FISH FEED PRODUCTION LINE

Build your own high-performance fish feed production line — powered by RICHI Machinery’s advanced fish feed machines and one-stop service.

1000+ global installations. From design to commissioning, we make your fish feed plant run smarter and smoother.

CHOOSE PROFESSIONAL

FISH FEED PRODUCTION LINE MANUFACTURER

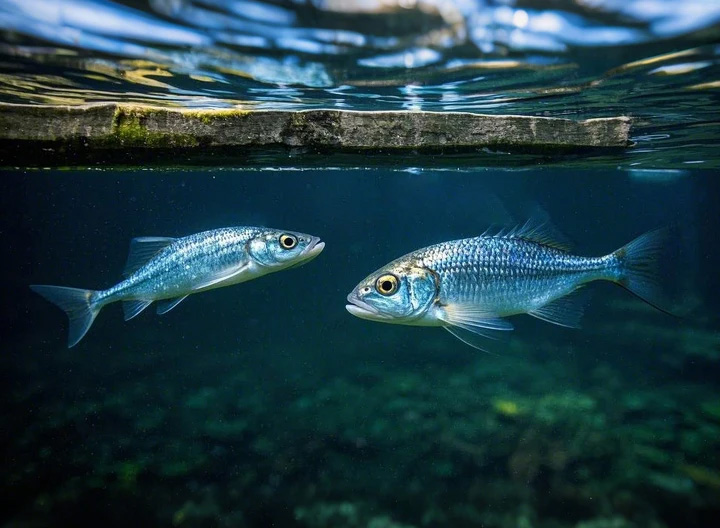

Fish feed production line is a set of automated equipment used to produce fish feed. It can also make feed for shrimp and crabs. It is both special and multi-use.

Wheat, corn, fish meal, soybean meal, and other raw materials go through many steps on this line. They become high-quality fish, shrimp, or crab feed with uniform size and good nutrition.

Complete Process Flow

We can also customize a dedicated fish feed process flow based on your specific needs.

Crushing

Mixing

Pelletizng

Drying

Packaging

Cooling

Spraying

At RICHI Machinery, we believe that purchasing equipment is just the beginning and its true value lies in helping you achieve smoother, more worry-free aquaculture production.

That’s why we don’t want to just be your fish feed equipment seller, but to be your partner. We’ll stick with you through every step of the aquatic feed production line, from raw materials to finished products, making sure everything connects perfectly.

Flexible Fish Feed Production Lines Covering Fish & Shrimp Feed, and Pet Food Applications

Fish feed production lines were initially designed for processing all kinds of fish and shrimp feed. However, thanks to technological advances, their capabilities now extend far beyond that.

By adjusting formulations, dies, and extrusion processes, a single production line can flexibly switch between producing fish feed, shrimp feed, or even pet food—enabling truly versatile applications.

In RICHI’s system design philosophy, these lines are not just single-purpose machines; they are multifunctional feed production systems.

This highly scalable design allows factories to efficiently use equipment resources, easily adapt to different feed requirements, and unlock new opportunities in the pet food and specialty animal feed markets.

How Are Fish Feed Pellets Produced?

When many farmers start to invest or run fish feed production, they always ask, “How do I do this? What’s the production process? ” In RICHI, we don’t just give you a fixed plan, instead will tailor your fish feed production process according to your raw materials, plant size and budget.

The whole process——from raw material crushing and mixing, to extrusion, drying, spraying, cooling, and then to molding and packaging——every step is carefully controlled. The fish feed made in this way has even in size, balanced in nutrition, and has a texture your fish will love. It makes daily production smoother and easier, and also helps your farming profits keep steady.

01

Raw Material Processing

This is the first step in the production process of fish feed. It is necessary to carefully pick and clean fish meal, soybean meal, corn and other raw materials to remove impurities and ensure that the raw materials are clean and safe. Only when this step is done right, the following production steps can proceed smoothly.

02

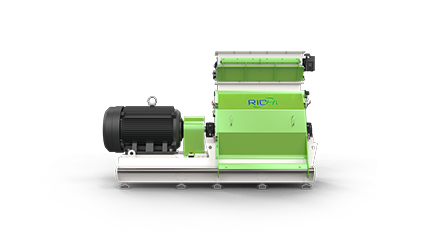

Crushing

Large pieces of fish meal, corn and other raw materials are ground into fine and uniform powder, which lays the foundation for mixing and pellet-making later. The crushing degree can be flexibly adjusted according to the feeding habits and growth stages of different fish, so that the particle size is just right for fish to eat.

03

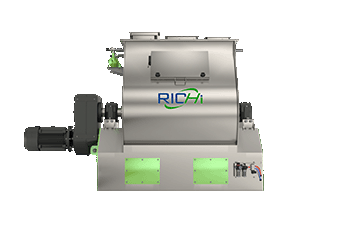

Mixing

All raw materials are fully blended according to the formula, so that protein, fat, vitamins and other nutrients are evenly distributed. In this way, every single fish feed pellet tastes the same, and the fish can eat more happily and can absorb nutrients better too.

04

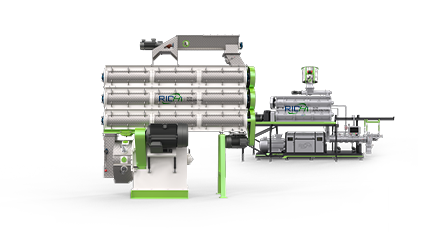

Pelletizing & Extrusion

This is the most critical steps in fish feed production. The powdery mixture is extruded to become floating, sinking or slow-sinking pellets, and each one is uniform in size and stable in structure. For fish, it is easier to eat; For farmers, it also means higher feed utilization rate and less waste.

05

Drying

According to the type of pellets and how much moisture they have, the drying temperature and time will be flexibly adjusted to ensure that each batch of fish feed is dry and uniform. In this way, it’s not just convenient for later storage and transportation, but farmers also don’t have to stress constantly about the feed going bad or breaking apart.

06

Spraying

Spraying is to coat the surface of fish feed with a layer of nutrition or fat. This step can increase feed’s flavor and makes it more appealing to fish. Not only does it improve the appetite of fish, but it also make each batch of fish feed more valuable and more popular in the market.

07

Cooling & Screening

After drying and spraying, the pellets need to go through cooling and screening. This brings the feed to a nice temperature, makes sure the hardness is even, and gets rid of broken materials and dust. This step ensures that every fish feed is intact, which also makes packaging and storage more convenient.

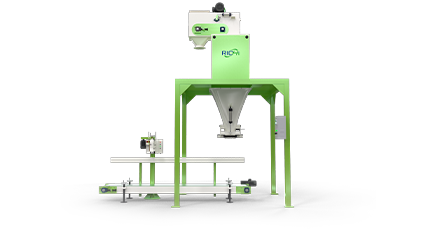

08

Packing

The last step of fish feed production process. Automatic packing equipment can complete weighing, sealing and warehousing according to specifications, so that each bag of fish feed is clean, tidy and easy to manage. That way, you can easily store and distribute feed, saving time and effort.

Are you dreaming of becoming an aquatic feed manufacturer? Eager to kickstart your very own aquatic feed production business? Don’t hesitate—reach out to us now, and let’s turn that vision into reality!

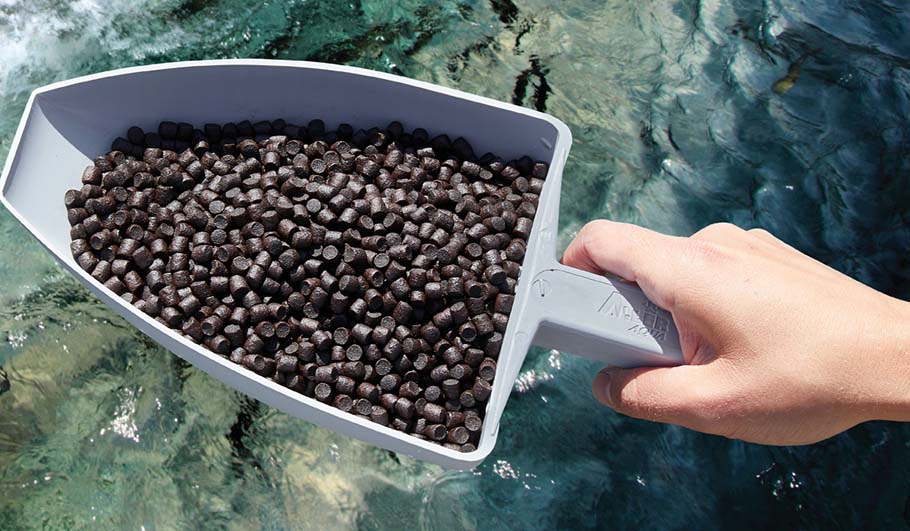

LOOK AT THE FISH FEED PELLETS PRODUCED BY US

Through visual display, you can see our carefully made fish feed pellets. These pellets come from our fish feed production lines and machines, and they’re made to meet the growth needs of all kinds of fish and aquatic creatures.

Fish Feed Pellets

Solid fish feed pellets, produced by fish feed pellet mill and fish feed extruder, can be adjusted in size and hardness to suit the growth stage and species of the fish.

Solid fish feed pellets are a standard feed form in large-scale aquaculture.

Fish feed pellets

The basic raw materials for high-quality fish feed pellets are fish meal, soybean meal, grains and more. Through scientific proportioning, key nutrients such as protein, vitamins and minerals can be preserved.

Some pellets are also cured to enhance nutrient absorption.

Fish feed pellets

In terms of functional adaptability, fish feed pellets can be categorized as floating, sinking, or slow-sinking, which just correspond to the feeding habits of upper fish, bottom fish and middle fish.

Fish feed pellets

Fish feed pellets not only simplify the feeding process and reduce labor costs, but also precisely control the nutritional content of each pellet, avoiding growth difference of fish schools due to uneven feeding.

SUITABLE AOUATIC ANIMALS

Fish feed is just a customary name for the feed pellets processed by our equipment. It does not mean that our equipment can only make fish feed, or that we only have machines that make fish feed. The animals below only represent some common farmed species.

Catfish

Tilapia

Tilapia

Cichlids

Sturgeon

Ornamental Fish

Litopenaeus Vannamei

Freshwater Shrimp

Crab

Turtle

Cat

Dog

We’ve got numerous animals covered with our pelletizing equipment. Click the button today to explore our feed processing solutions!

HOW DOES FEED PROCESSING MEET THE DIFFERENT HABITS OF FISH?

Through scientific extrusion, drying and molding processes, fish feed can be made into different types: floating feed floats on the water surface, allowing fish to gather and eat; Sinking feed sinks to the bottom, perfect for bottom fish and less wasteful; Slow-sinking feed finds a balance between floating and sinking to meet the feeding habits of various fish.

The key to achieve this is to use fish feed extruder and fish feed pellet machine reasonably, and flexilbly customize the pellet specifications and formulas according to the fish species and farming mode.

FISH FEED PRODUCTION LINE

SOLUTIONS FOR DIFFERENT SCALES

Our fish feed production line covers a variety of output, so that each manufacturer can easily choose the most suitable solution.

1-2 T/H Fish Feed Production Line

ideal for not too big or newly established fish feed processing plants. It lets you easily adjust the output and pellet sizes, so you can experiment with different feed formulas and find the most suitable pellets and nutritional ratio for your needs.

1-2 T/H

Fish Feed Production Line

Ideal for not too big or newly established fish feed processing plants. It lets you easily adjust the output and pellet sizes, so you can experiment with different feed formulas and find the most suitable pellets and nutritional ratio for your needs.

8-10 T/H

Fish Feed Production Line

Ideal for large-scale fish farms and professional fish feed mills, it enables continuous production. Every step from crushing, mixing, extrusion, to drying is precisely controlled. That means each batch of fish feed pellets is uniform and nutritious.

15-17 T/H

Fish Feed Production Line

If you are planning to expand your factory, or want the factory to be able to produce different types of fish feed at the same time, this production line would be a good choice.We provide turnkey services from start to finish.

3-4 T/H

Fish Feed Production Line

Suitable for medium-sized fish feed processing plants or expanding farms, with stable output. Whether you’re raising tilapia, grass carp, or carp, this line ensures uniform pellets and a nutritionally balanced diet, making daily farming more worry-free.

10-12 T/H

Fish Feed Production Line

This high-yield fish feed production line is perfect for aquaculture farms that need a large daily output. Fish feed is no longer a “one-size-fits-all” approach. Regardless of the raw material mix or pellet size, we can make feed that fits different fish’s habits and growth stages.

18-20 T/H

Fish Feed Production Line

Designed for large-scale professional fish feed mills and large-scale aquaculture farms, this production line efficiently produces a variety of floating, sinking, and slow-sinking feed pellets. It supports continuous mass production.

5-7 T/H

Fish Feed Production Line

Medium-sized fish feed mills will find this line highly effective due to its efficiency and flexibility. This production line can make all kinds of fish feed pellets—floating ones, sinking ones, and the slow-sinking type too.

12-15 T/H

Fish Feed Production Line

It’s the perfect pick for large aquaculture farms. No matter how much feed you need to use daily, it can keep making high-quality pellets.

20-25 T/H

Fish Feed Production Line

It’s for those super big aquaculture companies, feed groups, and investors who’re into fish feed production. The work sections can be adjusted flexibly, and the raw materials and formulas can change however you need them to.

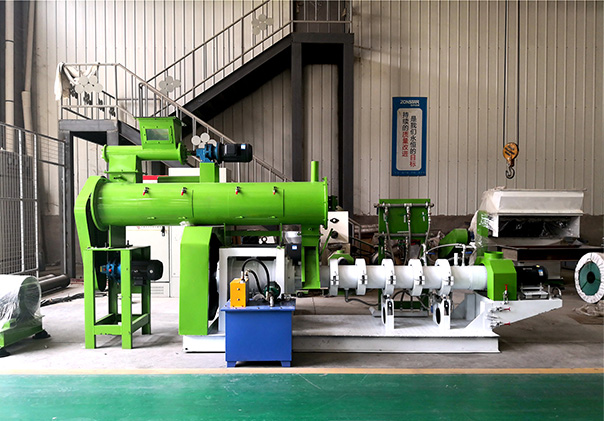

WHAT KEY EOUIPMENT DOES AN EFFICIENT FISH FEED PRODUCTION LINE NEED?

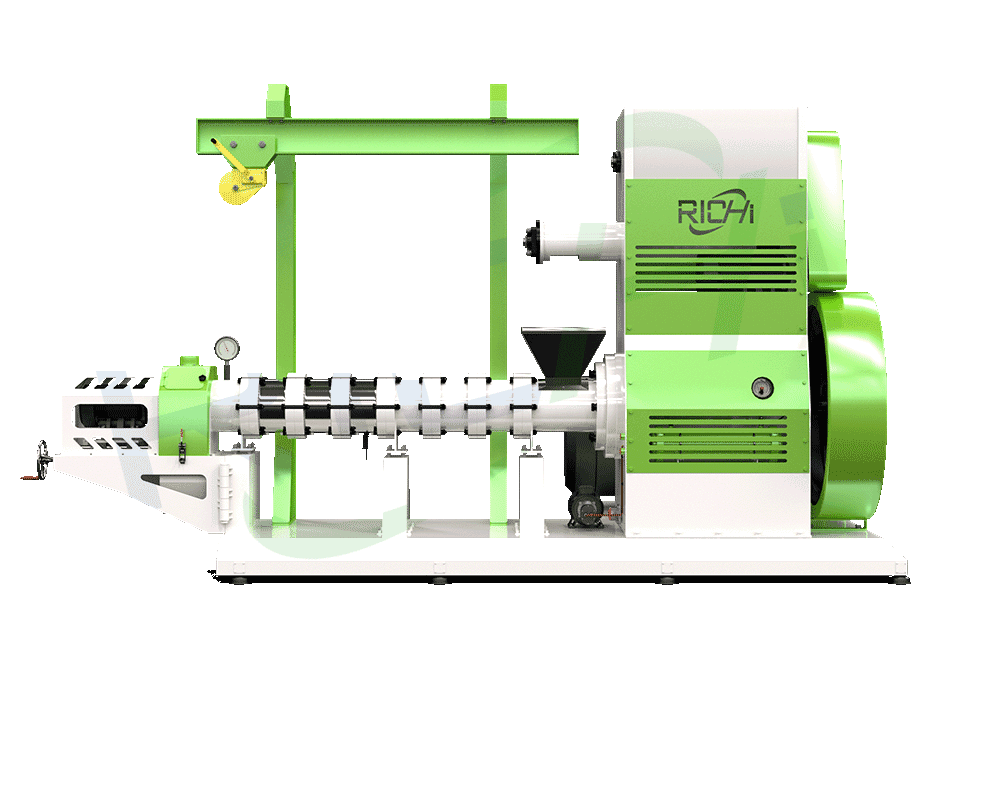

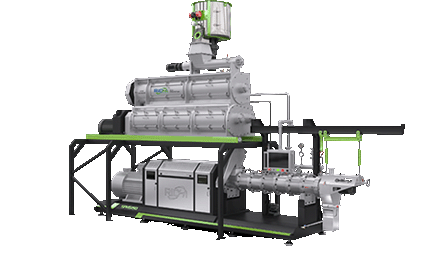

Fish Feed Extruder

Specially designed to adapt to a variety of fish feeds and aquatic feeds. And designed by RICHI professional engineers, service personnel and technical experts.

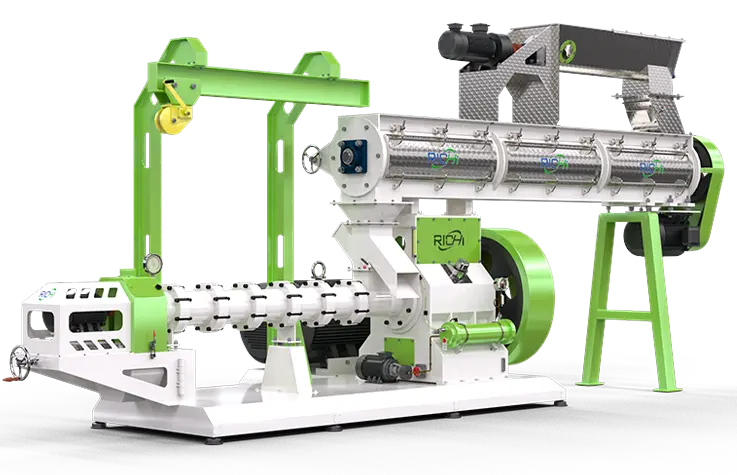

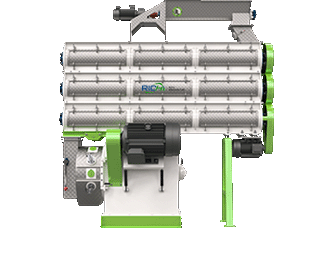

Fish Feed Pellet Machine

In the global market, RICHI has gained recognition for its high-performance fish feed pellet machine (or fish feed pelletizer), which has introduced many innovations in today’s pelleting field.

Investing in fish feed production line is actually investing in a full set of fish feed processing equipment. At RICHI, we don’t just tailor-make production plans for you, but also provide all the equipment you need. From raw material crushing and ingredient mixing, to pelletizing, drying, coating, cooling, screening, and packaging.

That includes fish feed extruders, fish feed pellet machines, dryers, crushers, screening equipment, and packaging machines. Every piece of equipment’s quietly doing its thing—getting the pellets just right and balancing the nutrition.

Click to chat with us online

REAL FISH FEED FACTORY SETUP CASES FROM CUSTOMERS WORLDWIDE

RICHI’s fish feed production line cases have spread across over 140 countries and regions worldwide, covering various fish feed pellet projects like floating, sinking, and slow-sinking types. Whether you want to build high value-added fish feed or have a high-yield and stable-running production line, we can combine rich practical experience to tailor a reliable fish feed production solution for you.

VIDEO TAKES YOU INTO FISH FEED PRODUCTION LINE

From raw materials to finished pellets, every step is inseparable from RICHI’s professional fish feed making equipment and fish feed manufacturing process. We believe that with leading one-stop fish feed production solutions, accumulated global experience and local service support, combined with our customers’ local industry knowledge, RICHI Machinery will drive new growth in your feed processing business.

Production Line Operation Video

Customer Factory Live Shot

Fish Feed Machine Installation And Commissioning Video

CUSTOMER REVIEWS

Our fish feed production lines have been entered factories around the world. Customers not only praise the equipment’s ease of use but also share their real-life experiences. Through their honest feedback, you’ll gain a more intuitive understanding of the value of RICHI equipment in aquaculture.

chat with us online

INSIDE RICHI MACHINERY

30

RICHl Machinery

has been around for 30 years

We don’t just develop and manufacture core equipment like fish feed extruders, fish feed pellet mills, shrimp feed pellet machines, crushers, dryers, and sprayers–we also put a lot of thought into providing customers with system solutions that make production lines more efficient and stable.

300+

We have helped build hundreds of feed production lines from scratch.

International

Certification

All our equipment has passed ISO9001:2008, CE, CU-TR and other certifications.

140+

Our feed pelletizing equipment has been sold to more than 140 of the more than 200 countries and regions in the world.

2000+

We now offer our related services to so many feed producers worldwide.

Adhering to the vision of “creating first-class enterprises, cultivating first-class talents, and making first-class contributions”, we are currently changing the world’s perception of Chinese products with excellent products and services.

Pre-sales Service

At the pre-sales stage, RICHI’s tech advisors and sales team act like your personal guides, ready to answer your questions via WhatsApp, email, or website messages.

Whether about equipment performance, specifications, or what it’s best suited for, they’ll patiently walk you through every detail so you can easily understand.

Even better, we’ll tailor a production plan based on your output needs, space, and budget, so you’ll know exactly which option fits you best before making a decision—no guesswork needed.

In-Sales Service

From the moment you place your order, our team is on it—tracking everything from confirmation to production scheduling to shipping updates—so you always know what’s happening.

During production, every component is carefully crafted to ensure your equipment runs reliably and smoothly.

When it’s time to ship, we choose the best logistics plan and make sure everything is packed and protected, so your equipment arrives safely and right on time.

After-Sales Service

From installation and commissioning, our tech team will be on-site to personally adjust every detail and provide hands-on instruction on how to use and what precautions to take.

Even after the equipment is up and running, we’re still stay by your side—answering questions, providing training, and optimizing upgrades, ensuring peace of mind.

FAQ About fish feed production machine & line

1. How do I choose the right fish feed production line for me?

+

Choosing a fish feed production line is really about looking at your own situation. Like, roughly how much output do you need each day? What raw materials do you usually use? Different fish species have different requirements for pellet size and formulas, too.

Besides that, you’ve got to think about your factory space and budget. Just tell us all this info, and we can help match you with a suitable plan, making subsequent production hassle-free and more tailored to your needs..

2. Why buy a fish feed production line? Can’t I just buy or use a single fish feed pellet machine?

+

A single fish feed pelletizer can indeed turn raw materials into pellets, but it only completes one step of the process. Other steps like crushing, mixing, drying, spraying, cooling, screening, and packaging need to be addressed separately.

In contrast, a complete production line connects all these steps, saving time and effort while also producing pellets with more consistent nutritional value and quality. Especially if you’re planning a long-term, large-scale operation, a production line will provide less worry and greater efficiency and effectiveness.

3. What’s the general price range for your fish feed production line?

+

There’s no fixed price for a fish feed production line, as it depends on your specific needs. Factors like output capacity, degree of automation, equipment configuration, and the types of raw materials processed all affect the investment cost.

Generally speaking, smaller-capacity lines have lower investment costs. Medium to large-scale production lines, while more expensive, offer more stable and long-term returns. Just let us know what you need, and we’ll provide a detailed plan and quote based on your situation, so you can have a clear budget in mind.

4. How do I know if I need to set up a fish feed production line?

+

If you regularly need a large amount of feed, or want to produce different types of pellets yourself (such as floating, sinking, and slow-sinking), then a production line would be a better fit.

In another case, if the cost of buying ready-made feed is high, or your aquaculture scale is gradually expanding, having a stable production line will not only make daily management easier, but also ensure more stable and higher profits.

5. What kind of services do you offer when I buy your products?

+

No need to worry about subsequent use. We’ll not only help you design and select the right equipment, but also send people to guide the on-site installation and commissioning. Once the equipment is running, we’ll also teach you step by step how to operate and maintain it.

If you run into any technical issues or require maintenance later, we’ll be there to support you anytime to ensure the smooth operation of the entire line. You just focus on production; leave the rest to us.

6. How long does it take to build and get the production line up and running?

+

The construction timeline depends largely on the scale of your project.

For a small production line, usually, everything from design to installation and commissioning can be finished in a few weeks to a month or two.

For medium to large ones, it might take around three months. We’ll work out a specific timeline based on your specific plan, and our team will monitor the entire process. You’ll know exactly how things are progressing at each step, so no need to worry about delays.

7. What raw materials can the production line process? And what types of fish feed can it produce?

+

Our fish feed production line can process a wide range of raw material. Common ones like corn, fish meal, soybean meal, wheat, and wheat bran are all fine, and we can also add supplementary ingredients flexibly as needed. The feed pellets produced can be floating, sinking, or slow-sinking. Whether you’re raising tilapia, grass carp, carp, or other fish, we can customize the pellet size and formula based on your fish’s feeding habits and growth stage, ensuring a more palatable and effective feed.

8. Can the production line be expanded or have automation modules added later?

+

Of course. Our production lines are designed with expansion in mind. You can start with a reasonable production volume and then upgrade to more automated modules, such as automatic batching and packaging. That way, the production efficiency gets a boost, and managing things becomes even easier.

9. Roughly how long is the investment payback period for building a fish feed production line?

+

The payback period depends on factors like output, raw material prices, and selling prices. Generally speaking, a small or medium-sized production line will recoup the investment in about a year, while larger ones may take longer. But with your own production line, you’ll have more control over feed costs and guaranteed quality. In the long run, the returns will only get more stable.

10. What are the benefits of a fish feed production line?

+

Owning your own fish feed production line means you take full control of the most critical aspect of aquaculture—nutrient supply. The benefits are direct and clear:

- You can source local ingredients directly, skipping middlemen and avoiding brand markups on commercial feeds. This slashes your cost per ton of feed significantly.

- Tailor formulas anytime for different species (grass carp, crucian carp, grouper, sea bass) and growth stages (fry, grow-out, broodstock). Customized nutrition boosts growth, strengthens disease resistance, and improves meat quality.

- From raw material procurement to processing, everything stays under your watch. You can eliminate poor-quality or banned additives, ensuring safe feed and trustworthy seafood products.

- Through controlled extrusion, feed pellets stay intact in water longer—reducing nutrient loss, cutting water pollution, and lowering the feed conversion ratio (FCR). Truly saving you money.

- You don’t have to worry about external feed price increases or stock shortages. You can flexibly adjust the formula based on market conditions. . Your fish will reach harvest size with better shape and higher prices, building your unique competitive edge.