1.5-2 T/H Extruding Fish & Shrimp Feed Production Line in Iran

Fish & Shrimp Feed Production Line (Turnkey Project)

Production of fish feed, shrimp feed, floating feed and sinking feed

Feed Specifications:

1-8 mm

Raw Materials:

Fish meal, bran, rice bran, soybean cake, silkworm pupa powder, shrimp head powder and some vitamins, premixes, additives, oils

Production Capacity:

1.5 – 2 tons per hour

Type:

Fish & Shrimp Feed Production Line

IRAN AQUACULTURE MARKET

The aquaculture industry in Iran has developed rapidly in recent years. The government not only gives support, but also introduces many advanced technologies, and the demand for good quality aquatic feed is increasing. In addition, with the increase of domestic consumption and the expansion of export market, more and more trout, carp, tilapia and Penaeus vannamei are raised, and there is a great market space for floating feed and shrimp feed specially for them.

Although the aquaculture market in Iran has broad prospects, its feed production still faces many challenges.

On the one hand, water shortage and environmental pollution make the scale of aquaculture unable to expand, and the demand for feed is unstable. On the other hand, the technical level of the feed industry is not high, and both the formula research and the production process have to be improved. The produced feed is either uneven or easy to disperse in water, which cannot meet the requirements of large-scale breeding for efficient and environmentally friendly feed.

In the future, Iran is expected to gradually realize the independent supply of aquatic feed as the government continues to introduce support policies and enterprises increase their investment in localized and cost-effective feed production lines.

For example, by introducing good puffing technology, optimizing feed formula with local corn and cottonseed meal, and developing some feeds with specific functions, Iran’s aquatic feed market will certainly have a good opportunity to upgrade its technology and expand its scale.

CLIENT PROJECT DETAILS

This feed pellet production project is located in Iran and is mainly used to produce fish feed pellet and shrimp feed pellet, including both floating fish feed pellet and sinking fish feed pellets and shrimp feed pellets. This feed production line can produce 1.5-2 tons of extruded feed or 5-6 tons of sinking feed pellets per hour.

This client is a well-known aquatic product processor in Iran, mainly engaged in the processing of various fish products and the export of shrimps. Aquatic products are exported to many countries in the world, including Australia, Canada, Germany, China, etc.

At the beginning of 2022, they decided to start the business of aquatic feed production. Since they are engaged in the aquatic processing industry, they are relatively professional in the production of aquatic feed pellet. Therefore, when they are looking for aquatic feed pellet machine manufacturers, they can quickly identify the professionalism of the machinery manufacturers.

After the customer contacted us, he quickly determined that we were a professional aquatic feed pellet machine manufacturer, so after finalizing the design plan, he signed a contract with us.

The feed pellet production line is currently in operation, and the fish feed pellet it produces is not only for their own use but also sold to many aquaculture farms.

CUSTOM-TAILORED SOLUTION

This extruded fish & shrimp feed production line is a fully automatic feed pellet production line. The entire production process, from receiving and cleaning raw materials to crushing, extrusion/pelleting and packing, has a very high degree of automation, especially the packing section. The customer finally decided to use a fully automatic packing machine, which greatly saved manpower and improved the production efficiency of the feed pellet mill.

And because the customer’s site had height restrictions, we changed the design plan many times, and finally changed the aquatic feed pellet line that required a height of more than 20 meters to 8 meters.

When producing extruded aquatic feed, pellets are pelletized using feed extruder. The main production stages and processes are as follows:

Crushing System

After being cleaned by the cleaning equipment and impurities in the raw materials are removed by the impurity removal equipment, the raw materials are sent to the hammer mill through the frequency conversion feeder.

01

Mixing System

The crushed raw materials are fed into the mixer, and at the same time, premix, oil and water are added into the mixer through the small material feeding port. All raw materials in the formula are evenly mixed in the feed mixer.

02

Extrusion System

The main purpose of using aquatic feed extruder is to produce extruded feed. This customer uses the extruder to produce floating fish feed. The mixed raw materials are made into extruded pellets of different sizes through the extruder.

03

Drying System

The moisture content of the extruded feed is high, which is not easy to store and is prone to mold and deterioration, so it needs to be dried in a dryer. The moisture content of the feed after drying in the drying machine is about 11%, which can meet the requirements of long-term storage.

04

Spraying System

The dried feed is sprayed with a spraying machine. This is mainly to increase the fat content. After the surface of the feed is coated with a layer of oil, it can also improve the water resistance of the feed.

05

Cooling & Screening System

After the spraying process, the feed is first cooled in a cooler. Once it reaches room temperature, it is transferred to a screening machine.

Using multiple screen layers, this machine removes broken particles, lumps, and impurities, ultimately producing a qualified product with uniform particle size..

06

Packing System

After screening, the qualified feed pellets are packaged into 10-50 kg bagged feed by the packaging machine.

Packaged feed pellets are easier to store, use and sell.

07

When producing shrimp feed, pellets are pelletized using feed pellet machine.

When producing sinking feed pellet such as shrimp feed pellet, the process flow is: crushing section, mixing section, pelleting section, post-ripening section, cooling section, and packing section.

The production process of the equipment used in the crushing section, mixing section, cooling section, and packing section is very similar to the production process of extruded feed, but the pelleting section and post-ripening section are two sections that are different from the production of extruded feed and are needed to produce shrimp feed pellet:

Pelleting System

The equipment used to produce sinking aquatic feed pellet such as shrimp feed pellet is shrimp feed pellet machine with three-layer modulator. The mixed raw materials are modulated and pelletized in the pellet machine, and then cut into sinking feed pellets of different lengths.

03

Post-ripening System

The raw materials have been matured once in the modulator during the pelleting process. However, in order to meet the growth and development needs of aquatic organisms such as shrimp, the feed coming out of the pellet mill needs to be matured for the second time, and a maturer is needed at this time.

04

Iran FISH AND SHRIMP FEED PRODUCTION LINE CONFIGURATION

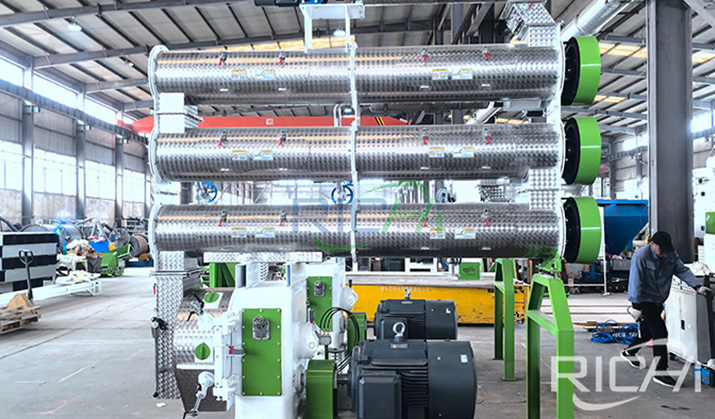

For the 1.5-2t/h extruding fish & shrimp feed production line in Iran, all equipment on this mill was independently developed and manufactured by RICHI Machinery. We offer quality guarantees and lifetime after-sales service.

The equipment used in this project includes a crusher, a mixer, a fish feed extruder machine, an animal pellet machine, a counter-current cooler, and a ton bag scale. These feed production equipment were custom-designed to meet the production capacity of the 1.5-2t/h extruding fish & shrimp feed production line.

01

Crushing System

Hammer Crusher

02

Mixing System

Single Shaft Paddle Mixer

03

Pelleting System

Fish Feed Extruder

03

Pelleting System

Shrimp Feed Pellet Machine

04

Drying System

Mesh Belt Dryer

05

Spraying System

Vaccum Sprayer

06

Cooling & Screening System

Counter-flow Cooler + Sieving Machine

07

Packing System

Packing Machine

Complete fish & SHRIMP feed production line delivery process

Machine Production

Since this fish feed pellet and shrimp feed pellet production line is completely custom designed according to customer needs, many equipment on the feed pellet line, such as feed pellet machine, spraying machine, etc. and some auxiliary equipment, need to be produced according to the design.

So after the contract was signed, our production workshop immediately developed a 60-day production plan for this project. During the two-month production process, we will regularly send customers some pictures and videos of finished or semi-finished equipment, so that customers can understand our production process from beginning to end.

Equipment Delivery

After all the feed pellet equipment is produced within 2 months, we will ship it according to the delivery time communicated with the customer in advance.

Delivery is a very important link. We have complete delivery process, and our equipment has been exported to more than 140 countries and regions in the world. So no matter where your project is built, we can ensure that the equipment is delivered to your project location.

Installation, Commissioning, and Training

After the machines were delivered, we sent two engineers to the site to provide After the goods were delivered, we sent two engineers to the site to provide installation guidance. After the installation was completed, we provided training and guidance to the staff of the feed pellet mill. We have complete installation process, installation drawings, and detailed operating specifications, so the installation process for this customer was relatively smooth.

After the fish feed and shrimp feed pellet line was installed, we arranged professional after-sales staff to communicate with customers and help them solve all problems encountered during the production process.

The warranty pThe warranty period of this fish feed and shrimp feed pellet line is one year. Within one year, no matter what problems occur with the feed production equipment, our after-sales staff will help customers actively solve them.

In addition to the one-year warranty period, we provide permanent online service, which means that in the subsequent feed production process, no matter what problems customers encounter, they can contact us at any time. In the subsequent feed production process, if customers need to replace various accessories, they can find us at any time, and all accessories are original equipment.

Customer evaluation and project operation status

After eight months of full operation at our fish and shrimp feed production line in Iran, the manager shared genuine feedback with our after-sales department:

“The feed we looked for in Iran before was either unstable in quality or too expensive. In particular, shrimp feed and high-grade trout feed are basically imported, and the cost is overwhelming us. Later, I made up my mind to build an aquatic feed processing factory to produce fish and shrimp feed myself, just to take the initiative in my own hands and not be subject to others.

The floating fish feed made from this line now has a particularly stable expansion degree and will not disperse after being soaked in water for several hours. More importantly, we can finally make high-quality shrimp feed ourselves! The feed particles produced by this fish and shrimp feed production line are not easy to go bad when soaked in water. That’s why we have a very good reputation in the farms along the Persian Gulf, and we don’t have to look at the faces of importers anymore.

Also, the environment of our workshop is not good, it is hot and dusty in summer. At first, I was worried that the equipment of this production line could not support this environment. I didn’t expect the core components of this line to be particularly durable, such as the twin-screw extruder and cutter system, which have always been very reliable and have never dropped the chain.

On the whole, this investment is worth it! It’s not just a set of equipment. With it, the core competitiveness of our company can be really raised.”

Iran fish and shrimp feed production line’s value

Building modern fish and shrimp feed mills in Iran is crucial for seizing opportunities in upgrading aquaculture. This plant offer dual benefits: using domestic crops (corn, barley) with extrusion tech creates reliable, easily digestible feed that improves farmer productivity. Plus, it eliminates import hassles and currency swings, securing steady supplies.

Types of feed suitable for production in Iran

Iran is a big agricultural country in the Middle East, with abundant land and diverse climate, which provides a unique resource advantage for feed production. In recent years, on the one hand, the government strongly supports aquaculture, on the other hand, poultry and cattle and sheep farming have also developed rapidly, and the domestic demand for feed with good effects and animals’ love has suddenly increased a lot. Moreover, Iran itself has many crops such as corn, soybeans and cottonseed meal as raw materials, coupled with advanced processing technology such as expansion technology, and is slowly building its own feed supply system.

(1)Ruminant Feed

Iran is an important cattle and sheep breeding country in the Middle East, and the demand for beef, mutton and dairy products is stable and huge.

Cattle Feed

Divided into beef cattle feed and dairy cow feed.

Sheep Feed

Sheep and goats are the main breeds in Iran.

Camel Feed

Iran has a considerable number of camels, which are used for producing milk, meat and transportation.

(2)Aquatic Feed

The Iranian government is actively promoting aquaculture to ease the pressure on wild fishery resources in the Caspian Sea and Persian Gulf. The production of aquatic feed adapted to local fish species and aquaculture conditions has broad prospects.

Expanded Floating Feed for Cold-water Fish

Suitable for trout culture in Iran (mainly concentrated in the cold waters along the Caspian Sea and in the northern mountainous areas).

Expanded Floating Feed for Warm-water Fish

For carp, tilapia and other popular consumption fish species.

Shrimp feed

Litopenaeus vannamei is the main mariculture facing the Persian Gulf coast.

(3)Poultry Feeds

Poultry industry is the most mature animal husbandry industry in Iran, and the demand for feed has been great and stable.

Broiler feed

Feed for laying hens

OUR PROJECTS IN OTHER COUNTRIES

The 1.5-2 t/h extruding fish & shrimp feed production line in Iran has been running smoothly. This case of stable operation is the embodiment of RICH’s strength in the field of aquatic feed equipment for many years. All along, we have been focusing on the research and development of aquatic feed production equipment and the whole line delivery, and our business map has covered many markets around the world, including Russia, Kyrgyzstan, Kazakhstan, Azerbaijan, Bangladesh, India, Nigeria, and other countries and regions. With our reliable equipment quality and comprehensive service, we’ve earned long-term trust from global customers.

If you are planning a fish feed production line project, choose RICHI as your trusted partner. We will tailor professional equipment solutions and full-process technical assistance to help you launch operations quickly and achieve steady profits.

2.5 Tons/Hour Fish Feed Production Line In Kyrgyzstan

This project successfully overcame the specific requirements of feed extrusion technology in high-altitude regions, providing a cost-effective, localized feed solution for salmon and trout farming. It can make good use of local common corn and soybean meal, as well as local protein ingredients like flaxseed meal. By precisely controlling conditioning temperature and pelleting parameters, it produces feed pellets for sinking fish such as grass carp and rainbow trout.

3-5 tons/hour fish feed factory in Kazakhstan

Designed by RICHI, this 3–5 tons/hour fish feed production line features a twin-screw extruder and multiple grading screens. The biggest highlight is that the production capacity can be flexibly switched according to the market demand—running at full capacity of 5 tons/hour during peak season and dropping to 3 tons/hour during off-season. This not only saves energy but also reduces costs. This line can produce feed for both coldwater and freshwater fish.

5 tons/hour fish feed production line in Russia

This production line, which is built by our company and can produce floating feed pellets and sinking fish feed pellets, adopts advanced twin screw extrusion technology, and the produced feed pellets also have super water stability, which can be kept in water for 12 hours. This production line has made remarkable achievements since it was put into production.

1-2 tons/hour fish feed processing plant in Azerbaijan

Tailored to the aquaculture demands along the Caspian Sea, this production line allows for easy switching between sturgeon feed and conventional fish feed. Considering the high sand content of some raw materials in Azerbaijan, we’ve also added an impurity removal device to the line, significantly reducing wear and and enhancing machinery durability.

1 ton/hour Shrimp Feed Plant in Bangladesh

Bangladesh is a major shrimp exporter in South Asia, and the requirements for the pellet uniformity and water resistance stability of shrimp feed are strict. RICHI designed a 1 ton/hour shrimp feed plant for a local customer. This line adopted ultra-fine grinding technology and a double-layer conditioner to ensure uniform nutrition in feed particles and long water resistance, and to avoid the shrimp pond from being polluted by feed collapse when shrimps eat.

2 tons/hour fish feed processing Plant in Nigeria

This processing plant features strong raw material adaptability and weather resistance, effectively tackling West Africa’s climatic challenges. It can make efficient use of cassava flour, palm kernel meal and other raw materials commonly used locally to produce high-quality feed that meets the needs of main varieties such as tilapia.

RICHI Guarantee

RICHI Machinery began as a professional manufacturer in feed pellet machine, and has now developed into a comprehensive solution partner for both feed pellet equipment and complete pellet plant systems. We take great pride in our team’s expertise and skills—from technical sales to process design engineers, every member is committed to supporting our customers. You can confidently choose RICHI to elevate your business.

In the field of aquatic feed pelletizing equipment and full aquatic feed pellet production lines, we leverage our team’s extensive experience to accurately understand your process engineering needs, deeply solve practical challenges, and tailor-made reliable solutions that meet international high standards for you.

Custom Design

Every customer’s production needs are unique, so we offer full custom design services. From production capacity and raw material type to product specifications, each production line is tailored to the customer’s actual conditions, ensuring efficient layout, optimized performance, and flexibility for future expansion.

Extensive Experience

Founded in 2013, our company has years of experience in the feed machinery industry. Whether it’s a stand-alone feed production machine or a turnkey feed production project, we can provide the perfect feed production solution.

Professional Service Team

From early consultation to solution design, equipment production, and after-sales service, we have a highly comprehensive and professional team whose members are fully committed to completing the project.

Competitive Advantage

We have a production facility covering over 60,000 square meters, and customers can visit our factory at any time. Our equipment has been exported to over 140 countries and regions worldwide, with very high customer satisfaction.

WHAT FEED PROCESSING SOLUTIONS CAN WE PROVIDE?

We can design and build complete feed pellet production lines and turnkey feed pellet machines with capacities from 1 to 100 tons per hour for all types of aquatic organisms and animals.

Aquatic Feed Production Line

Fish, shrimp, crab, shellfish and other conventional aquaculture species and special aquatic animals

Pet food production line

Cats, dogs, hamsters, turtles…

Poultry & Livestock feed production line

Chicken, duck, goose, pigeon, pig…

ruminant feed production line

Cattle, sheep, horses, deer, camels…

Multi-functional feed production line

Flexible switching between multiple categories