achievements since it was put into production.

1-2 tons/hour fish feed processing plant in Azerbaijan

Tailored to the aquaculture demands along the Caspian Sea, this production line allows for easy switching between sturgeon feed and conventional fish feed. Considering the high sand content of some raw materials in Azerbaijan, we’ve also added an impurity removal device to the line, significantly reducing wear and and enhancing machinery durability.

1 ton/hour Shrimp Feed Plant in Bangladesh

Bangladesh is a major shrimp exporter in South Asia, and the requirements for the pellet uniformity and water resistance stability of shrimp feed are strict. RICHI designed a 1 ton/hour shrimp feed plant for a local customer. This plant adopted ultra-fine grinding technology and a double-layer conditioner to ensure uniform nutrition in feed pellets and long water resistance, and to avoid the shrimp pond from being polluted by feed collapse when shrimps eat.

2 tons/hour fish feed processing Plant in Nigeria

This fish feed processing plant features strong raw material adaptability and weather resistance, effectively tackling West Africa’s climatic challenges. It can make efficient use of cassava flour, palm kernel meal and other raw materials commonly used locally to produce high-quality feed that meets the needs of main varieties such as tilapia.

RICHI Guarantee

RICHI Machinery began as a professional manufacturer in feed pellet machine, and has now developed into a comprehensive solution partner for both feed pellet equipment and complete pellet plant systems. We take great pride in our team’s expertise and skills—from technical sales to process design engineers, every member is committed to supporting our customers. You can confidently choose RICHI to elevate your business.

In the field of aquatic feed pelletizing equipment and full aquatic feed pellet production lines, we leverage our team’s extensive experience to accurately understand your process engineering needs, deeply solve practical challenges, and tailor-made reliable solutions that meet international high standards for you.

Custom Design

Every customer’s production needs are unique, so we offer full custom design services. From production capacity and raw material type to product specifications, each production line is tailored to the customer’s actual conditions, ensuring efficient layout, optimized performance, and flexibility for future expansion.

Extensive Experience

Founded in 2013, our company has years of experience in the feed machinery industry. Whether it’s a stand-alone feed production machine or a turnkey feed production project, we can provide the perfect feed production solution.

Professional Service Team

From early consultation to solution design, equipment production, and after-sales service, we have a highly comprehensive and professional team whose members are fully committed to completing the project.

Competitive Advantage

We have a production facility covering over 60,000 square meters, and customers can visit our factory at any time. Our equipment has been exported to over 140 countries and regions worldwide, with very high customer satisfaction.

WHAT FEED PROCESSING SOLUTIONS CAN WE PROVIDE?

We can design and build complete feed pellet production lines and turnkey feed pellet machines with capacities from 1 to 100 tons per hour for all types of aquatic organisms and animals.

Fish, shrimp, crab, shellfish and other conventional aquaculture species and special aquatic animals

Cats, dogs, hamsters, turtles…

Poultry & Livestock feed production line

Chicken, duck, goose, pigeon, pig…

ruminant feed production line

Cattle, sheep, horses, deer, camels…

Multi-functional feed production line

Flexible switching between multiple categories