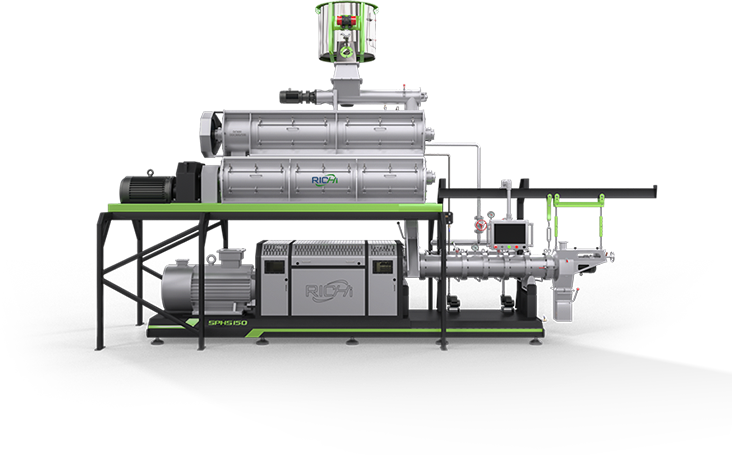

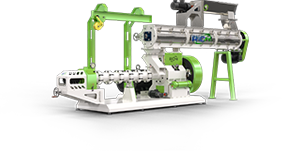

Wet Type Fish Feed Extruder

With RICHI’s wet type fish feed extruder, you can easily handle all kinds of feed formulas. It’s got a smart anti-clog design that makes production run way smoother, and every pellet comes out perfectly shaped, no mess. Using it for your farming is both worry-free and efficient.

Capacity

0.5-1T/H

Power

37-75 KW

Guide to Wet Type Fish Feed Extruder

In aquaculture, feed quality often determines whether fish grow fast or not, and it also directly affects the income of farmers. That’s why many fish farms and fish feed mills are thinking: How can we make good pellets with comprehensive nutrition, easy digestion and not easy to disperse in water? The answer is clear: wet extrusion technology. Compared to traditional dry-processing, wet-processing fully gelatinizes the starch in raw materials and creates a more balanced protein structure. This makes the feed more easily absorbed by fish and ensures that the pellets are more stable in water, resisting breakage.

Free from complicated steam system, this compact fish feed machine offers easy controls anyone can master quickly. It produces feed: balanced nutrition, uniform in size, and easy to digest – helping animals grow faster and healthier. And its dry extrusion process means zero steam boiler requirements, reducing investment costs and running expenses. For fish farmers or fish feed mills with limited budgets and moderate production needs, the dry type fish feed pelletizer is the perfect choice.

At RICHI, we focus on developing fish feed equipment that stands the test of practical aquaculture. If you’re looking for a mature and reliable fish feed production solution to make high-quality feed suitable for fish and shrimp, try our wet type fish feed extruder — making good feed your own way.

How the Wet Type Fish Feed Extruder Works

If you’re curious about how it works, let’s first take a look at its components. This wet type fish feed machine primarily consists of a feeding device, conditioner, screw (you can choose how many screws), pressure chamber, forming template, cutter, and a drive and control system.

After understanding these parts, let’s follow the process step by step to see how raw materials are transformed into fish feed.

When it’s running, first you feed in the raw materials mixed according to the formula. Steam warms them up and adds moisture, making the materials soft. Then the screw pushes the softened stuff into a high-temperature, high-pressure extrusion chamber. That’s when the starch starts to gelatinize and the protein changes – the loose raw materials slowly blend into a smooth, thick mixture.

Next, this mixture gets squeezed through the die under pressure, turning into continuous feed strips. Just after leaving the mold, the internal pressure drops suddenly, and the moisture turns into steam and escapes, making the feed pellets soft and porous. Finally, a high-speed rotating cutter cuts these strips into pre-set pellets – and that’s your final fish feed.

The secret of the wet-process is how “steam conditioning” and “screw extrusion” work together. Steam fixes the problem of raw materials being too dry, avoiding the troubles of hard raw materials, energy consumption, and difficulty in forming with dry extrusion. Plus, high temperature and high pressure fully cook the raw materials. And by adjusting the die size, screw speed, and steam amount, you can easily control the pellet density and hardness – making floating, slow-sinking, or sinking pellets that work for all kinds of fish and shrimp.

Wet Type Fish Feed Extruder Features

A good piece of equipment isn’t about having too many complex functions, but rather being reliable and easy to use in key areas. RICHI wet type fish feed extruder is just such a machine. Its design keeps in mind what fish farmers and feed factories actually need, making daily operation more convenient, maintenance no longer laborious, and production both worry-free and practical.

01

Advanced Pellet Structure

Adopting international advanced pelleting technology and equipped with soft knife speed regulation function, you can flexibly adjust the pellet length according to the actual production demand.

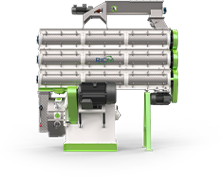

02

Wear-Resistant Materials

The screw sleeve and screw are made of special alloy steel. They don’t wear out easily, even with high temperatures or long hours of use. That way, you won’t have to worry about maintenance issues frequently in daily production.

03

Easy Part Replacement

The die plate design is very convenient. It is effortless to change different hole size or adjust the pellet size, which can help you save a lot of time.

04

Adjustable Feeding Speed

Equipped with a variable-speed feeder, you can adjust the feeding speed at any time according to the raw material status and production. That keeps the feed distributed more evenly, and you won’t have to worry about clogs either.

05

Unique Design

The overall design takes your daily use into consideration. It is easy to disassemble and clean, and maintenance is no longer troublesome, saving both labor and time.

06

Wide Application range

No fussy demands on raw materials. It can process everything from grains and beans to animal protein. Even special materials like feather meal or rice husks, it handles them with no problem at all.

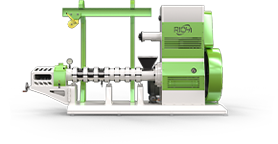

Wet Type Fish Feed Extruder Technical Specifications

| Model | Capacity (T/H) | Main Power (KW) | Feeding Power (KW) | Cutting Power (KW) | Dia. of Screw (MM) |

| DSP90-B | 0.5-0.6 | 37 | 7.5 | 1.1 | Φ90 |

| DGP135-B | 1.0-01.2 | 75 | 7.5 | 1.5 | Φ135 |

We currently offer two standard models of wet extruders. If the production capacity or configuration doesn’t meet your needs, we also support customization upon request.

Benefits Of Wet Type Fish Feed Extruder

Choosing a wet type fish feed extruder isn’t just about making high-quality feed – it’s about making your farming business run smoother and easier. The advantages it brings are not only reflected in the product quality, but also make your production more steady, energy-saving and more flexible.

Applications of Our Wet Type Fish Feed Extruder

Wet type fish feed extruder is a powerful tool in aquaculture and pet feed production, especially in high-quality feed production environments, it’s absolutely essential. No matter how many kinds of raw materials you have on hand, or how complex the nutritional needs of different animals are, this flexible and reliable equipment can help you handle it easily.

Suitable Raw Materials

In real production, different raw materials bring different challenges. But the wet type fish feed extruder, with its flexible moisture and temperature control, handles all kinds of complex materials easily. Whether it’s damp fish meal, sticky soybean meal, or crumbly corn flour, it gets the job done reliably. For farmers, that means no more worrying about varied raw materials or seasonal changes—you can focus on mixing up the perfect formula for your fish, keeping the feed quality consistent all the time.

corn

wheat

bean

bran

grass meal

meat and bone meal

Suitable Animals

Many people know that fish feed extruders are mainly used to make fish feed, and that’s totally true. But RICHI’s wet type fish feed extruder machine can do more! It can not only produce nutritious feed suitable for shrimp, cats, dogs, birds, rabbits, foxes and other animals, but also make ornamental fish feed, bait and even feed specially prepared for fry.

flatfish

eel

sea bass

catfish

crab

penaeus shrimp

dog

cat

Applicable Customers

The feed made by dry extruders is usually hard and dense, with low water solubility. it is commonlyused in making fish feed. The machine can adjust the size and shape of the feed, and controlwhether it floats or sinks. This helps meet the eating habits of different aquatic animals like fish,shrimp, and crabs, it can also be used to make feed for many land animals. The machine settingscan be changed based on what kind of animal feed you need.

24/7 live customer support

Clearly describe your information needs

Large-scale Fish Feed Factory

Professional Aquaculture Farms

Pet Feed Processing Plants

Angel Investors

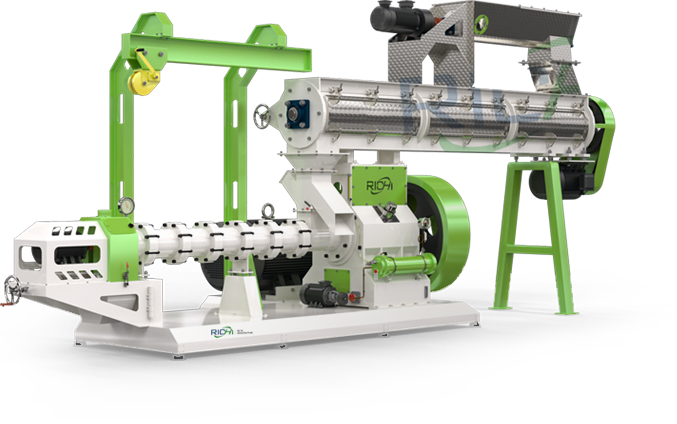

A Complete Fish Feed Production Line

A typical fish feed production line usually includes steps like raw material preparation, mixing, pelleting, drying, cooling and packaging. Scientific and reasonable process design can not only make the production efficiency rise, but also control the product quality steadily, and also control the cost skillfully, so that enterprises can be confident in the market competition.

We have been in aquatic feed industry for many years, knowing that each farm and processing plant has its own unique needs and challenges. With accumulated experience and solid technical foundation, RICHI team can tailor the most suitable production plan for you, help you build an efficient, stable and sustainable fish feed production line, and make your breeding career more confident and secure.

Essentail Equipment for a Complete Fish Feed Production Line

A complete fish feed production line requires multiple pieces of equipment to work together. From raw material processing to finished product packaging, each link has dedicated machinery to ensure efficiency and quality.

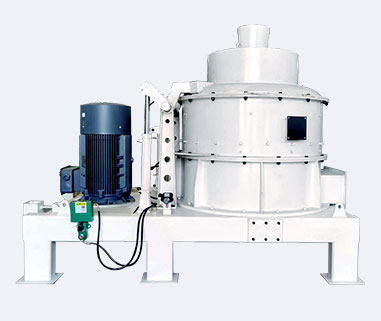

Hammer Mill

Mixer

Ultrafine Grinder

Cooler

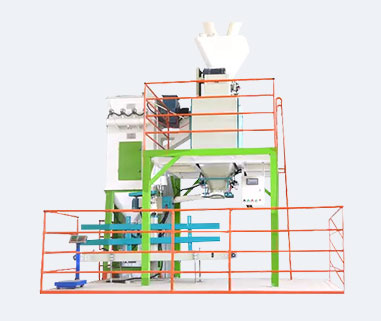

Packaging Equipment

Spray

Dryer

Silo

Global Projects Using RICHI Fish Feed Extruders

Whether in fish farms in Africa, fish feed processing plants in Southeast Asia, or professional feed mills in the Middle East and Europe, you can see them working silently. Every project is the result of our joint efforts with our customers, and also a testament to our mutual trust.

Iran

Iran – Wet Type Fish Feed Extruder

This project uses a wet extruder with a capacity of 1,000 kg/h.

Ghana

Ghana – Wet Type Fish Feed Extruder

This project uses a wet extruder with a capacity of 800 kg/h.

Bangladesh

Bangladesh – Wet Type Fish Feed Extruder

This project uses a wet extruder with a capacity of 500 kg/h.

Indonesia

Indonesia – Wet Type Floating Fish Feed Extruder

This project uses a wet extruder with a capacity of 1t/h.

Russia

Russia – Wet Fish Feed Extruder

This project uses a wet extruder with a capacity of 2 – 3t/h.

USA

USA – Floating Fish Feed Extruder Machine

This project uses a twin-screw wet extruder with a capacity of 2,000 kg/h.

Germany

Germany – Wet Type Feed Extruder for Sale

This project uses a wet extruder with a capacity of 1,500 kg/h.

Kyrgyzstan

Kazakhstan – Wet Extruder Machine

This project uses a wet extruder with a capacity of 4t/h.

About RICH Machinery

—— A Professional and Leading Manufacturer

As a leading manufacturer of feed pellet production equipment, RICHI Machinery has become a recognized brand in the industry after decades of continuous innovation and growth. We always puts customers first and are committed to providing advanced and efficient production solutions. So far, our equipment and services have reached more than 130 countries, helping more than 2,000 projects to land successfully, and winning trust and support from clients worldwide.

Whether you need sinking feed or floating feed, from ultra-fine particles to large pellets, our extrusion processing system can flexibly meet all your needs. Our equipment ensures that the pass rate of product granularity is over 95%, which helps you to easily realize high-quality production. At the same time, the system design is flexible enough for you to adjust the product type in your business development without sufficient extra investment. We offer:

Consulting and Engineering Planning

We will talk with you to get your production needs and targets, and then, our experienced engineers will take over. They will design a customized, efficient, advanced factory building solution suitable for your future development.

Project Management Support

From initial design and planning to the later equipment installation, commissioning, and after-sales maintenance, we follow up the whole process. Ensure the entire project runs smoothly and finishes on time.

One-Stop Turnkey Project

Our services for fish feed mill construction cover the entire process, from raw material input to finished product packaging. You just need to “turn the key” and start production. The system is efficient and stable, helping you improve efficiency, reduce costs, and save time and effort.

Other Feed Production Equipment

We also have other feed production equipment options, each one’s designed for different uses, and they’ll help you solve specific production needs.

High quality, multi-functional, reliable

High quality, multi-functional, reliable

High quality, multi-functional, reliable

Frequently Asked Questions

If you have any questions about extruders or feed production, you can first take a look at these answers.

1. I want to know which fish or other aquatic animals might be best suited for wet-processed feed?

+

Usually, aquatic creatures like tilapia, catfish, and shrimp are particularly well-suited for feed made by wet fish feed extruders. These species have higher requirements for feed digestibility and nutrition. The wet process, combined with steam treatment, makes the protein and fat in the feed easier to absorb while retaining more nutrients. This not only helps them grow better but also boosts farming efficiency – perfect for large-scale, commercial aquaculture operations.

2. I don’t know much about fish feed production lines. How can I choose the right machines?

+

If you’re not familiar with fish feed production lines, picking the right equipment can start with a few key points. First, be clear about your production needs: like whether you’re making sinking or floating feed, your daily output requirements, pellet size, and so on. Then, get to know what a full production line includes – things like crushing, mixing, pelletizing, drying, and packaging. Each step needs the right equipment to back it up.

Of course, if you really don’t know where to start, just tell our sales team. They’ll give you the best solution from a professional standpoint.

3. Which countries do you sell your products to?

+

Our wet type fish feed extruders have been exported to over 140 countries and regions, like the US, Canada, Australia, Russia, Mexico, India, the UK, Uzbekistan, South Africa, Afghanistan, Kenya, Tanzania, Algeria, Morocco, Sudan, Saudi Arabia, Malaysia, Indonesia, the Philippines, and so on.

4. Is this equipment difficult to operate? My staffs don’t have much technical backgrounds — can they learn?

+

We designed our wet fish feed extruder with ease of use in mind. It comes with an intelligent control system, featuring a straightforward interface and simple operations. Even non-technical staff can quickly get the hang of basic operations and daily maintenance after the professional training we provide. We also offer on-site guidance and remote technical support to make sure you and your team can get up and running smoothly, with complete peace of mind.

5. I’m worried about high operating costs. How does the wet process perform in terms of energy use and raw material utilization?

+

While wet type equipment does have slightly higher initial investment and energy use compared to dry type ones, it has clear advantages when it comes to feed quality, nutrient retention, and digestibility. Modern wet type extruders use energy-efficient technology – they can smartly adjust energy consumption based on production needs, avoiding waste.

At the same time, the wet process makes better use of starches and proteins in raw materials, boosting pellet formation rates and overall yield. That improves raw material utilization across the board. In the long run, this helps lower unit costs and boost economic returns.

6. How to confirm if this equipment is right for my business? Are there any success stories I can look at?

+

To make sure our wet type fish feed extruder fits your needs perfectly, we’ll first dig into the details of your farm—like what species you’re raising, the scale of your operation, your expected output, and so on. With that info, we can tailor a solution that’s just right for you. What’s more, we can arrange on-site visits or video calls so you can chat directly with our technical experts, get any questions answered, and see detailed equipment specs and simulated production data to help you make the best call.

As for case studies, we’ve done over 2,000 projects in more than 130 countries and regions, covering all kinds of farms—big and small, different types. There’s the fish feed production line in Germany, the fish feed factory in Indonesia, the one in Uzbekistan… and there are tons more. We can recommend relevant cases based on your specific situation. And if possible, we can even connect you with other users so you can get first-hand experience from them.