FISH FEED MACHINE

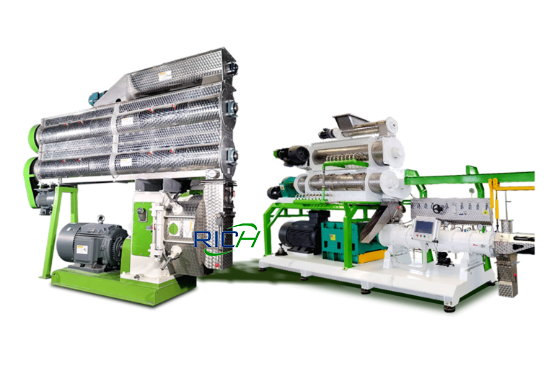

Fish feed machine is a specialized machine designed for producing fish/shrimp feed. It serves as the core equipment in fish/shrimp feed processing.

As a professional fish feed machine manufacturer, RICHI can offer you fish feed pellet machine and fish feed extruders amd more.

FISH FEED MACHINE TYPES

Many people want to produce fish/shrimp feed pellets, but there is more than one type of fish feed machine. Different farming needs, feed formulas and aquatic animal species determine that we need different types of pelleting equipment to match.

RICHI provides a variety of efficient and durable fish feed making machines, which can meet the different production needs from individual-scale farming to large-scale feed mills.

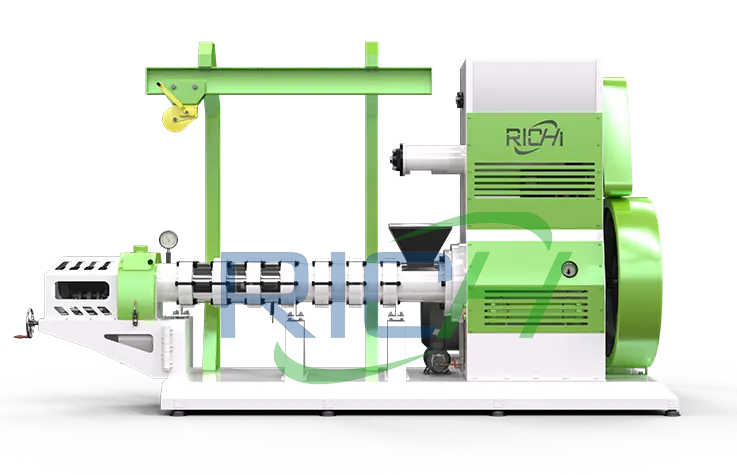

Dry Type Extruder

Can produce feed for bottom-dwelling fish (e.g., grass carp, black carp, and carp) and pet snacks (e.g., chew sticks, hard pellet dog food). Suitable for beginners in the aquaculture industry.

Capacity

0.3-12

T/H

Power

37-355

KW

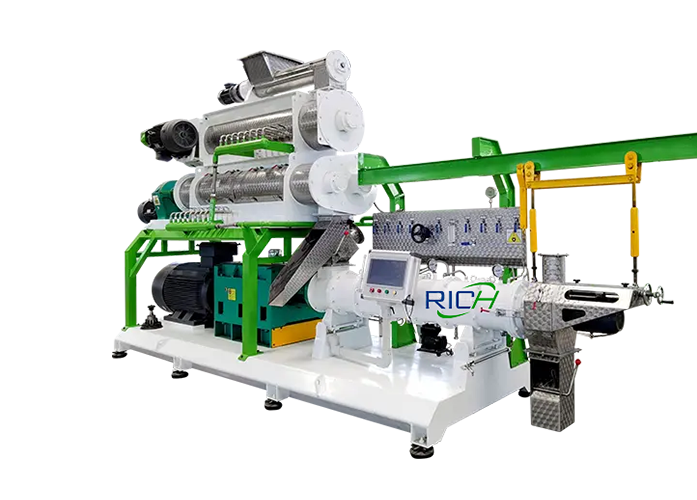

Wet Type Extruder

Producing high-moisture feed pellets by “steam conditioning + screw extrusion”. Fish/shrimp feed from it is a bit better than from dry type extruders.

Capacity

0.3-5

T/H

Power

37-132

KW

Single Screw Extruder

Suitable for processing common cereal grains (corn, wheat, sorghum) and low-fiber, low-fat ingredients (soybean meal, cottonseed meal). Forms a complementary “basic vs. high-end” positioning alongside twin screw extruder.

Capacity

0.3-12

T/H

Power

37-355

KW

twin screw extruder

RICHI twin screw extruder can make floating, slow-sinking, sinking feeds for fish/shrimp/crabs, and dog/cat food. It handles high-fiber, high-fat, and high-moisture ingredients.

Capacity

0.5-12

T/H

Power

55-355

KW

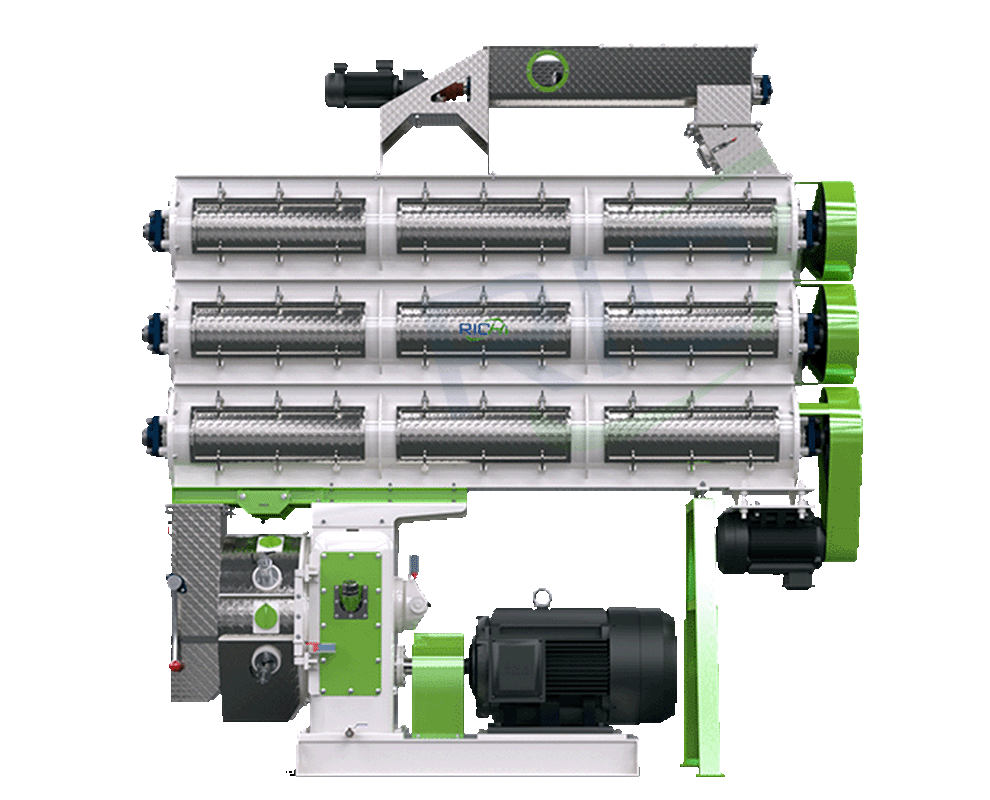

Fish Feed Pellet Machine

Mainly used for sinking fish feed, shrimp feed, and crab feed. Floating fish feed (requiring expansion process) is outside this equipment’s production scope.

Capacity

0.6-30

T/H

Power

22-355

KW

Fish Feed Extruder Machine

Fish feed extruder can produce floating, sinking, and slow-sinking feeds. Perfect for mixed-culture farming scenarios.

Capacity

0.5-12

T/H

Power

55-355

KW

Floating Fish Feed Machine

This fish feed machine supports customized production of high-density feed–from high floatability to slow-sinking (suspension). It meets the feeding needs of bass, catfish, trout, tilapia, and some ornamental fish.

Capacity

0.5-12

T/H

Power

55-355

KW

Sinking Fish Feed Machine

Produce feeds that quickly sink to the bottom or mid-lower water layers. The sinking pellets are dense and durable, resisting disintegration from water currents. Suit for bottom-feeding fish.

Capacity

0.6-30

T/H

Power

22-315

KW

FISH FEED MACHINE APPLICATION

Different fish species live at different water depths and have different feeding habits, so fish feed pellets are designed with various properties. For example, floating feed pellets suits surface-feeding fish; Sinking feed pellets quickly drop to the bottom; And slow-sinking feed pellets target mid-water species.

Producing these diverse feed types relies on advanced fish feed processing equipment. With professional fish feed machines, pellet density and sinking speed can be precisely controlled.

Floating feed for salmon

Floating feed for tilapia

Sinking feed for catfish

Sinking feed for eel

Slow-sinking feed for trout

Slow-sinking feed for bass

Fish Feed Machine for Multiple Animal Feed production

Fish feed machines can not only produce a variety of fish feeds, but are also suitable for the production of aquatic animal feeds such as shrimp and shellfish. And can even meet the production needs of cat and dog pet food.

By using professional aquatic fish feed machines or multi-functional pellet feed production equipment, users only need to replace different-sized molds and adjust the corresponding processing parameters, and can flexibly produce high-quality pellet feed that meets the nutritional needs of different animal species, growth stages and varieties.

Fish feed machine 4 application scenarios

We offer various specialized feed production solutions–different from single-function standalone machine—where each production line is a comprehensive system covering crushing, mixing, pelletizing/extrusion, drying, spraying, cooling, etc.(→Click the title to jump to the corresponding page.)

Matching Production Lines with 5 applications

Fish Feed Machine Solutions for Small to Large Feed Factories

Currently, we offer standard fish feed mill solutions for various scales (→see specific capacities below). For your unique production needs (such as ultra-large-scale mass production or customized small-batch dedicated lines), RICHI can also provide customized feed production capacity configuration solutions.

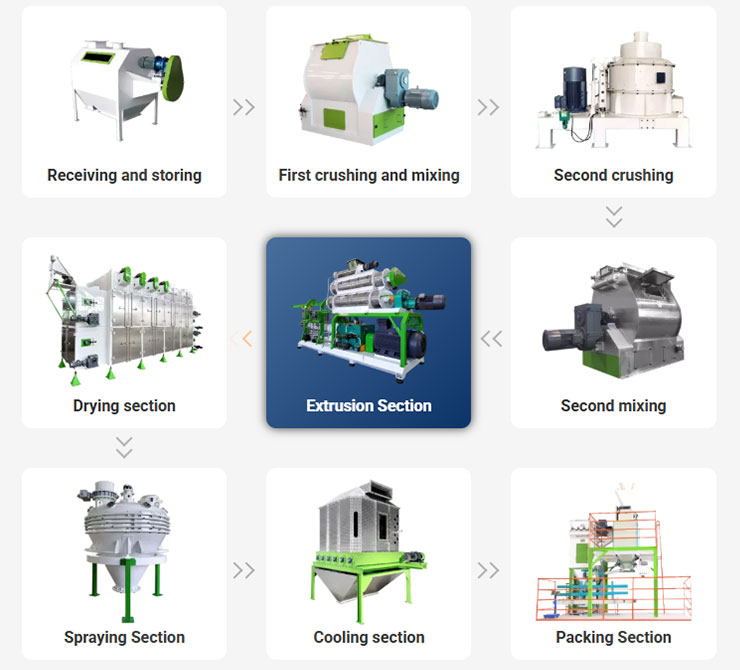

PROCESS IN HIGH-QUALITY FISH FEED PELLET MAKING

The general fish feed production process includes: receiving and cleaning raw materials – crushing and mixing – pelleting or extruding- drying – spraying – cooling and packaging.

This is the most common way fish feed is made. However, different fish feed plants may change the fish feed production process based on their needs. For example, some make feed for specific types of fish, while others focus on higher output. These needs can affect how the fish feed production process is set up.

Fish feed granulation process

fish feed production section Description

Receiving and Cleaning Raw Materials

+

Receive and prepare raw materials such as grains, soybean meal, fish meal, and oils. Remove impurities to make sure the materials are clean and of good quality.

Crushing and Mixing

+

Break large pieces into small powder. Then mix all the materials in the right amounts using a mixer. This makes sure the nutrition is evenly spread in every feed pellet.

Pelletizing or Extruding

+

Turn the mixed material into feed pellets. Depending on the product type, use either a feed pellet machine for regular pellets or an extruder for floating or sinking aquafeed.

Drying

+

Newly made pellets often have high moisture. Use a dryer to reduce water content to a safe level. This helps prevent mold and keeps the feed fresh for longer.

Spraying

+

After drying, spray oil, vitamins, amino acids, or other nutrients onto the surface of the pellets. This step is also known as “post-spraying” and helps improve taste and nutrition.

Cooling & Packaging

+

The pellets remain hot after drying and need to be cooled to near room temperature with a cooler. Only then are they screened to remove fines, followed by automatic weighing and packaging as per customer requirements.

If you have your own fish feed production plan or special requirements, please feel free to let us know. Whether you’re looking for a right fish feed machine or want to improve your current production line, we are happy to offer professional advice and customized solutions.

Fish Feed Production Equipment

To make high-quality and efficient fish feed, a set of professional and complete fish feed processing equipment is very important. From raw material processing to finished product packaging, each link requires appropriate equipment to ensure good feed nutrition, good pellet forming, and stable production process.

We are an experienced fish feed equipment supplier and can provide you with a full fish feed production system support.

Fish Feed Machine in Action: Production Line Examples

Ecuador

Cote d’lvoire

Indonesia

We have Perfect service

Plan & Document

Design & Measure

Install & Maintain

Deliver & Ship

Cooperate & Support

MEET RICHI MACHINERY

RICHI Machinery has always been a leader in the pellet equipment industry. This is because we provide good customer service. We also build trust and teamwork with our clients. Our goal is to offer advanced and efficient feed production solutions.

In fish feed processing, it is important to understand each customer’s needs. Richi Machinery works hard to provide world-class feed plant solutions. We want to help our customers use machines with lower costs and higher efficiency. We also want to support their growth and development in the industry.

Design & Planning

Project Execution

Manufacturing & Production

Installation & Commissioning

After-sales Service

30+

Years Of Experience

60000㎡

Factory Area

140+

Countries

1000+

Projects