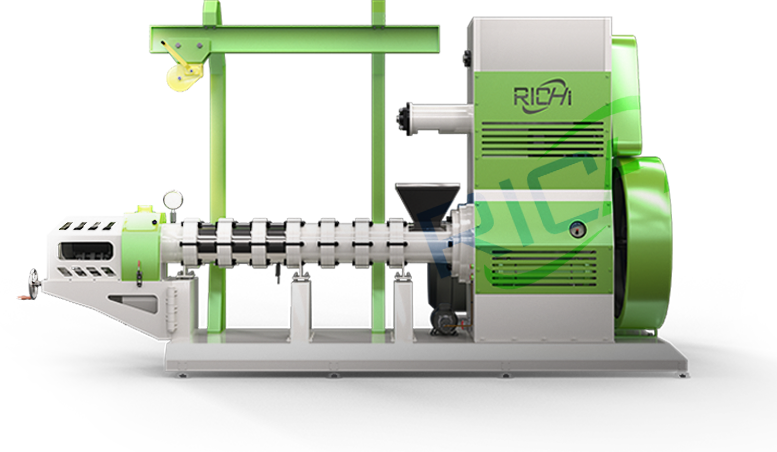

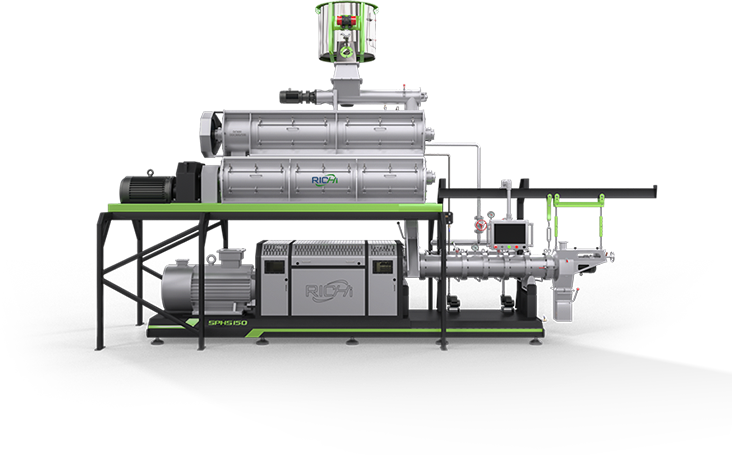

Dry Type Fish Feed Extruder

Perfect for small-scale fish/shrimp feed production— around 1,600 kg of daily feed output based on an 8-hour shift.

Solar-powered assisted dry type fish feed extruder, but requires a three-phase power supply. Low-cost, low-energy, high-performance.

Capacity

0.2 T/H +

Power

37 KW –

Dry Type Fish Feed Extruder Introduction

High feed costs, uneven quality, and purchased feed pellets that don’t suit the feeding habits of your own fish and shrimp… These are common problems for many aquatic farmers.With nearly three decades of experience in the feed machinery industry, RICHI Machinery has mature experience in the production, R&D, and sales of fish feed equipment and fish feed production solutions. Our dry type fish feed extruder is specifically designed to address these issues mentioned above. It uses high temperature and high pressure to process diverse raw materials – including corn, soybean meal, and wheat bran – into high-quality finished feed pellets. These pellets not only meet the feeding requirements of aquatic species like fish, shrimp, and crabs, but are also safe and suitable for pets like cats and dogs.

Free from complicated steam system, this compact fish feed machine offers easy controls anyone can master quickly. It produces feed: balanced nutrition, uniform in size, and easy to digest – helping animals grow faster and healthier. And its dry extrusion process means zero steam boiler requirements, reducing investment costs and running expenses. For fish farmers or fish feed mills with limited budgets and moderate production needs, the dry type fish feed pelletizer is the perfect choice.

At RICHI, we focus on developing fish feed equipment that stands the test of practical aquaculture. If you’re looking for a mature and reliable fish feed production solution to make high-quality feed suitable for fish and shrimp, try our dry type fish feed extruder — making good feed your own way.

Dry Type Fish Feed Extruder Working Principle

The dry fish feed extruder may look simple, but it’s built with everything it needs – a feeding device, screw, pressure chamber, shaping die, cutter, plus a driving and control system.

Understanding how this pellet machine works isn’t difficult.

Its main drive shaft spins the auger screw, which then compresses and pushes material forcefully between the the screw and the screw sleeve. During this process, the material’s temperature gradually rises while it is subjected to significant pressure and kneading. As a result, the starch in the raw materials to gelatinize and the protein structure to change. So the feed becomes more flavorful and easier for animals to digest.

When the materials are pushed to the die, the high-speed cutter at the front of the machine will cut the extruded material into pellets at a set angle and speed. As the pellets leave the die, the pressure suddenly decreases, causing any remaining moisture inside quickly transform into steam, making the pellets soft and porous. This expanded structure not only enhances palatability but also improves water stability—reducing waste and ensuring more feed gets eaten.

It easily handles common ingredients like corn, peanut meal, wheat bran, and fish meal, turning them into floating or sinking feed for fish, shrimp, and crabs – and it can even make tasty pet food for cats and dogs.

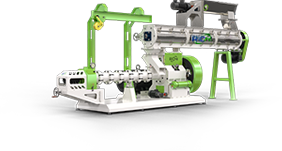

Dry Type Fish Feed Extruder Features

For decades, the dry type fish feed extruder has been one of the most popular machines in aquatic feed production. It is especially efficient for producing low-protein feeds for adult fish like tilapia, grass carp, and carp—fast, cost-effective, and widely used by feed processing businesses. Its long-standing market presence isn’t due to hype, but to practical, user-focused technology that truly meets farmers’ needs.

01

Advanced Pellet Structure

Uses international advanced pellet technology, with soft cutters to flexibly control pellet length according to actual needs.

02

Wear-Resistant Materials

Crafted from alloy steel, the screw sleeve and screw can withstand high-temperature and heavy friction, guaranteeing a long service life.

03

Easy Part Replacement

The die plate is easy to replace. If you need different hole sizes, just need to swap in the corresponding die.

04

Adjustable Feeding Speed

Equipped with a variable-speed feeder, it allows real-time adjustment of feeding rate based on raw material condition and output needs. This ensures even feeding and prevents clogging.

05

Special Configuration

The unique pressurized die design ensures each feed pellet is solidly formed with high production efficiency; the electric heating device makes the feed puff more fully, resulting in better taste and nutrition.

06

Unique Design

The overall structure design is reason, making it easy to disassemble and assemble, and convenient for daily cleaning and maintenance.

Dry Type Fish Feed Extruder Technical Specifications

| Model | Capacity (T/H) | Main Power (KW) | Feeding Power (KW) | Cutting Power (KW) | Dia. of Screw (MM) |

| DGP90-B | 0.3-0.4 | 37 | 0.75 | 0.55 | Φ90 |

| DGP120-B | 0.5-0.6 | 55 | 1.1 | 1.1 | Φ120 |

| DGP160-B | 0.8-1.0 | 90 | 3 | 1.5 | Φ160 |

Our company is expert in the manufacturing of fish feed extruders, and we offer many models for you to choose from. The table above shows the parameters of some common models of dry type fish feed extruder. If you need a machine with a different capacity, please let us know your requirements, and we will customize a solution for you.

Benefits Of Dry Type Fish Feed Extruder

What truly helps raise fish well, control costs, and increase production is the true quality and efficiency behind every pellet of feed. Dry type fish feed extruders are increasingly being chosen by fish farmers because they truly meet the practical needs of fish farms.

Dry Type Fish Feed Extruder Applications

Whether you’re raising fish and shrimp, or making cat and dog food, the RICHI’s dry type fish feed extruder is perfect for you. By simply changing the die, it can produce pellets tailored to the feeding habits of different animals. Whether it’s floating pellets that float on the water, slowly sinking pellets, or small-sized dry food that’s suitable for pets, this dry pellet-making equipment can output stably.

Suitable Raw Materials

Dry type fish feed extruder can process diverse raw materials. With the right ingredient ratios and machine settings, you can make both floating and sinking feed pellets tailored to different species’ feeding behaviors. Of course, if you have a special mix of materials, we can help you analyze if it’s suitable for dry extrusion.

corn

wheat

bean

bran

grass meal

meat and bone meal

Suitable Animals

The feed made by dry type extruders is usually hard and dense, with hard dissolution in water. It is commonly used in making fish feed. With this machine, you can adjust feed size and shape , and control whether it floats or sinks. This helps meet the eating habits of fish, shrimp, crabs and etc. Also, it can make feed for land animals. When operating, you just change the machine’s settings based on what kind of animal feed you need.

carp

tilipia

bream

catfish

giant river prawn

penaeus shrimp

dog

cat

Applicable Scenarios

The feed made by dry extruders is usually hard and dense, with low water solubility. it is commonlyused in making fish feed. The machine can adjust the size and shape of the feed, and controlwhether it floats or sinks. This helps meet the eating habits of different aquatic animals like fish,shrimp, and crabs, it can also be used to make feed for many land animals. The machine settingscan be changed based on what kind of animal feed you need.

24/7 live customer support

Clearly describe your information needs

Fish Feed Factory

Aquaculture Farms

Pet Feed Processing Plants

Angel Investors

A Complete Fish Feed Production Line

If you plan to produce your own fish feed, just using a dry type extruder is not enough. Because the extruder’s main job is only to shape the feed into pellets, it cannot complete many important steps before that.

In fact, making fish feed is a systematic and complex process. The whole process includes several steps: raw material selection, crushing, mixing, pelleting, drying, cooling, and finally packaging. Each step is important and affects both feed quality and the fish health. Only by doing each step well can you produce high-quality fish feed with balanced nutrition, easy digestion and stable quality.

Customized Fish Feed Production Line Projects

Whether you’re planning to build a new fish feed production line or upgrading your existing equipment, RICHI is able to develop a suitable, customized fish feed production solution for you. Our projects range from small-scale processing lines processing a few hundred kilograms per day to fully automated plants with outputs over ten tons per day.

You don’t need to figure out “tons per hour” yourself; just tell us what kind of feed you want to make, the raw materials you’ll use, the site size, and the approximate daily production output. Based on this, we’ll design a complete, customized fish feed production system that fits your operation perfectly.

Below are some real projects examples we’ve worked on in several countries for your reference.

Iran Fish Feed Plant

lran Fish Feed Plant

The dry type fish feed extruder used in this line has a capacity of 1 ton per hour. It is used in the customer’s small-scale fish feed factory.

Russia Floating Fish Feed Line

Russia Floating Fish Feed Line

This project uses a dry type fish feed extruder with a capacity of 0.8–1 ton per hour. It is applied in an inland fish farm.

Germany Dry Type Fish Feed Production Line

Germany Dry Type Fish Feed Production Line

The extruder used in this project has a capacity of 500 kg per hour. The same line also produces 1 ton per hour of poultry feed for the customer’s farm.

Indonesia Dry Type Fish Feed Plant

Indonesia Dry Type Fish Feed Plant

The extruder used here has a capacity of 1 ton per hour. It is used in a small fish feed factory that mainly produces fish and pet feed.

Thailand Fish Feed Processing Factory

Thailand Fish Feed Processing Factory

This 1t/h professional feed factory is mainly used to produce black tiger shrimp feed, with an annual production scale of 7,000 tons.

USA Floating Fish Feed Line

USA Floating Fish Feed Line

The dry fish feed extruder used in this line has acapacity of 1 ton per hour. lt is used in the customer’s small-scale fish feed factory

Uzbekistan Fish Feed Production Line

Uzbekistan Fish Feed Production Line

The dry type extruder used in this project has a capacity of 200–400 kg per hour. It is mainly used to produce feed for tilapia and birds.

Côte d’Ivoire Floating Fish Feed Production Line

Côte d’Ivoire Floating Fish Feed Production Line

This project uses a floating fish feed extruder with a capacity of 500 kg/h, which is mainly used to process floating fish feed pellets, and the size of finished pellets is in the range of 0.5-6 mm.

Puerto Rico Fish Feed Factory

Puerto Rico Fish Feed Factory

The fish feed extruder used in this project has an hourly production capacity of 1.2-1.5 tons, which is mainly used to process salmon and trout feed, and the particle size of the finished feed ranges from 1-6 mm.

Chile Fish Feed Production Line

Chile Fish Feed Production Line

This production line is mainly used to produce salmon feed pellets with an annual output of 3 tons. The main construction contents of the factory include high-fat extrusion system, oil immersion device and cold storage.

Why Choose RICH?

—— A Professional and Leading Manufacturer

RICHI Machinery has been deeply engaged in extrusion technology for nearly 30 years. We are committed to providing global customers with efficient and reliable fish feed extruders and complete solutions. Our focus lies in R&D and innovation for feed production equipment. By continuously refining equipment capabilities, we enable customers to boost both throughput and end-product quality.

Designed for versatility, our fish feed extrusion equipment serves multiple industries beyond aquaculture—including pet food, livestock and poultry feed. With an experienced technical team and comprehensive service support, RICHI builds intelligent and efficient feed milling solutions for customers worldwide. We are your trusted long-term partner. We offer:

Consulting and Engineering Planning

We will talk with you to get your production needs and targets, and then, our experienced engineers will take over. They will design a customized, efficient, advanced factory building solution suitable for your future development.

Project Management Support

From initial design and planning to the later equipment installation, commissioning, and after-sales maintenance, we follow up the whole process. Ensure the entire project runs smoothly and finishes on time.

One-Stop Turnkey Project

Our services for fish feed mill construction cover the entire process, from raw material input to finished product packaging. You just need to “turn the key” and start production.

Other Feed Production Equipment

We also have other feed production equipment options, each one’s designed for different uses, and they’ll help you solve specific production needs.

Our wet type fish feed extruder can turn all sorts of raw materials into soft, nutritious fish feed pellets. That way, every fish eats evenly and grows healthy.

No matter if you’re running a small, medium, or big factory, this extruder makes starting your pet food production easily.

This shrimp feed pelletizer can produce great floating or sinking pellets—so every shrimp gets its fill. Uniform size and density, precise extrusion, energy-saving.

Twin Screw Fish Feed Extruder

This twin screw extruder handles single or mixed raw materials with ease, producing feed pellets that are uniform and top-quality. It also lets you flexibly control temperature and humidity, making it easy to tackle both daily production and special formula processing.

FAQ ABOUT FISH FEED EXTRUDER

If you have any questions about fish feed extruders or feed production, you can first take a look at these answers.

1. As a farmer, I don’t know whether I should purchase a production line?

+

In fact, whether you are a farmer, an aquaculture operator, a feed processing company or a feed manufacturer, you can choose to purchase a production line. Because our production lines have many different output levels and can be adapted to different production scenarios.

So you don’t need to worry about what to do if you don’t have a suitable fish feed production line. The production line can be customized according to the production volume requirements, the size of the site, and the budget. Under suitable external conditions, we still recommend that you purchase a production line because the production line can achieve automated production and continuous processing, and can maintain the consistency of feed quality.

2. I am interested in setting up a fish feed factory in our local area. If I go to China, can I visit your factory in person?

+

Of course, we sincerely welcome you to visit our factory. We will show you around. Generally speaking, setting up a fish feed factory requires a grinder, mixer, mixer, pelletizer or extruder, sprayer, dryer, cooler, packaging machine, etc. However, please rest assured, not every type of machine here needs to be purchased. As long as you can inform us of your specific situation, we will have professionals discuss with you the actual equipment needed.

3. At your company, what capacity extruders can I buy?

+

If you’re looking for a fish feed extruder or planning to build a turnkey feed pellet plant but are not sure what size is best for you, please contact us. RICHI Machinery offers various designs in capacities from 0.5 to 10t/h and more, tailored to your budget, raw materials, final feed specifications and workshop scale.

4. If I raise many animal species and wish to build a feed production line, what should I choose in this situation?

+

You just tell us some details such as your farm/site/fishery scale, desired hourly output, acceptable power ratings, preferred feed type (for fish or pets), and packaging requirements. Based on this information, we will recommend the most suitable production line solution.

5. What benefits does using a floating fish feed extruder bring me?

+

The floating pellets made by our extruder can remain afloat for at least 12 hours; it won’t easily decompose when exposed to water. In the practical processing, the high temperature and pressure generated by fish feed machine can effectively kill harmful bacteria like Escherichia coli and Salmonella, ensuring the feed is clean, hygienic, and safe.

Meanwhile, this processing method promotes helps denature proteins and gelatinize starches, making the feed easier for fish and other animals to digest and absorb. Compared to traditional powdered or regular pelleted feeds, using expanded floating feed can also reduce consumption by 8–15% and is more cost-effective and efficient.

6. How much does it cost to buy a dry type single screw fish feed extruder?

+

Dry fish feed extruders typically range in price from 10,000 to 30,000. This model represents RICHI’s smallest and most economical feed extrusion solution.

7. I tend to prefer purchasing dry type fish feed extruders. So, what considerations should I keep in mind when selecting one?

+

Whether building a new aquafeed plant or upgrading an existing production line, choosing a right extruder comes first. You should match the extruder capacity to your overall production needs. Especially during upgrades, you should also check if your old grinders, dryers, and coolers can support the new process — to avoid equipment mismatch.

For aquafeed, good extrusion results include: pellet forming rate over 99%, powder content under 1%, uniform shape and color, and strong water resistance.

For example, floating feed should stay intact in water for at least 10 hours, and sinking feed should remain stable for more than 3 hours. This gives fish enough time to eat and reduces waste and water pollution.

8. Since there are dry type fish feed machines, are there also wet type fish feed machines? What’s the difference between them?

+

Yes, we offer both wet type fish feed extruder and dry type fish feed extruder. And the main difference lies in their processing methods.

Dry type fish feed extruder employs mechanical shearing and compression to directly transform dry raw materials into pelletized feed without adding water during processing. This method features a simpler process and lower energy consumption.

And wet type fish feed extruder requires adding controlled amounts of water to the raw materials to form a paste before extruding and shaping it. After that, it is cut into pellets. And this method is suitable for producing feeds with specific requirements for pellet density and sinking properties.