2.5 T/h Pet food production line in China

Pet Food Production Line (Turnkey Project)

Production of pet food for cats, dogs, turtles…

Feed Specifications:

3-6 mm

Raw Materials:

corn, barley, oats and other grains…

Production Capacity:

2.5 tons per hour

Type:

Pet Food Production Line

CLIENT PROJECT DETAILS

This pet food production project is located in China and is mainly used to produce pet food pellets for cats, dogs, etc. It is a fully automatic pet food production line.

As the income level of residents continues to rise, more and more pet owners are raising pets, and most pet owners are also raising their requirements for pet food. Pet food has evolved from a single feed that can only meet the growth needs of pets to a feed that is rich in nutrition and tastes good.

Our client saw the development trend and potential of the pet food industry, so he decided to invest in building pet food production line.

After learning about some feed pellet machine manufacturers, the customer came to our factory for an on-site inspection. After seeing our feed production equipment and communicating with our technicians, they decided to choose us as their partner and build this pet food production plant with them.

With this pet food production line, customers can produce 2.5 tons pet food per hour. The feed food production line has been installed and officially put into operation.

CUSTOM-TAILORED PET FOOD PRODUCTION LINE SOLUTION

The main raw materials used in this 2.5 t/h pet food production line are some meats such as chicken and beef that can provide fat and protein; various grains, such as corn, barley, oats and other grains that can provide carbohydrates; in addition, there are minerals, vitamins and so on.

These raw materials can be used to produce pet food pellets of different shapes through the pet food production line.

This pet food production line is a fully automatic pet food production line. It is equipped with automated feed prouduction equipment from the receipt of raw materials to the packing of finished pellets. Therefore, the entire pet food production line has a relatively high degree of automation, which can greatly save manpower and improve production efficiency in the subsequent production process.

Crushing System

The entire feed production process involves two grinding operations. The first crushing uses hammer mill with main motor of 55kw and 2.0-aperture screen; the second crushing uses ultrafine grinder with main motor of 132kw and crushing fineness of 80 to 100 mesh. The crushed raw materials can meet the extrusion requirements.

01

Mixing System

The entire feed production process requires two mixing steps. Before the raw materials are crushed, they are batched on a batching scale and then mixed firstly. After mixing, they are crushed. After the crushing is completed, premixes, vitamins and other , etc. are added to the crushed raw materials, and then mixed for the second time mixing.

02

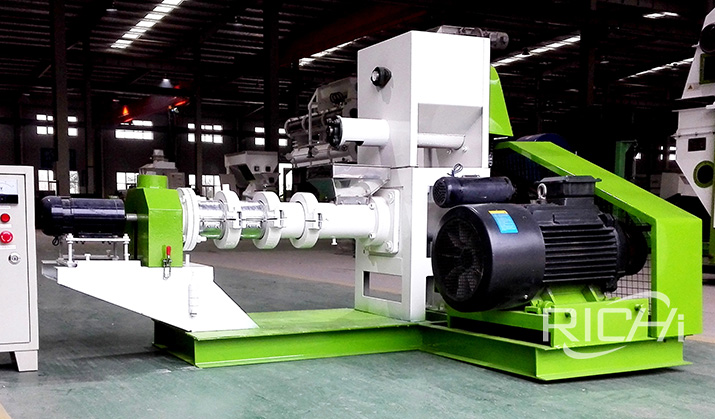

Extrusion System

The entire feed production process The main equipment used in the extrusion section is the pet food extruder. The pet food production line uses twin-screw feed extruder. The two-layer modulator has uniform modulation and high ripening degree. The gearbox uses SKF bearings and is equipped with a 110 kw main motor.

03

Drying System

The drying system uses a circulating belt drying system with a width of 2 meters. The fully open door structure is easy to clean and maintain. The heat exchange part uses aluminum fin structure, which is pressure-resistant and corrosion-resistant. After drying, the moisture content of feed pellets is reduced to below 13%.

04

Spraying System

In order to increase the fat content of extruded pet food pellets and improve the palatability of pet food pellets, spraying machine can be used in the pet food production process. This pet food production line uses vacuum spraying machine to spray fat onto the surface and inside of the feed pellets.

05

Packaging System

This pet food production line uses fully automatic packing system, equipped with packing scale, heat sealer, belt packing machine, automatic palletizer and other automatic packing systems to meet the packaging requirements of pet food pellets of different categories and bag types. The packed pet food pellets are convenient for sale.

06

CHINA PET FOOD PRODUCTION LINE CONFIGURATION

For the 2.5 T/H pet food production line in China, all equipment on this mill was independently developed and manufactured by RICHI Machinery. We offer quality guarantees and lifetime after-sales service.

The equipment used in this project includes crushers, a twin shaft paddle mixer, a single screw extruder machine, a mesh belt dryer, and vaccum sprayer and an automatic packing machine. These pet food production equipment were custom-designed to meet the production capacity of the 2.5 T/H pet food production line .

01

Crushing System

Hammer Crusher

02

Mixing System

Twin Shaft Paddle Mixer

03

Extrusion System

Single Screw Extruder

04

Drying System

Mesh Belt Dryer

05

Spraying System

Vaccum Sprayer

06

Packing System

Packing Machine

Complete PET FOOD PRODUCTION line delivery process

Machine Production

This is a pet food production line with a high degree of automation. The entire food production line uses high-quality carbon steel materials, and the main equipment on the feed production line, such as pet food extruders, belt dryer, vacuum spraying machine and other feed production equipment, use 304 stainless steel. Therefore, the feed pellet production equipment on this pet food production line is customized.

After signing a contract with the customer, our factory customizes production plan for pet food production equipment based on the design of the pet food production line.

The production cycle of this pet food production line is 60 days, which is two months. During these two months, we will regularly send customers pictures and videos of the finished feed production equipment or some semi-finished feed pellet machine, so that customers can understand the entire production process of the feed pellet machine they purchased.

Equipment Delivery

After all the feed pellet machine is produced within 2 months, we will deliver it according to the delivery time communicated with the customer in advance.

Delivery is a very important link. We have complete delivery process, and our feed production equipment has been exported to more than 140 countries and regions in the world. So no matter where your project is built, we can ensure that the feed pellet machine is delivered to your feed production project location.

Installation, Commissioning, and Training

After the feed pellet machine were delivered, we sent two engineers to the pet food production project site to provide installation guidance. After the installation was completed, we provided training and guidance to the staff of the pet food production plant. We have complete installation process, installation drawings, and detailed operating specifications, so the installation process for this customer was relatively smooth.

The warranty period of this pet food production line is one year. After the installation is completed, our after-sales team will contact the customer to communicate and solve problems related to the operation of the pet food production line.

One year is our warranty period, but even after one year, our after-sales service will still keep in touch with customers at any time. No matter what problems occur in the feed production equipment and what accessories are needed in the future, we will help customers solve them in time.

Since the location of the customer’s feed production project is not far from us, we often take our customers to visit the customer’s feed mill, so we have established a good relationship with the customer. When the customer encounters problems during the production process, they will communicate with us and get our response in time.

OUR PROJECTS IN OTHER COUNTRIES

The 2.5 T/H pet food production line in China has been running smoothly. This case of stable operation is the embodiment of RICH’s strength in the field of aquatic feed equipment for many years. All along, we have been focusing on the research and development of aquatic feed production equipment and the whole line delivery, and our business map has covered many markets around the world, including Russia, Kyrgyzstan, Kazakhstan, Azerbaijan, Bangladesh, Iran, India, Nigeria, and other countries and regions. With our reliable equipment quality and comprehensive service, we’ve earned long-term trust from global customers.

If you are planning a fish feed production line project, choose RICHI as your trusted partner. We will tailor professional equipment solutions and full-process technical assistance to help you launch operations quickly and achieve steady profits.

2.5 Tons/Hour Fish Feed Production Line In Kyrgyzstan

This project successfully overcame the specific requirements of feed extrusion technology in high-altitude regions, providing a cost-effective, localized feed solution for salmon and trout farming. It can make good use of local common corn and soybean meal, as well as local protein ingredients like flaxseed meal. By precisely controlling conditioning temperature and pelleting parameters, it produces feed pellets for sinking fish such as grass carp and rainbow trout.

3-5 tons/hour fish feed factory in Kazakhstan

Designed by RICHI, this 3–5 tons/hour fish feed production line features a twin-screw extruder and multiple grading screens. The biggest highlight is that the production capacity can be flexibly switched according to the market demand—running at full capacity of 5 tons/hour during peak season and dropping to 3 tons/hour during off-season. This not only saves energy but also reduces costs. This line can produce feed for both coldwater and freshwater fish.

5 tons/hour fish feed production line in Russia

This production line, which is built by our company and can produce floating feed pellets and sinking fish feed pellets, adopts advanced twin screw extrusion technology, and the produced feed pellets also have super water stability, which can be kept in water for 12 hours. This production line has made remarkable achievements since it was put into production.

1-2 tons/hour fish feed processing plant in Azerbaijan

Tailored to the aquaculture demands along the Caspian Sea, this production line allows for easy switching between sturgeon feed and conventional fish feed. Considering the high sand content of some raw materials in Azerbaijan, we’ve also added an impurity removal device to the line, significantly reducing wear and and enhancing machinery durability.

1 ton/hour Shrimp Feed Plant in Bangladesh

Bangladesh is a major shrimp exporter in South Asia, and the requirements for the pellet uniformity and water resistance stability of shrimp feed are strict. RICHI designed a 1 ton/hour shrimp feed plant for a local customer. This line adopted ultra-fine grinding technology and a double-layer conditioner to ensure uniform nutrition in feed particles and long water resistance, and to avoid the shrimp pond from being polluted by feed collapse when shrimps eat.

2 Tons/Hour Fish Feed Processing Plant in Nigeria

This processing plant features strong raw material adaptability and weather resistance, effectively tackling West Africa’s climatic challenges. It can make efficient use of cassava flour, palm kernel meal and other raw materials commonly used locally to produce high-quality feed that meets the needs of main varieties such as tilapia.

RICHI Guarantee

RICHI Machinery began as a professional manufacturer in feed pellet machine, and has now developed into a comprehensive solution partner for both feed pellet equipment and complete pellet plant systems. We take great pride in our team’s expertise and skills—from technical sales to process design engineers, every member is committed to supporting our customers. You can confidently choose RICHI to elevate your business.

In the field of aquatic feed pelletizing equipment and full aquatic feed pellet production lines, we leverage our team’s extensive experience to accurately understand your process engineering needs, deeply solve practical challenges, and tailor-made reliable solutions that meet international high standards for you.

Custom Design

Every customer’s production needs are unique, so we offer full custom design services. From production capacity and raw material type to product specifications, each production line is tailored to the customer’s actual conditions, ensuring efficient layout, optimized performance, and flexibility for future expansion.

Extensive Experience

Founded in 2013, our company has years of experience in the feed machinery industry. Whether it’s a stand-alone feed production machine or a turnkey feed production project, we can provide the perfect feed production solution.

Professional Service Team

From early consultation to solution design, equipment production, and after-sales service, we have a highly comprehensive and professional team whose members are fully committed to completing the project.

Competitive Advantage

We have a production facility covering over 60,000 square meters, and customers can visit our factory at any time. Our equipment has been exported to over 140 countries and regions worldwide, with very high customer satisfaction.

WHAT FEED PROCESSING SOLUTIONS CAN WE PROVIDE?

We can design and build complete feed pellet production lines and turnkey feed pellet machines with capacities from 1 to 100 tons per hour for all types of aquatic organisms and animals.

Aquatic Feed Production Line

Fish, shrimp, crab, shellfish and other conventional aquaculture species and special aquatic animals

Pet food production line

Cats, dogs, hamsters, turtles…

Poultry & Livestock feed production line

Chicken, duck, goose, pigeon, pig…

ruminant feed production line

Cattle, sheep, horses, deer, camels…

Multi-functional feed production line

Flexible switching between multiple categories