500kg-per-hour floating fish feed production line in Côte d’Ivoire

Floating Fish Feed Production Line (Turnkey Project)

Production of floating fish feed pellets

Feed Specifications:

0.5-6 mm

Raw Materials:

Grains such as corn, soybeans, and wheat, as well as fishmeal, soybean meal, and rapeseed meal…

Production Capacity:

500 kg per hour

Type:

Floating Fish Feed Production Line

Côte d’Ivoire AQUACULTURE MARKET

Côte d’Ivoire’s people love fish, and the annual consumption of fishis about 500,000 tons. However, their domestic fish production is far behind consumption, and the difference depends on imports. To address this, their government has listed aquaculture as a national key industry. Recently, relying on abundant fresh water resources and warm tropical climate, the local aquaculture industry has developed rapidly. Tilapia, catfish and other varieties have been widely cultivated nationwide.

With the expansion of aquaculture, the demand for feed has also grown rapidly.

Currently, feed market mainly uses corn, cassava flour, soybean meal and fish meal as raw materials. Yet overall production capacity is limited, and the structure of feed products is single and the quality is uneven.

The key to promoting the sustainable development of Côte d’Ivoire’s aquaculture industry is to improve local feed production level.

By introducing advanced extrusion technology, establishing modern fish feed factories, not only can the fish yield and feeding efficiency be improved, but also the dependence on imported feed can be reduced. And finally enhancing Côte d’Ivoire’s aquaculture industry.

CLIENT PROJECT DETAILS

This customer runs an aquaculture farm in Côte d’Ivoire, maily raising fish and also processing and selling aquatic products.

Previously, when purchasing commercial floating fish feed, the customer have long been faced with the dilemma that feed pellets can not match their farming needs. Either the feed nutrition ratio does not meet the needs of fish growth stage, or the particle quality affects the feeding efficiency.

Based on industry research and planning for his own factory, the customer finally decided to build a floating fish feed production line.

When selecting an equipment supplier, the customer focused on the stability, energy consumption, and pellet formation of the fish feed equipment. After learning about our successful aquaculture feed production projects online, the customer contacted us, detailing their aquaculture scale, feed particle size requirements, and raw material usage plans.

After several rounds of technical discussions and proposal refinement, the customer agreed to cooperate with us and accept our design for a semi-automatic floating fish feed production line.

This floating fish feed production line can use soybean meal, barley, wheat bran, and rice bran to produce fish feed pellets with a particle size ranging from 0.5–6 mm, meeting the feeding needs of fish at different growth stages.

The landing of this fish feed production line helped the customer greatly reduce the cost of feed procurement, but also enabled him to better control the product quality, which provided strong support for the sustainable development of his aquaculture business.

CUSTOM-TAILORED SOLUTION

No two customers have exactly the same aquaculture feed production needs. In the aquaculture industry, different aquaculture species and fish growth stages have different requirements for feed pellet size and nutritional composition.

RICHI always puts the real needs of customers first. Before providing a feed production solution, we will research customers’ core pain points:

Is it difficult for purchased feed to match the breeding varieties?

Is existing production efficiency unable to support scale expansion?

What types of raw materials are available locally?

Do you have any ideas of the expected production capacity?

Based on this information, we design a more tailored solution for the customer, ensuring that aquatic feed equipment configuration and process design are fully aligned with customers’ specific needs, helping them resolve operational challenges.

As requested by this customer from Côte d’Ivoire, since he do not intend to sell the fish feed externally and will only feed their own fish, this 500kg/h floating fish feed production line does not include automatic packaging equipment.

The final fish feed production line primarily includes the following parts:

Raw Materials Receiving & Handling

Most of the raw materials purchased by this customer are powders, so they do not need to be coarsely crushed. They can go directly through the discharge pit, elevator, and then enter the powder primary screening screen for impurities, and pass through the permanent magnet to remove iron filings and other substances in the raw materials.

01

Crushing System

The fineness of the powder purchased by the customer does not meet the production requirements, so we equipped the customer with ultra-fine grinder. After the ingredients are mixed, the materials can be crushed to 60-80 meshes through the ultra-fine grinder, which fully meets the extrusion requirements of fish feed pellet.

02

Mixing System

The main equipment used in the mixing section is the mixer, which is used to mix various raw materials evenly so as to meet the production requirements of the fish feed extruder. During the mixing process, premixes, vitamins, liquids, oils and other substances required in the feed production formula are also added to the raw materials.

03

Extrusion System

Since the customer wanted to produce high-end aquatic fish feed, fish feed extruder was selected in the extrusion section.

The material undergoes a high temperature, high humidity and high pressure cooking process in the fish feed extruder to form extruded aquatic feed. The customer is very satisfied with the quality of the finished feed pellets produced.

04

Drying System

After the material is extruded by the feed extruder, it forms soft particles with a moisture content of 25%-30%. If the moisture content is too high, it needs to be dried to a moisture content below 13% (materials with a moisture content below 13% can be stored for a long time). The main equipment used in this process is belt dryer, which can achieve better drying effect for extruded feed pellets.

05

Spraying System

In order to increase the oil content in fish feed pellet, spraying equipment can be used to spray the extruded feed.

A sprayer is not a must, but the customer wants to produce high-end aquatic feed pellet that can adapt well to their own breeding needs, so the customer chooses to use spraying machine to reprocess the feed.

06

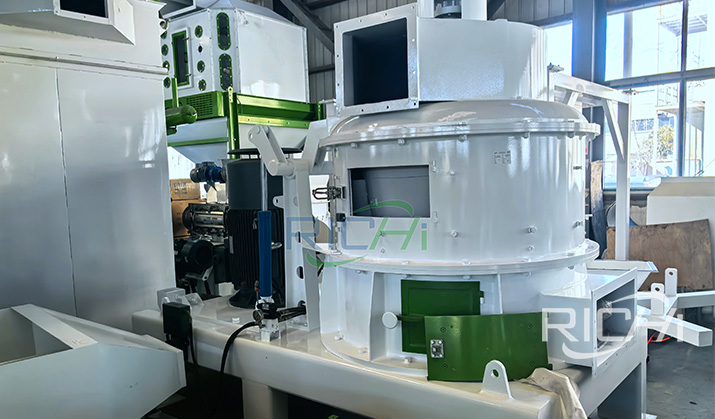

Cote d’Ivoire Floating FISH FEED PRODUCTION LINE CONFIGURATION

For the Cote d’Ivoire-based 500kg/h floating fish feed production line project, all equipment on the line was independently developed and manufactured by RICHI Machinery. We offer quality guarantees and lifetime after-sales service.

The equipment used in this project includes a cylindrical primary cleaner, an ultra-fine grinder, a single shaft paddle mixer, a floating fish feed machine, a mesh belt dryer, and a vaccum sprayer. These floating fish feed making machine were custom-designed to meet the production capacity of the line.

01

Raw Materials Receiving & Handling

cylindrical primary cleaner

02

Crushing System

Ultrafine Grinder

03

Mixing System

Single Shaft Paddle Mixer

04

Extrusion System

Floating Fish Feed Machine

04

Drying System

Mesh Belt Dryer

05

Spraying System

Vaccum Sprayer

Complete FLOATING fish feed production line delivery process

Machine Production

This floating fish feed production line is a relatively conventional aquatic feed production line, but some of the fish feed production equipment on this floating fish feed production line is specially customized according to customer needs, so production needs to be carried out after the design plan is determined.

Therefore, after the customer determined the design plan and signed a contract with us, our factory formulated a 30-day production plan to ensure that the production of all fish feed production equipment on the entire floating fish production line would be completed within one month.

During this one-month production period, we will regularly send customers pictures and videos of the fish feed pellet machine that have been produced or some semi-finished products of the fish feed production equipment, so that customers can understand the entire production process of the fish feed production equipment they purchased.

Equipment Delivery

Once all floating fish feed production equipment is fully manufactured and the necessary accessories for the floating fish feed production line are prepared, we will arrange shipment according to the delivery schedule confirmed with you.

As a long-established manufacturer in the feed equipment industry, we have a mature global delivery system. Our feed production equipment has been successfully exported to over 140 countries and regions.

Whether your project is located in Côte d’Ivoire or elsewhere, we can ensure the safe and timely delivery of the equipment to the project site through standardized logistics solutions and end-to-end tracking services.

Installation, Commissioning, and Training

After the equipment arrives at the customer’s project site, we offer flexible installation support options: You can install it yourself or have our engineers assist on-site.

For this project, the customer already had a familiar local installation team, so he chose self-installation. To ensure a smooth installation, we provided detailed installation drawings in advance and provided online guidance. If any problems arise during installation, our technical team will timely provide solutions to get the line running smoothly.

After the feed production line is installed and commissioned, we provide customers with training, either online or on-site. This training covers equipment operation, routine maintenance, and production process management, ensuring safe and skilled use of the entire feed production line.

In addition, the feed production machinery used in our designed feed production projects comes with a warranty period. After installation, our after-sales service team will proactively monitor equipment operation. Even after the warranty expires, customers can still reach out anytime for expert support, and we’ll promptly supply any needed spare parts.

Customer evaluation and project operation status

As an aquaculture farmer who’s been annoyed by feed problems for ages, I wanna share my experience working with RICHI Machinery.

“Before I built my own feed production line, none of the floating fish feeds on the market really worked for me. It wasn’t until I teamed up with RICHI Machinery that this problem was finally fixed for good.

They’re seriously reliable—from helping us design the plan at the start, to getting the equipment ready later, and even the after-sales stuff, every step was super professional. Their team talked to us a lot, asking things like how many fish we raise, what the local ingredients we use are like, and what size feed pellets we need. They ultimately customized a semi-automatic floating feed production line for us, and it’s absolutely perfect!

Now the fish feed equipment runs really smoothly, and the feed pellets it makes are nice and even. At first, we thought we’d save some trouble by having our own people install it—we were worried we couldn’t pull it off. But the technical guidance RICHI gave was so clear, and they even showed us how to do it step by step. In the end, we got the debugging done without a hitch.

Since we got this production line, we don’t have to spend a ton of money buying feed from outside anymore—costs have dropped a lot, and we can control the feed quality ourselves too.

After this experience, if I ever want to expand my scale or add more equipment, RICHI Machinery will definitely be my first choice.”

Cote d’Ivoire Floating Fish Feed Production Line: Value and Trend

This floating fish feed production line meets local aquaculture’s urgent need for high-quality feed, boosting fish yields and farming efficiency while cutting dependence on imported feed.

As farm sizes grow and markets demand more quality fish, professional, large-scale aquatic feed production will become a key trend driving the future of Côte d’Ivoire’s aquaculture industry.

Types of feed suitable for production in Cote d’Ivoire

Côte d’Ivoire is the economic core of West Africa. In recent years, its agriculture and animal husbandry have developed very rapidly. Therefore, feed production is a very promising industry there. Common feed ingredients include grains such as corn, soybeans, and wheat, as well as plant proteins such as fishmeal, soybean meal, and rapeseed meal–all widely used in poultry and livestock farming.

(1)Poultry Feed

People in Côte d’Ivoire consume a large amount of chicken and eggs, and these two are the main sources of protein for the local people. In addition, cities are developing faster and faster, and the number of middle-class people is also increasing, which has directly driven the large-scale poultry farming. As more chickens are raised, the demand for high-quality mixed feed is naturally very high.

Broiler Feed

Layer Feed

Breeder Poultry Feed

(2)Aquatic Feed

To reduce reliance on marine fishing and meet the demand for protein at the same time, the government of Côte d’Ivoire is now strongly promoting aquaculture, especially the farming of tilapia and catfish. For aquatic feed production, local raw materials such as corn, soybean meal and peanut meal can all be used. Besides, locally produced fish meal is an indispensable high-quality raw material for aquatic feed.

Tilapia Feed

Floating pellets (high demand)

Catfish Feed

Sinking pellets

(3)Ruminant Feed

The northern part of Côte d’Ivoire and its grasslands are very suitable for grazing. There are also many feed ingredients available locally, such as peanut shells, rice bran, and palm kernel cake, which can be used as ruminant feed.

Cattle Feed

Sheep Feed

OUR PROJECTS IN OTHER COUNTRIES

The 500 kg/h floating fish feed production line in Cote d’Ivoire has been running smoothly for two years locally. This case of stable operation is the embodiment of RICH’s strength in the field of aquatic feed equipment for many years. All along, we have been focusing on the research and development of aquatic feed production equipment and the whole line delivery, and our business map has covered many markets around the world, including Kyrgyzstan, Kazakhstan, Uzbekistan, Azerbaijan, Bangladesh, Iran, India, Nigeria, and other countries and regions. With our reliable equipment quality and comprehensive service, we’ve earned long-term trust from global customers.

If you are planning a fish feed production line project, choose RICHI as your trusted partner. We will tailor professional equipment solutions and full-process technical assistance to help you launch operations quickly and achieve steady profits.

2.5 Tons/Hour Fish Feed Production Line In Kyrgyzstan

This project successfully overcame the specific requirements of feed extrusion technology in high-altitude regions, providing a cost-effective, localized feed solution for salmon and trout farming. It can make good use of local common corn and soybean meal, as well as local protein ingredients like flaxseed meal. By precisely controlling conditioning temperature and pelleting parameters, it produces feed pellets for sinking fish such as grass carp and rainbow trout.

3-5 tons/hour fish feed factory in Kazakhstan

Designed by RICHI, this 3–5 tons/hour fish feed production line features a twin-screw extruder and multiple grading screens. The biggest highlight is that the production capacity can be flexibly switched according to the market demand—running at full capacity of 5 tons/hour during peak season and dropping to 3 tons/hour during off-season. This not only saves energy but also reduces costs. This line can produce feed for both coldwater and freshwater fish.

1 ton/hour floating fish feed production equipment in Uzbekistan

This production line is specifically designed based on the raw material availability in Uzbekistan, such as cottonseed meal and wheat bran, which can be easily bought locally. By adjusting the formula, the protein content of the feed is maintained within an appropriate range, meeting the nutritional needs of fish at different growth stages. has successfully filled the supply gap for high-end floating fish feed in the local market.

1-2 tons/hour fish feed processing plant in Azerbaijan

Tailored to the aquaculture demands along the Caspian Sea, this production line allows for easy switching between sturgeon feed and conventional fish feed. Considering the high sand content of some raw materials in Azerbaijan, we’ve also added an impurity removal device to the line, significantly reducing wear and and enhancing machinery durability.

1 ton/hour Shrimp Feed Plant in Bangladesh

Bangladesh is a major shrimp exporter in South Asia, and the requirements for the pellet uniformity and water resistance stability of shrimp feed are strict. RICHI designed a 1 ton/hour shrimp feed plant for a local customer. This line adopted ultra-fine grinding technology and a double-layer conditioner to ensure uniform nutrition in feed particles and long water resistance, and to avoid the shrimp pond from being polluted by feed collapse when shrimps eat.

2 Tons/hour fish feed processing Plant in Nigeria

This processing plant features strong raw material adaptability and weather resistance, effectively tackling West Africa’s climatic challenges. It can make efficient use of cassava flour, palm kernel meal and other raw materials commonly used locally to produce high-quality feed that meets the needs of main varieties such as tilapia.

RICHI Guarantee

RICHI Machinery began as a professional manufacturer in feed pellet machine, and has now developed into a comprehensive solution partner for both feed pellet equipment and complete pellet plant systems. We take great pride in our team’s expertise and skills—from technical sales to process design engineers, every member is committed to supporting our customers. You can confidently choose RICHI to elevate your business.

In the field of aquatic feed pelletizing equipment and full aquatic feed pellet production lines, we leverage our team’s extensive experience to accurately understand your process engineering needs, deeply solve practical challenges, and tailor-made reliable solutions that meet international high standards for you.

Custom Design

Every customer’s production needs are unique, so we offer full custom design services. From production capacity and raw material type to product specifications, each production line is tailored to the customer’s actual conditions, ensuring efficient layout, optimized performance, and flexibility for future expansion.

Extensive Experience

Founded in 2013, our company has years of experience in the feed machinery industry. Whether it’s a stand-alone feed production machine or a turnkey feed production project, we can provide the perfect feed production solution.

Professional Service Team

From early consultation to solution design, equipment production, and after-sales service, we have a highly comprehensive and professional team whose members are fully committed to completing the project.

Competitive Advantage

We have a production facility covering over 60,000 square meters, and customers can visit our factory at any time. Our equipment has been exported to over 140 countries and regions worldwide, with very high customer satisfaction.

WHAT FEED PROCESSING SOLUTIONS CAN WE PROVIDE?

We can design and build complete feed pellet production lines and turnkey feed pellet machines with capacities from 1 to 100 tons per hour for all types of aquatic organisms and animals.

Aquatic Feed Production Line

Fish, shrimp, crab, shellfish and other conventional aquaculture species and special aquatic animals

Pet food production line

Cats, dogs, hamsters, turtles…

Poultry & Livestock feed production line

Chicken, duck, goose, pigeon, pig…

ruminant feed production line

Cattle, sheep, horses, deer, camels…

Multi-functional feed production line

Flexible switching between multiple categories