FISH FEED EXTRUDER

Want to take your fish feed quality to the next level?

Choose a high-efficiency fish feed extruder machine for uniform expansion and perfect floating performance.

Start producing high-value fish feed—right here!

FISH Feed Extruder TYPES AND TECHNICAL PARAMETERS

Currently, in aquatic feeds production, RICHI Machinery offers various extrusion equipment, including single screw extruder and twin screw extruder. And the single screw extruder can be further divided into dry type extruder and wet type extruder.

By adjusting machine parameters and using different feed formulas, aquaculture farmers and fish/shrimp feed mills can produce high-quality, nutrient-rich feed pellets to meet the diverse feeding habits of various aquatic animals.

Dry Type Single Screw Fish Feed Extruder

- Materials Properity: Dry, powdery, or granular (low moisture content)

- Feed Application: Sinking/slow-sinking fish feed & extruded pet food

- Capacity Range: Starting from 0.2 t/h (Support customization)

- Suitable for: Fish farms with low requirements for processing technology and output; small-scale feed processing factory

- Feed Quality: High expansion, good floatability

- Investment Return: Low cost, easy to use, economical

Wet Type Single Screw Fish Feed Extruder

- Materials Properity: Mixture with appropriate moisture content

- Feed Application: Floating/sinking/ slow-sinking fish feed & shrimp feed & extruded pet food

- Capacity Range: Starting from 0.5 T/H (Support customization)

- Suitable for: Medium and big sized feed mills and breeding farms

- Feed Quality: Well-cooked, dense, stable

- Investment Return: Medium cost, high quality, quick payback

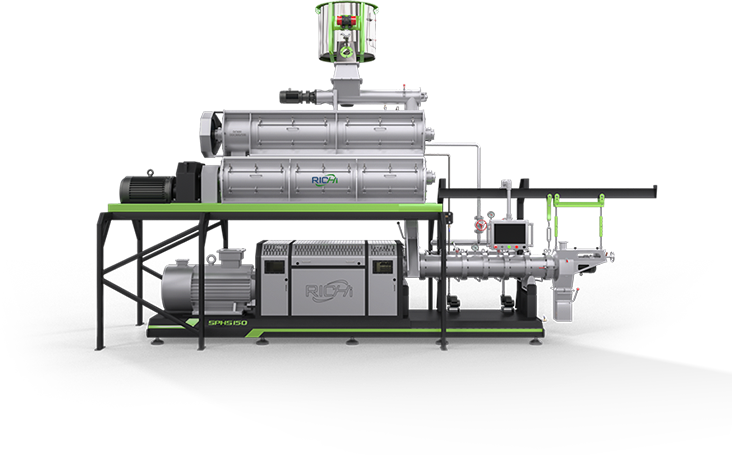

Twin Screw Fish Feed Extruder for Sale

- Materials Properity: Powder or wet materials, multiple compound ingredients, with added oils and additives

- Feed Application: Floating/sinking/ slow-sinking fish feed & sinking/slow-sinking shrimp feed & extruded pet food

- Capacity Range: Starting from 0.5T/H (Support customization)

- Suitable for: Medium and large feed mills (pursue output and long-term profits)

- Feed Quality: Uniform mixing, full expansion, best quality

- Investment Return: Higher cost, high efficiency, long-term profit

Below are the models and key parameters of several of our standard fish feed extruders to help you choose the most suitable production capacity.

| Type | Model | Main Power (kW) | Screw Diameter(mm) | Feeding power (kW) | Conditioning Power (kW) | Cutting power (kW) | Overall dimensions (mm) | Output (T/H) |

| Dry Type Extruder | DGP-90B | 37 | 90 | 0.75 | — | 0.55 | 2100×1450×1350 | 0.3–0.4 |

| DGP-120B | 55 | 120 | 2 | — | 1.1 | 2400×1950×1600 | 0.5–0.6 | |

| DGP-160B | 90 | 160 | 3 | — | 1.5 | 3100×2650×1800 | 0.8–1.0 | |

| Wet Type Extruder | DSP-90B | 37 | 90 | 7.5 | 1.1 | 1.1 | 2600×1600×1900 | 0.5–0.6 |

| DSP-135B | 75 | 135 | 7.5 | 2.2 | 1.5 | 3750×1980×1950 | 0.8-1.0 | |

| Twin Screw Extruder | SPHS75x2 | 55 | 75 | 1.5 | 7.5 | — | — | 0.5-1.0 |

| SPHS120*2 | 90 | 120 | 1.5 | 11 | — | — | 1.5-2.0 | |

| 110 | 120 | 1.5 | 11 | — | — | 3.0-4.0 | ||

| SPHS150*2 | 200 | 150 | 1.5 | 11 | — | — | 5.0-6.0 | |

| SPHS185*2 | 355 | 185 | 2.2 | 11 | — | — | 10-12 |

Fish feed extruder function

Using high temperature and pressure, fish feed extruder machine can cook raw materials into uniform, dense pellets. You easily adjust density, shape, and whether pellets sink or float. It also has auto-feeding, temperature control, cutting, and linked drying—all in one system.

01 Advanced Raw Material Processing

Advanced Raw Material Processing

Uses high-temperature, high-pressure extrusion to fully gelatinize starches for better fish digestion. Moderately denatures proteins to reduce anti-nutrients and enhance intestinal absorption.

Thoroughly mixes oils, vitamins, minerals, and other additives into the base ingredients for balanced nutrition in every pellet.

02 Custom Pellet Shaping

Custom Pellet Shaping

Adjustable die holes and cutting tools control pellet diameter, length, and shape.

By regulating pressure and moisture, density is customized to produce floating, sinking, or slow-sinking feed.

03 Pathogen Kill & Freshness Protection

Pathogen Kill & Freshness Protection

The extrusion process eliminates over 90% of harmful microbes, reducing fish diseases.

Post-extrusion drying lowers mold risk during storage/transport—critical for humid regions—extending shelf life.

04 Automated Precision Control

Automated Precision Control

PLC systems monitor/regulate barrel temperatures in real-time to stabilize gelatinization.

Feed rate motors sync input with output speed, preventing blockages or weak pellets.

05 Broad Ingredient Compatibility

Broad Ingredient Compatibility

Processes common (corn, soybean meal, fish meal, bran, distiller’s dried grain) and unconventional materials (algae powder, insect protein, botanical extracts).

Auto-adjusts screw speed/die size based on ingredient properties (fiber/moisture content), minimizing downtime for formula changes.

APPLICATION OF Fish Feed Extruder

RICHI fish feed extruder machine is a versatile aquatic feed production machine for making aquatic feed. It works great for fish, shrimp, crab, shellfish, soft-bodied animals, turtles, and even pet food like cat/dog.

When making feed with a fish feed extruder, different ingredient recipes directly impact the pellets’ nutritional value and water stability. To ensure good pellet formation, you must adjust the raw materials based on the fish or shrimp or pet species, growth stage, and farming conditions.

Extruded Shrimp Feed Production with fish feed extruder

It can produce shrimp feed pellets that sink to the bottom of the water and can remain in the water for a long time without being easily deformed, so as to meet the production needs of different types of shrimps and crabs.

Extruded Pet Food Production with Fish Feed Extruder

RICHI fish feed extruder can produce pet food in different shapes and sizes to meet the feeding needs of some pets such as cats, dogs, turtles, etc.

Extruded fish feed production With Fish Feed Extruder

For fish feed extruders, two common choices exist: If your needs are simple, you can purchase this equipment alone and use it to complete the feed pelletizing. If you need to build a large-scale feed production system, you can also integrate it into a complete fish feed production line as a core component of the feed processing plant, working with other processes.

Target users and industry

With flexible operation and broad processing capabilities, RICHI fish feed extruder machines deeply adapts to diverse target users and industry scenarios. From batch-customizing single-formula feeds to continuously producing multi-category feeds, or efficiently processing special raw materials–our fish feed extruder machines consistently deliver quality-compliant feed pellets.

Target users and industry

Fish Feed Extruder: BUILDING Your Complete Aquatic Feed Production SOLUTION

In the fish feed production, a single fish feed extruder machine can’t handle the entire process alone. It often works with crusher, mixer, dryer, sprayer, cooler and packaging equipment to form a complete fish feed production line.

The production line specifically includes raw material reception/processing, crushing, mixing, extrusion, drying, spraying, cooling,screening, and packaging sections.

This setup is flexible. They can be flexibly added or removed based on needs. In some cases, the extruder can even be replaced with a pellet mill to further adapt to different production requirements.

Pre-processing

Use a powder material cleaning sieve to remove fine sand, small stones, metal debris, dust clumps, etc., and meanwhile break up slightly agglomerated material.

Crushing

Granular raw materials need to be crushed before extrusion. Depending on production needs, an ultra-fine grinder can be used for secondary crushing.

Mixing

According to the feed formula, the crushed materials and the vitamins, premixes, oils, etc. that need to be added are sent to the feed mixer for uniform mixing.

Extrusion

The mixed ingredients are processed with high temperature, pressure, and moisture inside the fish feed extruder. This cooks them thoroughly and kills bacteria.

Drying

Dryer dries the moisture content of feed pellets to between 10% and 11%, which is convenient for subsequent processing and can be stored for a long time.

Spraying

The dried puffed feed pellets are sprayed through a spray device to increase the fat content in the puffed feed pellets and improve the palatability of the feed pellets.

Cooling

Lowering the feed pellet temperature to near room temperature. This helps evenly distribute moisture and prevents cracking or condensation.

Packaging

Using fully automatic packing equipment, finished feed pellets can be packaged into bags for easy storage, transportation and sales.

Our existing feed production solutions

Drawing on years of feed engineering expertise, we’ve developed a range of proven feed production solutions tailored to diverse animal species and formula characteristics.

Our comprehensive systems cover fish/shrimp feed, pet food, and livestock/poultry feed applications. (→To learn more, click the title to go to the corresponding page.)

Application Cases of Fish Feed Extruders

RICHI Machinery is a professional turnkey solution provider for fish/shrimp feed production lines. We offer more than equipment— we deliver fish feed production project service, providing customized, complete solutions.

Every successful project begins with clearly understanding customers’ goals. (→ Click the title to jump to the corresponding case page)

FAQ ABOUT FISH FEED EXTRUDER

If you have any questions about extruders or feed production, you can first take a look at these answers.

1. What types of fish feed extruders do you offer?

+

We offer different kinds of fish feed extruders to fit different needs.

We have dry extruders that don’t use steam, which are good for making floating feed. We also have wet extruders that use steam to cook the feed better, for higher quality output.

If you need different levels of production, we have single-screw models for small or medium output, and twin-screw models for large output or feeds with high fat or special formulas.

2. What raw materials can be used with your fish feed extruders?

+

Our fish feed extruders can use many different raw materials.

Common ingredients are fish meal, soybean meal, and insect protein for protein. Corn, wheat, and rice bran are often used for energy.

You can also add oils like fish oil or plant oil to give the feed more energy. Vitamins, minerals, and binders can be added too, to make the feed more nutritious and hold together better.

3. How should I choose the right fish feed extruder ?

+

First, think about how much feed you need to make each hour.

Next, decide what type of feed you want — floating, sinking, or high-fat.

Also, choose the level of automation: manual control or automatic with a PLC system.

Finally, pick the machine that fits your budget and gives you good value.

4. Do you offer installation and training services?

+

Yes. We believe after-sales service is very important. So, along with our quality machines, we offer full support.

This includes installing and testing the machine on site so it can start working right away. We also provide full training for operators.

If you have any technical issues, we offer long-term support and quick delivery of spare parts.

5. How can I get a quote for the equipment ?

+

The price of fish feed production lines, including extruders, pelletizers, crushers, and mixers, depends on the model and how much it can produce. Prices can be from a few thousand to hundreds of thousands of dollars.

To get an exact quote, please tell us what you need, like how much you want to produce, what type of feed you want to make, and if you need automatic control.

You can contact us by phone at +86 19513373095, by email at enquiry@fishfeedequipment.com, or by filling out a form on our website. We will give you full pricing and service details.

6. What is the fish feed extrusion process?

+

The commercial fish feed extrusion process, in simple terms, involves using a fish feed extruder to apply pressure, heat, and moisture to pre-mixed feed ingredients within a short time for processing.

There are two main heating methods: one relies on frictional heat generated by the machine (called dry extrusion), while the other involves preheating the ingredients before injecting steam (called wet extrusion).

This process can handle common raw materials like soybeans, corn, rice, and peas, as well as high-moisture content ingredients. It mainly includes two types: dry type and wet type.

Dry extrusion process: During processing, no additional water or steam is added. Heat is entirely generated through mechanical friction, while the screw applies pressure to force the ingredients out of the die mold. Once extruded, the sudden drop in pressure causes the moisture in the ingredients to evaporate. Throughout this process, the moisture content of the ingredients remains between 15% and 20%.

Wet extrusion process: The principle is similar to that of dry extrusion, but it requires additional water and steam injection, raising the moisture content of the ingredients to 20% or even above 30%, since heating primarily relies on the injected steam.

Still looking for — ?

If you’re not yet satisfied with the fish feed extruders introduced earlier, don’t worry!

Continue reading to see more fish/shrimp feed pellet mills, feed production line solutions, and customer cases.

→ Click the corresponding button to explore options better suited for you.

Pet Food Machine

Specializing in the production of cat food, dog food, hamster food, and bird food.

Fish Feed Pellet Machine

Be used to produce fish feed, shrimp feed and various livestock and poultry feed.

Shrimp Feed Making Machine

Adapted to the digestive characteristics of shrimp, producing sinking or slow-sinking shrimp feed.

INSIDE RICHI MACHINERY

Our business centers on aquatic feed machinery. We don’t just research, develop, and manufacture core equipment like fish feed extruders, fish/shrimp feed pellet machines, and pet food extruders. Plus, we offer complete feed production solutions, helping you set up fully integrated plants for producing fish/shrimp feed or dog & cat food.

Through top-quality products and services, we’re reshaping the global image of ‘Made in China’.

30

RICHI Machinery

has been around for 30 years.

We are a top maker and supplier of machines for fish/shrimp/crab feed and pet food. For many years, our fish/shrimp feed equipment have reached the USA, Canada, Russia, Uzbekistan, Ukraine, Iran, Indonesia, Romania, Angola, Pakistan, Ethiopia, the UK, etc.

300+

We have helped build hundreds of fish/shrimp feed production lines from scratch.

140+

Our feed pelletizing equipment has been sold to more than 140 of the more than 200 countries and regions in the world.

International

Certification

All our equipment has passed ISO9001:2008, CE, CU-TR and other certifications.

1000+

We now offer our related services to so many feed producers worldwide.