CUSTOM FISH FEED MILL SOLUTIONS

Build your efficient fish feed factory with RICHI’s all-in-one fish feed mill solution.

From planning to successful production — we help you stand out in the aquafeed market!

If you raise fish or shrimp, or run a feed mill, do you often think like this:

“Specializing in the fish and shrimp feed market is stable enough, but if I could also make pet food, wouldn’t my customer base be even wider?”

“Can one production line make both fish and shrimp feed? Switching products is messy and expensive—isn’t there a flexible solution?” ……

Both ideas lead to one smart solution: Invest in a complete feed production line.

You might ask, “Can’t I just buy a single feed pellet machine?”

Sure, one fish feed pellet machine handles pieces of the job. But it misses critical steps: grinding raw materials, precise mixing, plus post-pellet cooling/screening. Inconsistent connections between different pieces of equipment can also lead to production disruptions, impacting efficiency.

And a complete feed mill solution can solve this. We offer:

OVERVIEW OF FISH FEED MILL SOLUTIONS

Different aquaculture goals have different feeds. So choosing the right fish feed mill solution can reduce detours. RICHI has always kept these needs in mind, offering diversified feed mill solutions tailored for every aquaculture feed plant project.

Floating Fish Feed Mill Solution

We’ve got custom floating fish feed production lines—capable of 0.5 to 20 tons per hour—all from a pro manufacturer of feed pellet equipment.

Trout Feed Mill Solution

Tilapia Feed Mill Solution

Sea Bass Feed Mill Solution

Salmon Feed Mill Solution

Eel Feed Mill Solution

Koi Feed Mill Solution

Sinking Fish Feed Mill Solution

We’ve got custom floating fish feed production lines capable of 0.5 to 20 tons per hour-all from a pro manufacturer of feed pellet equipment

Grouper Feed Mill Solution

Pangasius Feed Mill Solution

Sturgeon Feed Mill Solution

Catfish Feed Mill Solution

Seabream Feed Mill Solution

Carp Feed Mill Solution

Shrimp Feed Mill Solution

We’ve got custom floating fish feed production lines capable of 0.5 to 20 tons per hour-all from a pro manufacturer of feed pellet equipment

Pacific White Shrimp Feed Mill Solution

Black Tiger Shrimp Feed Mill Solution

Indian White Shrimp Feed Mill Solution

Indian White Shrimp Feed Mill Solution

Giant Freshwater Prawn Feed Mill Solution

Banana Shrimp Feed Mill Solution

Pet Food Mill Solution

We’ve got custom floating fish feed production lines capable of 0.5 to 20 tons per hour-all from a pro manufacturer of feed pellet equipment

Dog Food Mill Solution

Cat Food Feed Mill Solution

Hamster Feed Mill Solution

Turtle Feed Mill Solution

Parrot Feed Mill Solution

More Pet Food Mill Solution

Multi-functional Feed Mill Solution

Our multi-functional feed pellet production lines offer a wider range of applications. You can chooe to produce feed solely for aquatic animals, such as fish and shrimp.Or you can produce feed for both aquatic and terrestrial animals, such as fish and cattle, shrimp, and chicken, all on the same line.

This line can meet the production needs of different product categories by adjusting certain process steps.

Fish & Chicken Feed Mill Solution

Fish & Duck Feed Mill Solution

Fish & Cow Feed Mill Solution

Fish & Sheep Feed Mill Solution

Fish & Pig Feed Mill Solution

Aqua & Livestock & Poultry Feed Mill Solution

FISH FEED MILL SOLUTIONS CAPACITY

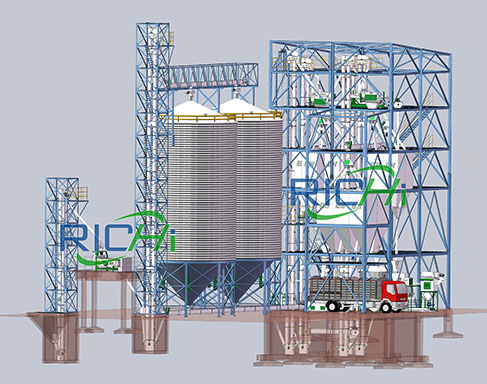

Production capacity ranges from 0.5 to 40 tons/hour. RICHI offers fish feed mill solutions for fish, shrimp, and crab feed across various scales. Whether for small or large factories, you’ll find a suitable production capacity.

Below are typical feed production line or plant configurations tailored to different capacities for your reference.

FEED PRODUCTION PROCESS AND REQUIRED EQUIPMENT

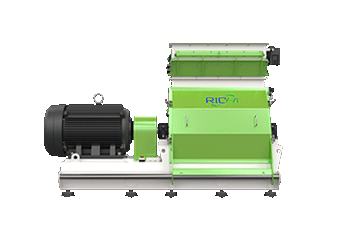

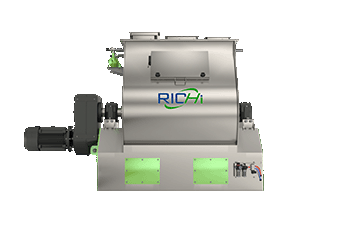

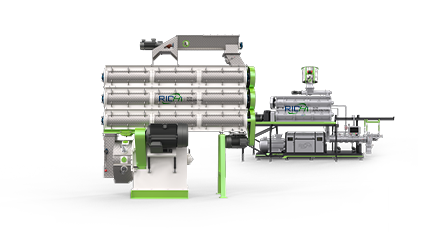

We can provide a complete set of feed production equipment for feed pellet production line, including hammer mill, feed extruder, feed pellet mill, drying equipment, and feed spraying equipment.

With a professional R&D team, cutting-edge technology, advanced production equipmen tand more than 60,000 square meters of modern production workshop, we can deliver each set of aquatic feed production equipment to our customers with the highest industry quality standards.

Crushing -Mixing -Pelletizing/Extrusion -Drying -Spraying-Cooling -Screening- Packaging

01 Crushing

For juvenile fish and shrimp, the raw materials are ground finer for easier digestion. For adult fish and shrimp, the pellets can be slightly coarser. This allows for smoother mixing and pelleting.

02 Mixing

Whether it’s high prctein fish meal ornut ritional supple ments like vitami nsand minerals, theyre all mixeda ccording to your specifed formula This way. you don’t have to worry about some fish and shrimp eating more than others. leading to different growth rates.

03 Pelletizing/Extrusion

Your desired floating and sinking feed, as well as pellet size, are determined in this step. The raw material powder is pressed into your desired shape in the machine, and the high-temperature pressing process also sterilizes the material.

04 Drying

The pellets are initially moist and require drying to ensure longer storage and prevent mold.

05 Spraying

If you wish to add volatile nutrients, such as fish oil or special vitamins, to the feed, this step involves spraying them directly onto the pellet surface.

06 Cooling

Freshly dried or sprayed pellets are still hot. Bagging them directly will trap moisture and cause them to clump. This step lowers the temperature, making subsequent packaging and storage easier.

07 Screening

Inevitably, there will be broken particles and fine dust in the feed. This step removes these “unqualified” particles, leaving only intact, uniformly sized pellets. This ensures consistent feed quality, with no variability.

08 Packaging

Finally, the feed is neatly bagged or barreled for easy transport and storage. You can feed or resell it right away, worry-free.

Explore Our Fish Feed Mill Solutions – Real Cases

Thanks to our comprehensive service and reliable equipment quality, more and more customers have successfully established efficient and stable feed plants with our support.

5T/H Fish Feed

Production Line in Russia

Located in Russia, primarily produces feed pellets for submerged fish. All the fish feed pellet equipment for the production line was completed within 120 days.

500kg/h Floating Fish Feed Production Line in Côte d’Ivoire

Be primarily used to produce floating fish feed. The customers owns their own aquaculture farm, and the feed produced is used for their own farm.

2.5T/H Pet Food Production Line in China

This pet food production project, located in China, primarily produces high-fat feed for cats, dogs, and other pets.

5T/H Fish Feed Production Machine in Uzbekistan

Producing feed pellets for submerged fish. Poultry feed pellet production is currently under discussion.

2T/H Indonesia Shrimp Feed Production Line

Uses to produce shrimp feed pellets. This customer invested in and built a shrimp feed pellet machine in Indonesia.

HOW TO BUILD A FISH FEED MILL?

If you’re planning to build your own fish feed factory, the first step is to clearly determine the type of feed you want to produce. Is it a floating fish feed, a sinking fish feed, or a specialized shrimp feed? Alternatively, you might want to create a comprehensive feed mill that can cater to multiple aquaculture needs. Once you’ve determined your goals, you’ll have a clearer direction for formula, equipment, and plant operations.

With this direction in mind, it’s time to consider the details of the factory’s operations:

01. Feed Formulation

Determine which raw materials are used toproduce the feed, Some feed pellet produc-tion equipment requires configurationbased on the raw materials.

02. Feed Processing Plant Capacity

After a feed plant is built, the number of tons of feed it needs to produce per hour or per day is directly related to the model and quantity of feed pellet production equipment and the overall layout of the feed production line.

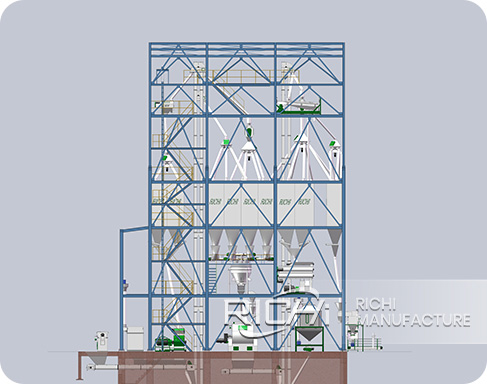

03. Feed Project Site Area and Height

Evaluate the available plant area and height for the feed processing plant. The feed production line design and equipment layout will ultimately need to be tailored to site conditions.

04. Investment Cost Estimation

Different budgets correspond to feed pellet production line solutions with varying scales, capacities, and levels of automation, as well as corresponding feed pellet production equipment. Appropriate investment planning can not only improve production efficiency but also maximize returns on investment.

1

I only have a small factory. Can I accommodate a complete production line?

No problem. Our production line has various layout options and can be designed to suit your factory space. Even if you only have a few hundred square meters, we can help you plan the equipment layout appropriately.

2

How much does a production line cost? Can you tailor a plan to your budget?

It’s difficult to give a flat rate price for this, as it depends on your production volume, level of automation, and number of machines. But rest assured, simply tell us your budget and we’ll help you design a suitable solution.

3

Can you provide me with a feed formula?

Yes, we can. We’ll provide you with a basic formula to facilitate your initial trial production. However, please note that formulas are highly tailored to local conditions.

Factors like local raw material availability and prices, as well as the adaptability of fish and shrimp to local ingredients, can all influence the results.

The formula we provide is a starting point to help you get started quickly.

Once your production is running smoothly, if you’d like to optimize the system to better suit your farming needs, you can contact a local formula expert for further optimization.

4

How many people are needed to operate a production line? Is the operation complex?

Actually, it doesn’t require too many people. A small production line generally requires 3-4 people, while a larger one can be handled with 5-6. Our machines are all automated, with intuitive user interfaces. If needed, we’ll send engineers for on-site hands-on training. Your employees can operate the system independently in just a day or two, without delaying production.

5

What if there’s a problem with the machine? How can I resolve it locally? Can you provide remote guidance?

For most issues, we can help you resolve them remotely via video link, guiding you through the troubleshooting step by step. Some customers get nervous when they encounter a problem for the first time, but most are minor issues. For more complex situations, we’ll reassess whether to send an engineer. We also stock common wearing and spare parts in advance, ensuring you don’t have to wait for parts to delay production.

FISH FEED MILL SOLUTION DESIGNER–RICHI MACHINERY

Founded in 1995, RICHI Machinery Co., Ltd. is a manufacturer of feed machinery processing equipment and complete plant engineering, primarily focused on the feed machinery industry. We specialize in animal feed pellet mills, aquatic feed pellet mills, wood chip pellet mills, grain storage systems, and steel structure buildings. The research and development and production of aquatic feed pellet mills are a crucial component of our business.

In the aquaculture field, we offer complete production lines including fish/shrimp/crab feed pellet machines, feed extruders, crushers, mixers, dryers, coating systems, coolers, sieving equipment, and fully automatic packaging systems. We can customize efficient and energy-saving feed production solutions for customers according to the needs of various aquatic animals and pets.

Equipment Production

RICHI has a modern machining workshop and a complete quality control system, covering the entire production process including raw material cutting, welding, assembly, and inspection. All feed equipment is manufactured by an experienced technical team.

Technical Communication

We provide process consultation and formula guidance in the early project stages. During installation and commissioning, we offer on-site training and operational explanations. Additionally, we continue to deliver technical support and upgrade suggestions afterward.

Qualified Certification

Each piece of equipment undergoes rigorous performance testing and safety inspection before leaving the factory, complying with international quality certification standards such as CE and ISO.

If you have any questions, please contact RICHI Machinery. Your dedicated customer service manager will provide a one-stop, worry-free solution.