0.5 T/H FISH FEED PELLET LINE

Customized 0.5 ton per hour fish feed factory turnkey project for sale, including fish feed factory process design, fish feed production plan design, and a full set of fish feed production equipment.

What is A 0.5 t/h fish feed pellet line?

A 0.5 t/h fish feed pellet line combines cost-effective investment, simple operation, and stable production. It’s a popular choice for many customers entering the aquatic feed processing industry and often serves as a foundational setup for future expansion.

A 0.5 ton/hour fish feed pellet line refers to

a complete system that can steadily produce about 500 kilograms of fish feed pellets per hour.

It’s not just a single pellet machine, but an integrated production line that includes raw material handling, grinding, mixing, pelletizing/extrusion, drying, cooling, sieving, and packaging — all working together to continuously convert powdered ingredients into finished fish feed pellets.

Typically designed for small to medium-sized fish feed plants, farming enterprises producing their own feed, or start-up aquatic feed projects, this capacity offers practical flexibility. The line can produce sinking, semi-sinking, or floating feed depending on the process configuration, and supports various formulas suitable for different fish species, small batches, or multiple pellet sizes.

Production capacity

(tons/hour)

0.5

Pellet size

(mm)

0.5-12

What are its features?

Moderate output – just enough for needs

With a capacity of about 500 kg per hour, it meets daily production demands for small to medium-sized fish farms or feed mills, without the high investment and energy costs associated with larger equipment—ideal for startups or self-use projects.

Complete production line, not just one machine

Includes all stages from raw material handling to packaging, enabling continuous and integrated processing from input to finished feed pellets.

Produces various types of fish feed

Depending on configuration, it can make sinking, semi-sinking, or floating feed, suitable for different fish species, growth stages, and farming methods.

Flexible in formulas and product switching

Works well with common ingredients like fish meal, soybean meal, corn, broken rice, and rice bran. Great for multi-variety, small-batch, or multiple-size production.

Controlled investment, lower risk

Compared to higher-capacity lines, this scale requires less capital, space, and labor—perfect for entrepreneurial ventures or first-time entrants into aquatic feed processing.

Easy to upgrade and expand later

The clear structure allows room for future expansion. By replacing the main unit or adding components, capacity can be gradually increased, making it a solid foundation for growth.

What Can a 0.5 T/H Fish Feed Pellet line Produce?

A 0.5 ton/hour fish feed pellet line falls into the small-capacity range and can accommodate the production of various types of aquatic feeds and some pet foods. Depending on the process configuration, it can stably produce the following common feed types:

Floating Fish Feed

Floating pellets are currently the fastest-growing market segment. Using advanced extrusion technology, high-fat fish feed pellets can be produced, which stay suspended in water for longer periods.

Target species: Tilapia, carp, catfish, ornamental fish, etc.

Pelletizer type: Extruders (dry type extruder, wet type extruder, twin screw extruder)

Sinking Fish Feed

Conventional sinking fish feed is usually produced using pelletizing technology. However, with advancements in feed production technology, fish feed plants now also use extrusion to produce sinking fish feed, overcoming the shortcomings of traditional pelletized sinking feed.

Target species: Sturgeon, grouper, marine fish, shrimp

Pelletizer type: Pellet mill, extruder

Slow-Sinking Feed

There is also considerable market demand for slow-sinking fish feed, which consists of pellets that fall between floating and sinking types, suitable for mid-to-bottom-feeding species.

Target species: Catfish, yellow catfish, snakehead fish, seabass, turbot

Pelletizer type: Single/Twin screw extruder

Custom Aquatic & Pet Feeds

A 3–5 ton/hour fish feed plant isn’t limited to just fish feed; it’s a versatile production line capable of handling fish feed, shrimp feed, and even pet food.

Types: Shrimp, crab feed, specialty aquatic feed, mid-to-high-end pet food

Pelletizer type: Extruders, often twin screw extruders

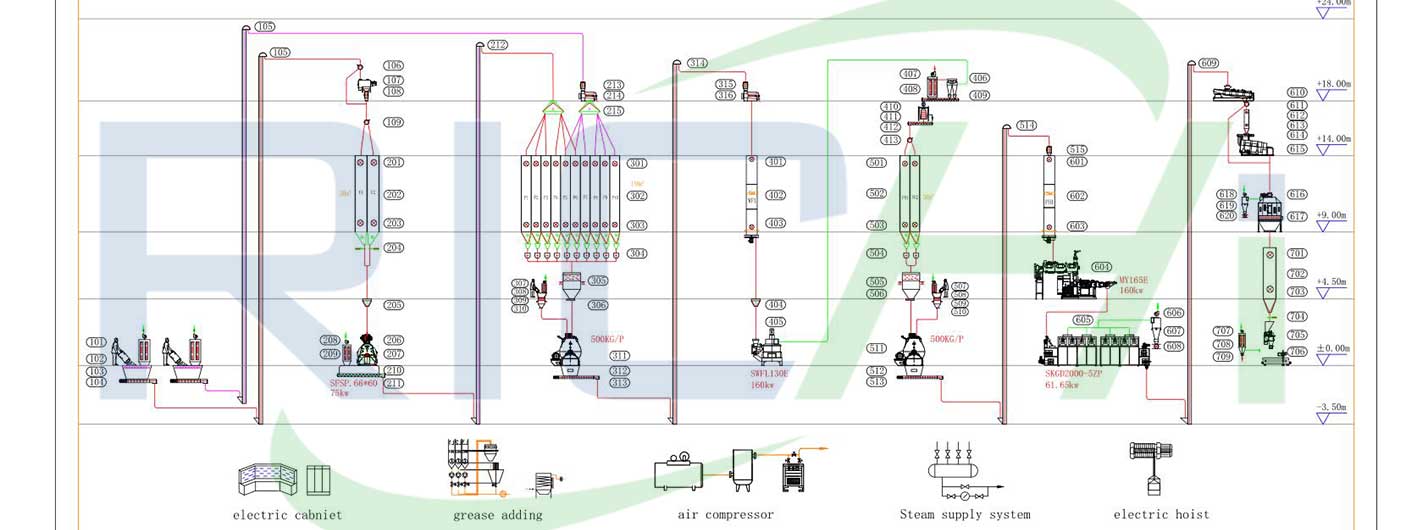

composition of A 0.5 t/h fish feed pellet line

A 0.5-ton/hour fish feed pellet line consists of several basic sections, each with a clear function — from raw material input to finished product packaging.

With years of experience in building fish feed plants, RICHI has successfully created hundreds of proven fish feed production solutions for clients worldwide.

Here is the typical production process we designed for a 0.5 t/h fish feed pellet line:

●

Raw material processing

Raw materials first undergo cleaning, impurity removal, and weighing. This ensures that the materials entering the production line are clean, consistent, and free of contaminants, laying a solid foundation for subsequent grinding and formula control.

●

Crushing of raw materials

A grinder processes materials like corn, soybean meal, and fishmeal down to the required fineness. The more uniform the grind, the better the stability of the feed’s floatability, binding properties, and digestibility.

●

Automatic batching and mixing

All ingredients are thoroughly mixed according to the formula ratio. This critical step ensures every batch has uniform nutrition and no separation, guaranteeing feed quality.

●

Pelleting/Extrusion

Pellet formation takes place in a pellet mill or an extruder. An extruder can also control the expansion level, density, and floating/sinking properties, which determine the final quality of the product.

●

Drying

Freshly made wet pellets are quickly and evenly dried to reduce their moisture content to a safe level, preventing mold and extending shelf life.

●

Spraying

Sensitive nutrients like fats, probiotics, and attractants are added evenly at low temperatures. This enhances the energy value, palatability, and market appeal of the product.

●

Cooling & Screening

Hot pellets are cooled to set their shape. At the same time, powder and broken pellets are sifted out, ensuring the finished pellets have a uniform size, a cleaner appearance, and greater stability for packaging.

●

Packaging

The line automatically weighs, bags (typically in 50kg or larger sizes), and seals the final products, creating packaged feed ready for sale.

Main equipment used in A 0.5 t/h

fish feed pellet line

As an enterprise specializing in fish/shrimp feed equipment manufacturing, RICHI has mature experience in configuring small and medium-sized feed production lines.

In this 0.5 ton/hour fish feed production line, various types of equipment have clear divisions of labor and work together to ensure raw materials are stably processed into qualified feed pellets.

Combining different feed types and raw material characteristics, RICHI selects and matches each piece of equipment specifically for the production line. This makes the entire line reliable, easy to operate, convenient for daily maintenance, and adaptable for future adjustments.

Hammer Mill

- Grinding fineness:0.5-20mm

- Rotational speed :2980 rpm

Ultra-fine Grinder

- Grinding fineness :80-200 mesh

- Capacity :1-10 t/h

Feed Mixer

- Effective volume :0.5-4 m3

- Mixing amount per batch :250-2000 kg/P

Fish Feed Extruder

- Capacity :starting from 0.3 t/h

- Price :$ 8,000

Fish Feed Pellet Machine

- Capacity :strating from 1 t/h

- Power :22-315 kw

Counter-flow Cooler

- Output :1-40 t/h

- Cooling time :6-15 minutes

Vaccum Sprayer

- Pellet Size :6-8mm

- The install period :60 Days

Belt Dryer

- Pellet Size :6-8mm

- Mesh belt width :0.8-1.6 m

Vibrating Screener

- Output: 2-50 t/h

- Screen angle :19o

Packing Scale

- Package range :10-50kg/bag ( adjustable )

- Packaging speed :2-8 packs/minute

Six Types of 0.5 T/H Feed Pellet Production Lines

Understand the needs of each project customer, serve global customers with high-endquality, and strive to create world-classfeed production solutions.

01

0.5 Ton/Hr Fish Feed Pellet Line

A basic aquatic feed production solution for small feed mills and large-scale farming users, designed to reliably turn various powders into quality fish feed pellets.

This compact, proven line includes grinding, mixing, pelletizing/extrusion, drying, and cooling. It offers a smart balance of high pellet quality, low investment cost, and stable operation, perfect for new businesses or expanding existing production.

02

0.5 Ton/Hr Floating Fish Feed Pellet Line

Designed specifically for stable floating feed production. Precise control over cooking and extrusion ensures good buoyancy and uniform appearance.

Pellets float long enough for easy feeding management and observation. Ideal for tilapia, carp, crucian carp, etc. A popular choice for small aquatic feed projects.

03

0.5 Ton/Hr Sinking Fish Feed Pellet Line

Configured for sinking feed characteristics. Focuses on controlling pellet density and structural integrity for rapid sinking and minimal disintegration.

Optimized pelletizing and processing reduce fines and improve water stability, meeting requirements for bottom/mid-water feeding fish.

04

0.5 Ton/Hr Shrimp Feed Pellet Line

Addresses shrimp feed’s higher demands for pellet strength and water stability. Features enhanced grinding precision and tailored pelletizing.

Produces uniform, dense pellets that resist dissolving, minimizing waste and fulfilling needs for high-quality sinking pellets in prawn/shrimp farming.

05

0.5 Ton/Hr Pet Food Pellet Pellet Line

Suitable for basic pet food pellets (dog/cat food). Extrusion and forming ensure thorough cooking and stable structure.

Flexible configuration, ideal for users expanding from aquafeed to pet food or conducting small-scale trials.

06

0.5 Ton/Hr Multi-functional Feed Pellet Line

Emphasizes versatility. By adjusting parameters, it can produce fish feed, shrimp feed, and some pet food pellets.

Offers greater flexibility in product switching and range compared to single-purpose lines. Perfect for users with diverse livestock/aquaculture species or those aiming to cover multiple markets, reducing redundant investments.

What are the benefits of a complete

fish feed pellet line?

Compared to using single machines or scattered equipment, a complete fish feed pellet production line offers clear advantages in production stability, feed quality, and long-term operating costs. All stages operate within one integrated process, ensuring better consistency and efficiency.

- In terms of production efficiency & stability, a complete fish feed line enables a continuous and controllable production process.

The equipment is designed for seamless connection between stages, reducing downtime and output fluctuations caused by mismatches or manual operations. This creates a smoother workflow, helping maintain a stable daily output.

- An integrated line helps maintain consistent pellet quality.

By centrally controlling grinding fineness, mixing uniformity, and pelletizing/extrusion parameters, finished feed is more consistent in key aspects like size, density, and water resistance. This reduces crumbling and waste, improving feeding results and growth performance.

- In terms of cost control, a complete production line is more advantageous for long-term operation.

It optimizes energy consumption, minimizes unnecessary reprocessing and raw material loss, and requires less labor. Compared to scattered setups, it has lower material wastage and rework rates, helping control overall production costs.

- Additionally, a complete fish feed line offers higher flexibility and scalability.

Such lines are usually designed with room for future adjustments to formulas and processes. You can flexibly change product types based on different fish species, growth stages, or market demands. If you need to expand capacity or introduce new feed varieties later, you can upgrade step-by-step on the existing foundation, avoiding redundant investments.

- More importantly, a complete line lowers overall project risk.

All equipment comes from a unified technical system, making integration mature and straightforward. Operation and maintenance are simpler, leading to a smoother project launch with fewer problems. This makes it particularly user-friendly for those new to aquatic feed production.

For these reasons, an increasing number of small-to-medium-sized feed mills and farming enterprises now prefer choosing a complete fish feed pellet production line solution when planning their fish feed projects.

Who Is the 0.5 T/H Fish Feed Pellet Line Suitable For?

The 0.5 ton/hour fish feed pellet line strikes a good balance between capacity, investment, and operational complexity, so it is not only suitable for one specific type of customer.

Commercial-scale fish farms

Local small-scale fish feed processing plants

Aquafeed startup project

Small-batch, multi-species feed producer

What capacity fish feed plants have we built?

In our 30 years of building feed plant projects, RICHI has constructed numerous feed mills and pellet production plants in over 140 countries worldwide.

Other Fish Feed Production Line Capacities

We have compiled fish feed production line solutions with different capacities below. If there is a configuration that matches your needs, you can click to view the details directly. If no suitable option is available, feel free to click the “Customize” button and fill in your requirements. Our team will contact you as soon as possible.

1-2 T/H

→

3-5 T/H

→

6-8 T/H

→

9-10 T/H

→

11-12 T/H

→

13-15 T/H

→

16-20 T/H

→

Customize

→

Why Choose RICHI to Help You Build Your Fish Feed Plant?

As a leading manufacturer of feed production equipment, RICHI provides high-quality machinery and professional services for the agriculture and aquaculture industries. Since our founding in 1995, we have continuously innovated and updated our feed equipment to stay ahead of the times. With advanced processing technology, superb craftsmanship, and strict quality inspection systems, we strive to provide our customers with excellent products.

30

RICHI Machinery

has been around for 30 years

We can offer clients turnkey projects for 1-100 ton/hour general feed plants and 1-50 ton/hour fish feed plants. Our comprehensive service includes factory layout design, manufacturing of the complete set of equipment, on-site installation, and staff training. Choosing the right partner can help you start your aquatic pellet feed production business more smoothly.

300+

We have helped build hundreds of

fish/shrimp feed

production lines from scratch.

International Certification

All our equipment has passed ISO9001:2008, CE,

CU-TR

and other certifications.

140+

Our feed pelletizing equipment has been sold to

more than 140 of the

more than 200 countries and regions in the world

1000+

We now offer our

related services to so many feed

producers worldwide.

CUSTOMER VISIT

We warmly welcome every customer who comes from afar. Face-to-face talks bring us closer as partners and build stronger trust.