fish feed pelleting machine for sale

Find the right pelleting machine capacity for your daily fish feed production, from 0.3 T/h and up.

Clear capacity options designed for real, long-term operation and suitable for fish, shrimp, crab feed, and cat and dog food pellets.

RICHI MACHINERY

How to Choose the Right Fish Feed Machine for You?

The market for fish feed machines is vast, with many different specifications and configurations. It’s understandable to feel overwhelmed when choosing, not knowing which model is the best fit for your farming or production needs.

Don’t worry! We’ll provide you with an easy-to-understand selection guide based on two key factors: core production capacity and critical process configuration. This will help you quickly find the perfect machine.

If you need more than just a single pelleting machine, we also offer complete fish feed production lines in various capacities for you to choose from.

Fish Feed Pelleting Machine to

Fit Any Production Capacity

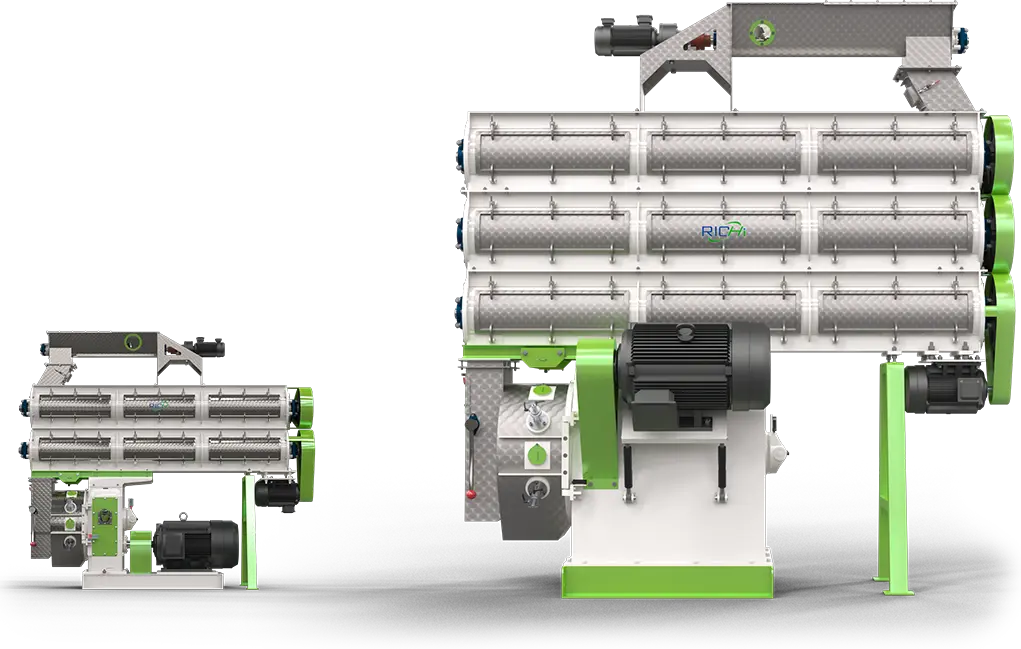

RICHI offers fish feed pelleting solutions covering all capacity ranges. Among them, six models cater to small-batch to medium-scale production needs, which are commonly chosen by most customers in practical use.

0.3-0.4 T/H Fish Feed Machine

Although it is the fish feed machine with the smallest production capacity, it is sufficient to produce a variety of fish feed. With a small footprint and simple operation, it is recommended for farmers who do not have a large daily demand for feed.

Power: 37kW

Investment advice: Entry-level model

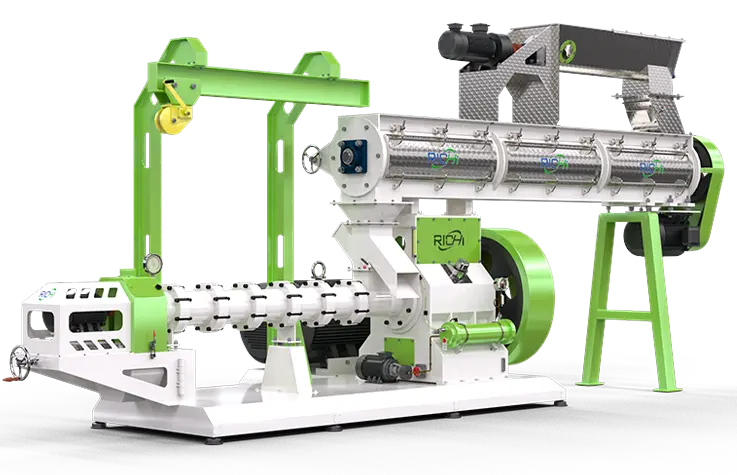

0.5-0.6 T/H Fish Feed Extruder Machine

Can produce up to 4000 kg per day with 8 hours of operation. It can process a variety of fish feed raw materials, easily meeting the nutritional requirements of different fish species.

Power: 55 kW

Investment advice: For small-scale farms, meeting the nutritional needs of multiple fish species.

0.8-1.0 T/H Fish Feed Making Machine

Steam cooking + single screw extrusion ensures high maturity and excellent nutrient retention in finished feed pellets.

Power: 75 kW

Investment advice: For farmers who have requirements for the quality of feed pellets.

1.5-2.0 T/H Twin Screw Fish Feed Extruder

The twin screw design can handle more complex raw materials and produce the highest quality feed. It is suitable for aquatic feed, and can also process pellets for pets such as cats and dogs.

Power: 90kW

Investment advice: For medium-sized farms / feed mills that also handle pet food processing.

3-4 T/H Fish Feed Pellet Machine

Its core advantages are high production capacity and low energy consumption, with simpler equipment operation and lower maintenance costs. In addition to producing sinking fish feed, it can also process land animal feed.

Power: 37kW

Investment advice: Multi-purpose users of aquatic/livestock feed.

5-6 T/H Aquatic Feed Pellet Machine

Featuring a three-layer conditioning structure, equipped with reinforced pressure rollers and ring die system, it can produce high-quality shrimp feed pellets that have high density, strong water resistance, and good crack resistance.

Power: 55kW

Investment advice: For shrimp/fish farming.

Want higher capacity? Custom solutions available!

Tailored to Your Operation

We adapt our machines to you. Key performance indicators like capacity and core processing settings

can be tailored to fit your unique production demands.

Fish Feed Pellet Machine for Different Production Processes

For superior fish feed pellet quality, appearance, and flexibility, you’ll generally need to invest in more sophisticated, higher-spec machinery.

Important: Ring die feed pellet machine work for many feed types (like animal and fish feed), but its setup is different from machine only for fish feed (extruders). So, we won’t compare it directly here.

Complete Fish Feed Production Line Solution

The core equipment for fish feed production is the extruder and pellet mill. To achieve industrial-scale, long-term stable, and high-volume production, a complete production line solution is necessary to ensure continuous operation and consistent product quality.

Depending on your needs, you can choose a standard, single-product feed production line, or opt for a versatile multi-product line. This allows your factory to cover more products and customer groups with a single investment.

Fish Feed Production Process

Whether you’re making floating fish feed, sinking fish feed, or shrimp feed, a complete production line always follows this entire process: Grinding → Mixing → Pelleting/Extrusion → Drying → Coating → Cooling → Packaging.

Many customers often ask: What is the function of each step? What core equipment is needed? Which stages affect pellet density, expansion rate, and water stability?

Below, we will break down the entire production flow, so you can quickly understand how each step works, what equipment is used, and how to ultimately achieve stable and uniform fish feed pellets.

Core Machinery & Auxiliary Systems for Fish Feed Lines

Hammer Mill

Breaks raw materials into smaller, more digestible particles.

Paddle Mixer

Ensures the feed’s nutrients are uniform.

Fish Feed Pelletizer

Determines the pellet’s shape, density, and buoyancy (float/sink).

Belt Dryer

Prevents pellets from becoming damp or moldy.

Vacuum Sprayer

Adds oil, attractants, and probiotics to make the feed more nutritious.

Counter-flow Cooler

Sets the pellet’s shape, so it’s firm, not oily, and doesn’t stick together.

Vibrating Screen

Removes powder and broken pellets.

Fully Automatic Packaging Machine

Various packaging sizes are available to meet the needs of farmers and distributors.

RICHI Completed Projects

With years of deep expertise in the R&D and manufacturing of fish feed equipment, RICHI has successfully completed numerous delivery projects worldwide.

From single-machine solutions for small-scale production to large-scale automated factories, we consistently build highly stable and cost-effective production systems for our clients, adhering to the standards of a professional fish feed machinery manufacturer.

Below are some of our project cases that have been commissioned and are operating stably long-term, helping you to more intuitively understand our capabilities and delivery capacity.

RICHI machinery video

RICHI Machinery began as a professional manufacturer in feed pellet machine, and has now developed into a comprehensive solution partner for both feed pellet equipment and complete pellet plant systems. We take great pride in our team’s expertise and skills—from technical sales to process design engineers, every member is committed to supporting our customers. You can confidently choose RICHI to elevate your business.