6-8 T/H FISH FEED Production line

Customized 6-8 ton per hour fish feed production line turnkey project for sale, including fish feed factory process design, fish feed production plan design, and a full set of fish feed production equipment.

What is 6-8 t/h fish feed production line?

A 6–8 ton/hour fish feed production line is

a complete system designed for large-scale production of aquatic feed. It has a stable design capacity of 6-8 tons of pelleted feed per hour.

Primarily used in the aquaculture industry, this line processes various raw materials (such as fish meal, soybean meal, corn, wheat, vitamins, minerals, etc.) through stages like mixing, conditioning, pelletizing, cooling, sieving, and packaging. This produces high-quality pelleted feed suitable for fish consumption.

Production capacity

(tons/hour)

6-8

Pellet size

(mm)

0.5-12

What does 6–8 tons/hour capacity mean?

From a practical production perspective, 6–8 tons/hour isn’t just a theoretical number—it represents a stable, real-world output range designed for continuous, large-scale operations. conditions, fish feed pellet lines typically run 10 hours per day, non-stop.

At this pace, the line reliably produces 60–80 tons of fish feed daily—sufficient to supply multiple aquaculture farms in one region or support a feed company serving several major clients long-term.

Stable & Controllable Process

Maintains consistent pellet quality over long periods without constant manual adjustments.

Handles Raw Material Variations

More adaptable to changes in ingredient quality or formula, reducing downtime and waste.

Smooth Product Switching

Quickly transitions between different pellet sizes and floating/sinking characteristics, ideal for multi-species production.

Factory-Level Integration

Designed as part of an integrated factory system. The workflow connects smoothly, enabling efficient long-term operation and future expansion.

What Can a 6–8 T/H Fish Feed Production line Produce?

A 6–8 ton/hour fish feed plant falls into the large-capacity range and can accommodate the production of various types of aquatic feeds and some pet foods. Depending on the process configuration, it can stably produce the following common feed types:

Floating Fish Feed

Floating pellets are currently the fastest-growing market segment. Using advanced extrusion technology, high-fat fish feed pellets can be produced, which stay suspended in water for longer periods.

Target species: Tilapia, carp, catfish, ornamental fish, etc.

Pelletizer type: Extruders (dry type extruder, wet type extruder, twin screw extruder)

Sinking Fish Feed

Conventional sinking fish feed is usually produced using pelletizing technology. However, with advancements in feed production technology, fish feed plants now also use extrusion to produce sinking fish feed, overcoming the shortcomings of traditional pelletized sinking feed.

Target species: Sturgeon, grouper, marine fish, shrimp

Pelletizer type: Pellet mill, extruder

Slow-Sinking Feed

There is also considerable market demand for slow-sinking fish feed, which consists of pellets that fall between floating and sinking types, suitable for mid-to-bottom-feeding species.

Target species: Catfish, yellow catfish, snakehead fish, seabass, turbot

Pelletizer type: Single/Twin screw extruder

Custom Aquatic & Pet Feeds

A 6–8 ton/hour fish feed plant isn’t limited to just fish feed; it’s a versatile production line capable of handling fish feed, shrimp feed, and even pet food.

Types: Shrimp, crab feed, specialty aquatic feed, mid-to-high-end pet food

Pelletizer type: Extruders, often twin screw extruders

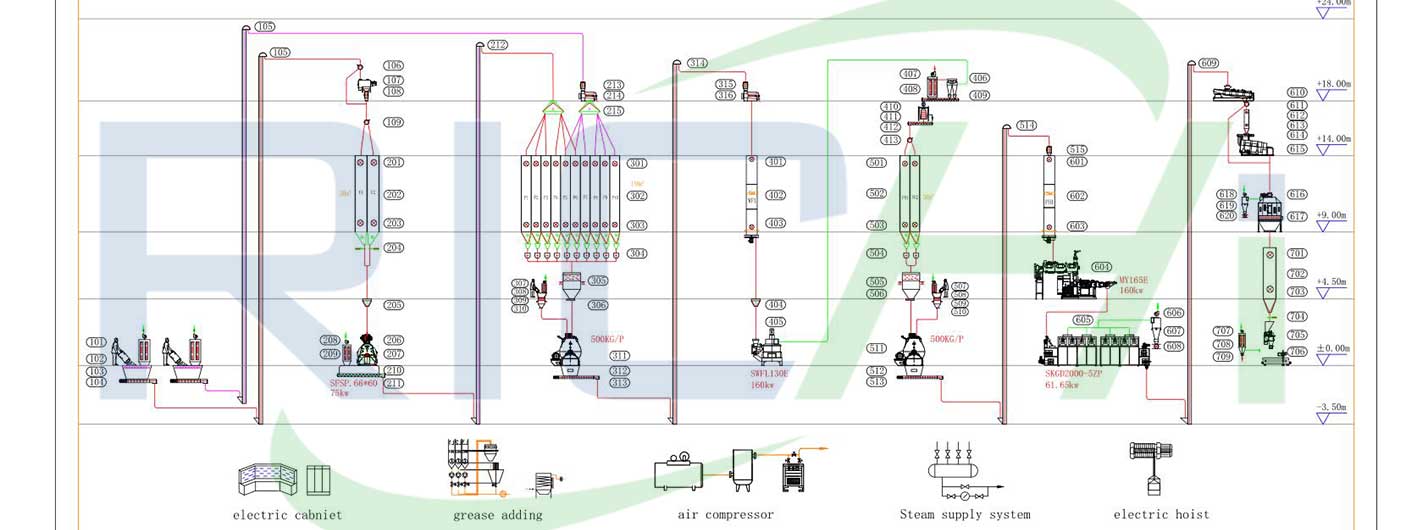

composition of A 6-8 t/h fish feed production line

To build a 6–8 ton/hour fish feed production line, beyond basic requirements like factory layout and process design, the most crucial step is selecting a stable and efficient, complete fish feed production line.

A mature fish feed production line enables automated and continuous operation from raw material reception to finished pellet packaging, thereby increasing the efficiency of fish feed pellet production.

With years of experience in building fish feed plants, RICHI has successfully created hundreds of proven fish feed production solutions for clients worldwide.

Here is the typical production process we designed for a 6-8 ton/hour fish feed production line:

●

Raw material processing

Raw materials first undergo cleaning, impurity removal, and weighing. This ensures that the materials entering the production line are clean, consistent, and free of contaminants, laying a solid foundation for subsequent grinding and formula control.

●

Crushing of raw materials

A grinder processes materials like corn, soybean meal, and fishmeal down to the required fineness. The more uniform the grind, the better the stability of the feed’s floatability, binding properties, and digestibility.

●

Automatic batching and mixing

All ingredients are thoroughly mixed according to the formula ratio. This critical step ensures every batch has uniform nutrition and no separation, guaranteeing feed quality.

●

Pelleting/Extrusion

Pellet formation takes place in a pellet mill or an extruder. An extruder can also control the expansion level, density, and floating/sinking properties, which determine the final quality of the product.

●

Drying

Freshly made wet pellets are quickly and evenly dried to reduce their moisture content to a safe level, preventing mold and extending shelf life.

●

Spraying

Sensitive nutrients like fats, probiotics, and attractants are added evenly at low temperatures. This enhances the energy value, palatability, and market appeal of the product.

●

Cooling & Screening

Hot pellets are cooled to set their shape. At the same time, powder and broken pellets are sifted out, ensuring the finished pellets have a uniform size, a cleaner appearance, and greater stability for packaging.

●

Packaging

The line automatically weighs, bags (typically in 50kg or larger sizes), and seals the final products, creating packaged feed ready for sale.

Main equipment used in A 6-8 t/h fish feed

production line

A complete feed production line requires many pieces of equipment, including main machines like grinders, mixers, extruders, and belt dryers, as well as many auxiliary devices such as conveyors, silos, and cleaning equipment.

RICHI can provide all the necessary feed production equipment, and we manufacture these machines ourselves. With a production workshop of over 60,000 square meters, modern manufacturing facilities, and a professional team, we can guarantee the quality of every piece of feed machinery.

Our factory welcomes every customer to visit at any time. We also invite you to come to our company to discuss your ideas.

6-8 T/H Fish Feed Production Line: Comparison of Pelleting vs. Extrusion Processes

The choice between these two processes should be based on a comprehensive evaluation of your product types, market positioning, investment budget, and operational costs.

Generally, if the goal is to produce standard floating or sinking feed with a limited budget, the pelleting process is the preferred option.

However, for pursuing high-protein, high-value-added feeds and achieving product diversification, the extrusion process is more suitable for long-term development.

Pelleting Process: The Conventional Method

This is a traditional and widely used method in fish feed production, typically employing a ring die fish feed pellet machine.

It is well-suited for various feed types, including sinking feed and formulas with conventional ingredients. Due to its simple equipment structure and ease of operation and maintenance, the pelleting process is ideal for medium-to-large-scale production lines seeking stable, continuous output. The resulting pellets have moderate uniformity, which meets the fundamental quality requirements of most aquaculture farms.

However, the pelleting process has limitations. Its adaptability is lower for high-protein, high-viscosity, or functional feeds. The pellet density is also relatively low, which can affect stability during long-distance transport and durability during long-term storage.

Extrusion Process: The Advanced Method

This uses high temperature and pressure to extrude and puff mixed raw materials into pellets. Common equipment includes dry and wet type extruder, as well as twin screw extruder.

The extrusion process is very flexible. It can produce floating, sinking, high-protein, or functional fish feed. The pellets have great expansion, strong water resistance, and perform well during transport and storage. This method also allows for producing premium formulas to meet high-value market needs.

However, the extrusion process requires higher equipment investment, energy consumption and operation and maintenance than granulation, and needs professional management.

6 Types of 6–8 Ton/HR Feed Production Lines for Fish, Shrimp , pet & more

6-8 Ton/Hr Fish Feed Production Line

A medium-capacity line that can stably produce floating, sinking, and various other types of aquatic feed.

It features a mature, highly adaptable process, suitable for factories with multiple formulas or those serving various farmed species.

Can be configured with single-screw, wet, or twin-screw extrusion systems to meet different density and quality requirements.

6-8 Ton/Hr Floating Fish Feed Production Line

This production line specializes in high-expansion, strongly-floating fish feed pellets, often used for markets like tilapia, grass carp, carp, and perch.

Its core equipment is an extruder, which allows for stable control of cooking level, pellet density, and expansion rate.

It’s ideal for clients looking to create brand-oriented, differentiated floating feeds.

6-8 Ton/Hr Sinking Fish Feed Production Line

Meets the production needs for conventional or premium sinking fish feed, offering a choice between a ring die pellet mill or an extruder.

Ring die is suitable for high-volume, cost-sensitive products; extrusion is better for high-protein, high-fat, and more palatable formulas.

The entire line can support the large-scale production of sinking feed for species like tilapia, catfish, blunt-snout bream, and marine fish.

6-8 Ton/Hr Shrimp Feed Production Line

Specialized in producing high-density, water-stable shrimp feed pellets (semi-floating or sinking).

The line typically includes a twin-screw extruder or a ring die pellet mill, allowing for precise control over pellet hardness, shape, and micro-level size.

It’s designed for the shrimp farming market, including species like Pacific white leg shrimp, giant freshwater prawn, and tiger shrimp.

6-8 Ton/Hr Pet Food Pellet Production Line

Used for producing pet food pellets like dog and cat food.

It comes equipped with a twin-screw extruder, a precision coating system, and controlled drying/aging processes to meet the demands for high-fat, high-palatability, and high-expansion products.

It can manufacture various types of pet food, such as complete diets, grain-free kibble, high-protein foods, and puffed snacks, making it a mainstream capacity for entering the pet food market.

6-8 Ton/Hr Multi-functional Feed Production Line

This is a hybrid production line compatible with both aquatic and livestock/poultry feed.

It’s suitable for the large-scale production of aquatic feeds (for fish, shrimp, crab) as well as common animal pellets (for chicken, duck, goose, cattle, sheep).

The line uses a modular design: the aquatic feed section can use an extruder, while the livestock/poultry section uses a ring die pellet mill. This setup allows for switching between different product lines based on orders.

What capacity fish feed pRODUCTION LINES have we built?

In our 30 years of building feed plant projects, RICHI has constructed numerous feed mills and pellet production plants in over 140 countries worldwide.

How to Plan Your 6–8 Ton/Hour Fish Feed Production Line?

The 6–8 ton/hour capacity marks a medium-to-large-scale project. The quality of your initial planning will directly impact long-term operational costs and future expansion potential.

First, define your actual production needs and operating model.

Reaching a capacity of 6–8 tons/hour doesn’t mean you must run at full output every day. You need to determine your daily production volume and whether it will be batch processing based on orders or continuous, multi-shift operation.

Additionally, clarify if the line is primarily for internal use (your own farms) or if it will also supply external customers. These decisions will influence the equipment’s model, power requirements, and overall investment budget.

Second, specify the feed types and target fish species.

The process requirements vary significantly between different fish species and feed types. You must decide whether you’ll produce floating, sinking, or slow-sinking pellets. Concurrently, identify your primary fish species—are they common varieties like tilapia and carp, or high-value species like perch and salmon? This crucial step determines whether an extrusion or pelleting process is best for your core operations.

Third, assess your raw material conditions.

Many project failures are not due to poor equipment, but to inadequate raw material evaluation. Confirm that your source of raw materials is stable and understand their typical ranges for moisture, protein, and fat content, including any seasonal variations. A well-planned production line should operate reliably even with minor fluctuations in raw material quality, rather than requiring constant shutdowns for adjustments.

Fourth, plan for future expansion.

A 6–8 ton/hour line is often a stage in a company’s growth, not its final destination. During the planning phase, consider the potential to expand to higher capacities, add new feed formulations, and upgrade automation and control systems. Planning ahead ensures that future expansion can be achieved without a complete overhaul, making the investment risk more manageable.

Finally, and most importantly, look beyond specifications and blueprints.

Refer to real-world, successfully operating projects. Case studies provide invaluable insight into whether a configuration is practical, reliable for long-term use, and can help you avoid the pitfall of a system that “looks good on paper” but underperforms in reality.

Why Choose a Pro for Your 6–8 Ton/Hour Fish Feed production Line?

Building a 6–8 ton/hour fish feed line is a big step. Go with a pro, and you get more than just machines. You get guaranteed quality, rock-solid processes, and a project that runs like clockwork from start to finish.

The best manufacturers don’t just sell equipment; they help you map out your whole production flow.

Based on your exact needs—your capacity, feed types, and raw materials—we plan everything perfectly. Every step, from cleaning and grinding ingredients to making, cooling, and packing perfect pellets, connects smoothly for maximum efficiency.

And with full support—installation, training, maintenance, and expert advice—you’ll be running at peak performance from day one. Want to expand later? Change a recipe? No problem. We’ve got you covered.

That’s the RICHI Machinery difference. We’re experts in aquatic feed, with a proven track record of successful projects worldwide. For your 6–8 ton/hour vision, we offer turnkey, custom-built solutions. We’re with you every step: designing, building, installing, training, and supporting you long after the sale. It’s all part of our one-stop-shop promise.

Choose RICHI, and you’re not just getting a fast, reliable line that makes top-tier feed. You’re setting your business up for long-term success. Our designs make it easy to grow and innovate. It’s a partnership built for the long haul, putting your aquatic feed business on the path to consistent, healthy profits.

RICHI Machinery

EXPLORE OUR OTHER Fish Feed Production Line Capacities

We have compiled fish feed production line solutions with different capacities below. If there is a configuration that matches your needs, you can click to view the details directly. If no suitable option is available, feel free to click the “Customize” button and fill in your requirements. Our team will contact you as soon as possible.